Method for revamping a high pressure melamine plant

A technology for melamine and equipment, applied in the field of purification section of high-pressure melamine equipment, can solve problems such as unfavorable cost and high steam consumption of a stripper, and achieve the effect of eliminating steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

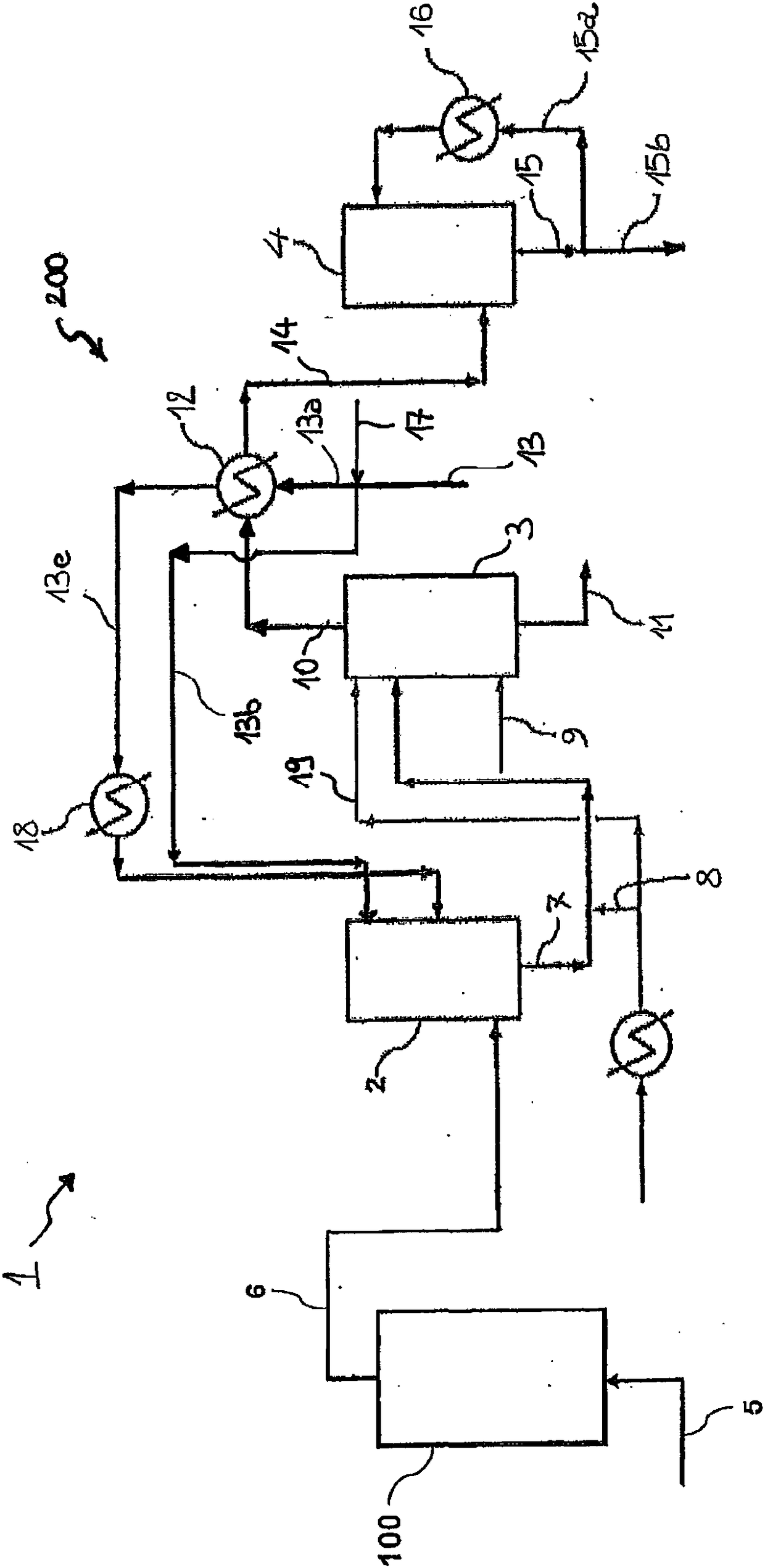

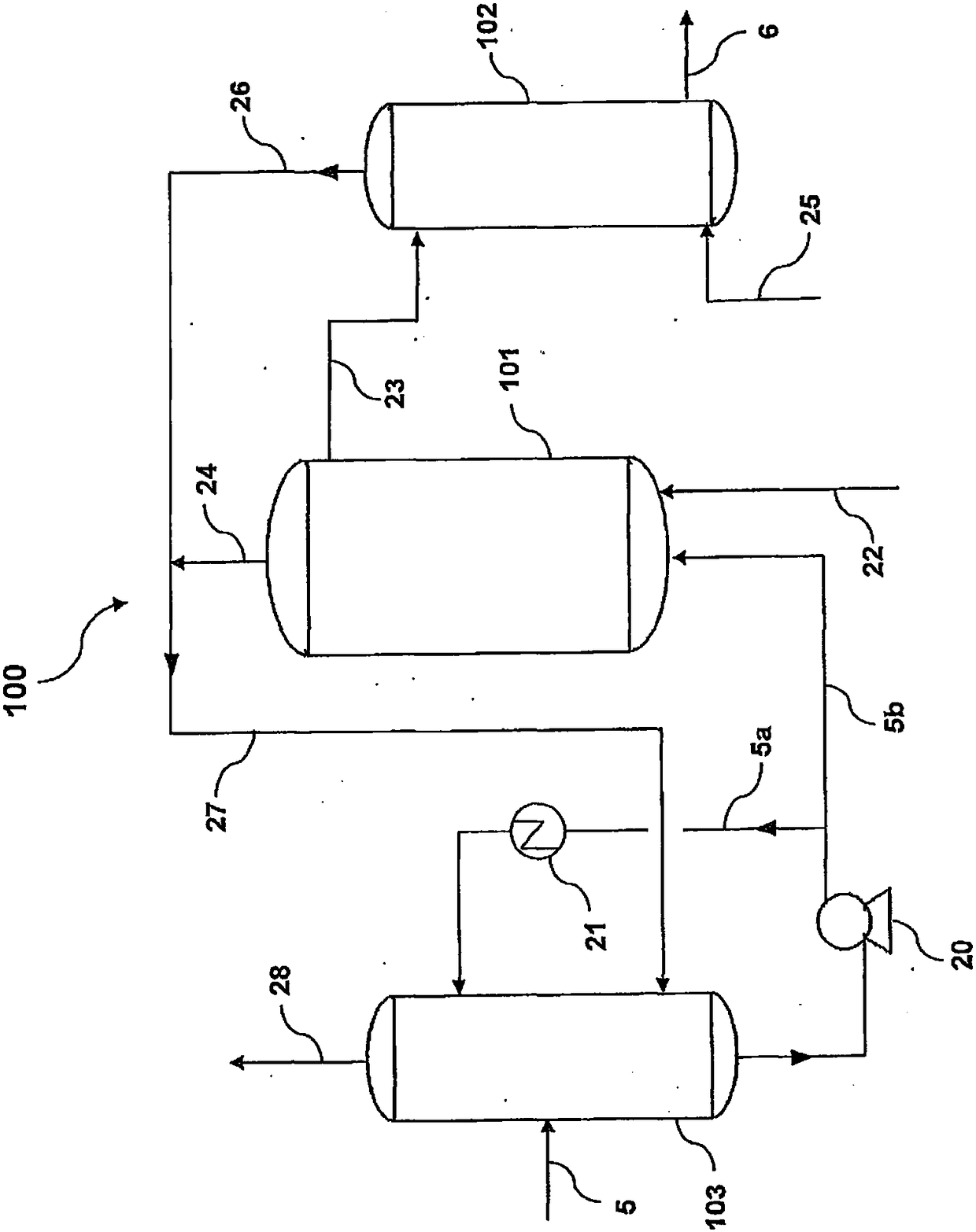

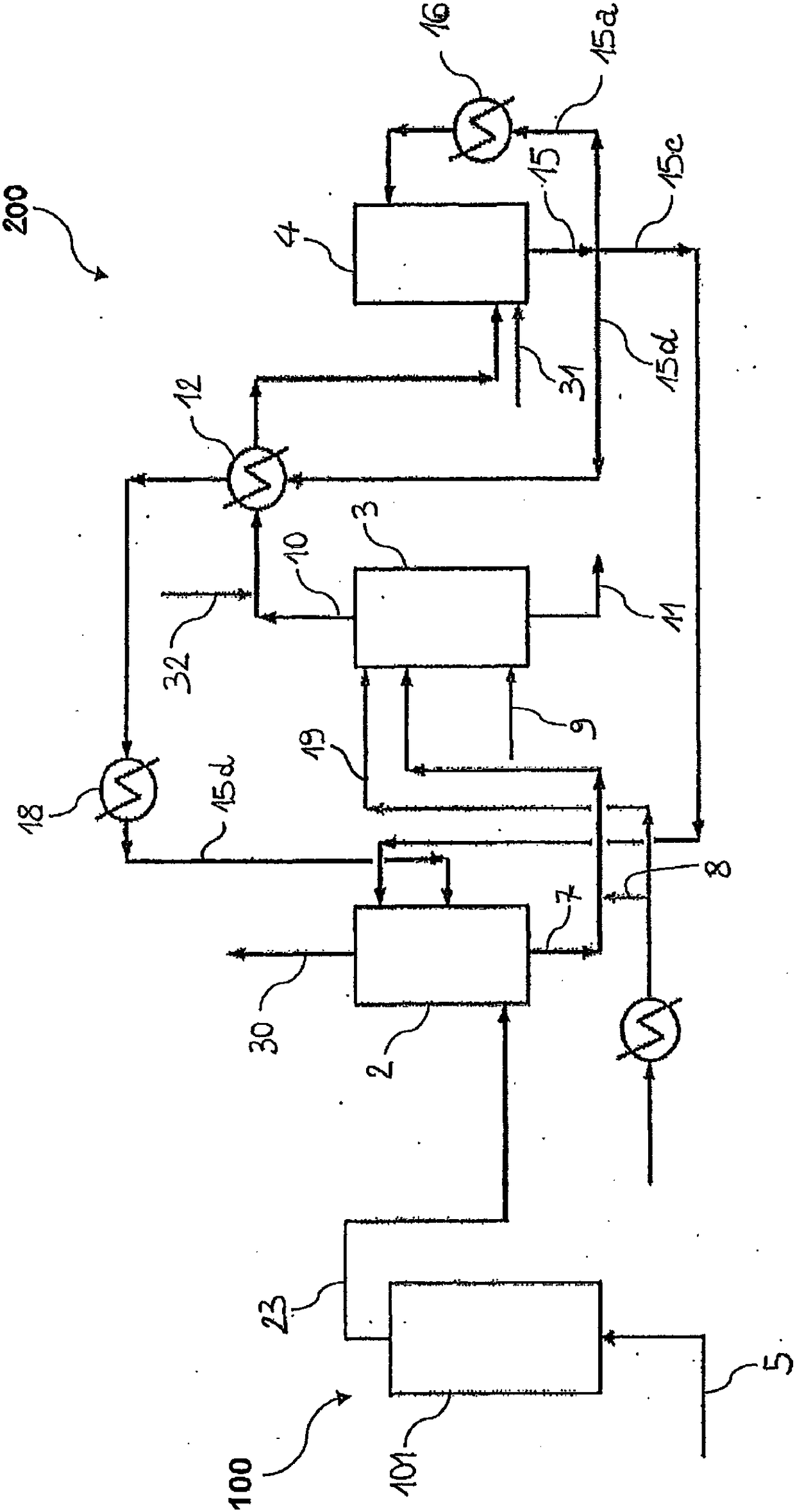

[0062] see figure 1 , The melamine plant 1 includes a high pressure section 100 and a purification section 200, the purification section 200 operates at significantly lower pressure and temperature.

[0063] The high-pressure section 100 is fed with a urea melt 5 to produce melamine 6 . When the melamine 6 leaves the high pressure section 100 , the pressure drops from above 7 MPa to 0.4-2 MPa and the melamine is supplied to the purification section 200 .

[0064] The purification section 200 mainly includes a quencher 2 , a stripper 3 and an absorber 4 . In the quencher 2, the melamine 6 is treated with an aqueous solution of ammonia 13c, 13b at about 160° C. to dissolve the melamine. The melamine collected from the bottom of the quencher 2 is fed to the stripper 3 as an aqueous solution 7 further diluted with a water stream 8 from the plant.

[0065] The stripper 3 is also fed with steam 9 and also with another water stream 19 from the plant, preferably from the plant. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com