Flotation impurity-removing method for asbestos-containing talcose ore

A technology for talc ore and asbestos, applied in flotation, solid separation, etc., can solve the problem of asbestos being difficult to remove, and achieve the effects of low cost, good foaming, and good mineral selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

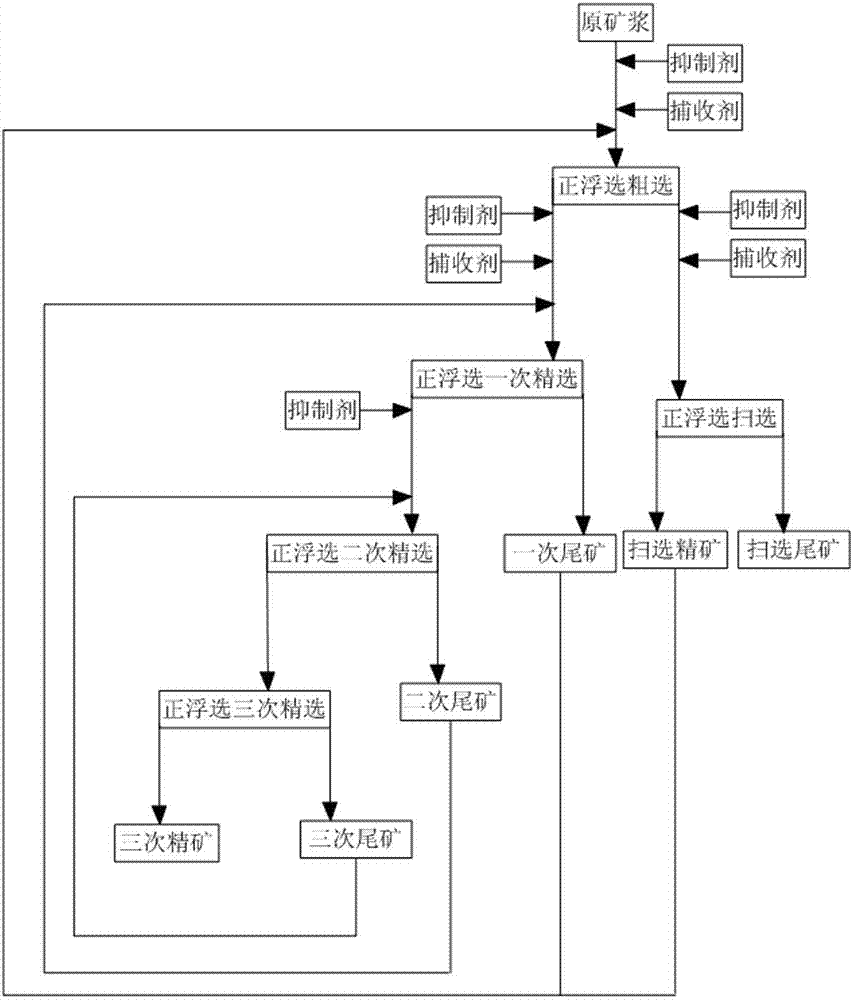

Method used

Image

Examples

Embodiment 1

[0031] The composition of the selected asbestos-containing talc ore is SiO by weight percentage 2 55.07%, MgO31.21%, CaO4.82%; Fe 2 o 3 0.10%;Al 2 o 3 0.32%; the balance is impurities; the weight content of talc is 78.5%, the weight content of tremolite is 9%, the whiteness is 92%, and it contains asbestos fibers through polarizing microscope detection;

[0032] Use XMCQФ180×200 porcelain ball mill to grind asbestos-containing talc ore until the fineness is less than 0.074mm, accounting for 90% of the total weight of all materials, and then add water to make raw ore pulp with a weight concentration of 20%;

[0033] Put the raw ore in the flotation equipment, add NaOH to adjust the pH value to 10.8 under stirring conditions, then add the inhibitor phytic acid and stir for 4 minutes, the amount of phytic acid added is 200g / t raw ore pulp, and then add collector ten Sodium dialkylbenzenesulfonate and stirring for 4min, the addition of sodium dodecylbenzenesulfonate is 250g...

Embodiment 2

[0045] The composition of the selected asbestos-containing talc ore is SiO by weight percentage 2 54.5%, MgO 30%, CaO 4.5%; Fe 2 o 3 0.15%;Al 2 o 3 0.35%; the balance is impurities; the weight content of talc is 77.2%, the weight content of tremolite is 8%, the whiteness is 93%, and it contains asbestos fibers through polarizing microscope detection;

[0046] Use XMCQФ180×200 porcelain ball mill to grind asbestos-containing talc ore until the fineness is less than 0.074mm, accounting for 80% of the total weight of all materials, and then add water to make the weight concentration 15% raw ore pulp;

[0047] The raw ore will be placed in the flotation equipment, under the condition of stirring, firstly add NaOH to adjust the pH value to 11.1, then add the inhibitor phytic acid and stir for 3 minutes, the amount of phytic acid added is 150g / t raw ore pulp, then add collector Sodium dialkylbenzenesulfonate and stirring for 3min, the addition of sodium dodecylbenzenesulfona...

Embodiment 3

[0059] The composition of the selected asbestos-containing talc ore is SiO by weight percentage 2 55.5%, MgO 30.6%, CaO5%; Fe 2 o 3 0.13%;Al 2 o 3 0.33%; the balance is impurities; the weight content of talc is 78.2%, the weight content of tremolite is 7%, the whiteness is 94%, and it contains asbestos fibers through polarizing microscope detection;

[0060] Use XMCQФ180×200 porcelain ball mill to grind asbestos-containing talc ore until the fineness is less than 0.074mm, accounting for 75% of the total weight of all materials, and then add water to make the weight concentration 25% Crude pulp;

[0061] The raw ore will be placed in the flotation equipment, and NaCO will be added under stirring conditions 3 Adjust the pH value to 10, then add the inhibitor phytic acid and stir for 4 minutes. The amount of sodium acid sodium added is 230g / t raw ore pulp; then carry out 4min forward flotation roughing to obtain roughing concentrate and roughing tailings; stirring speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com