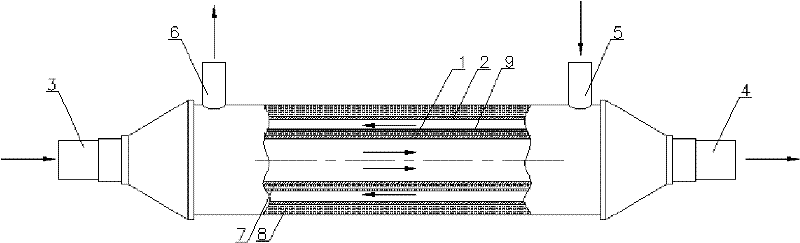

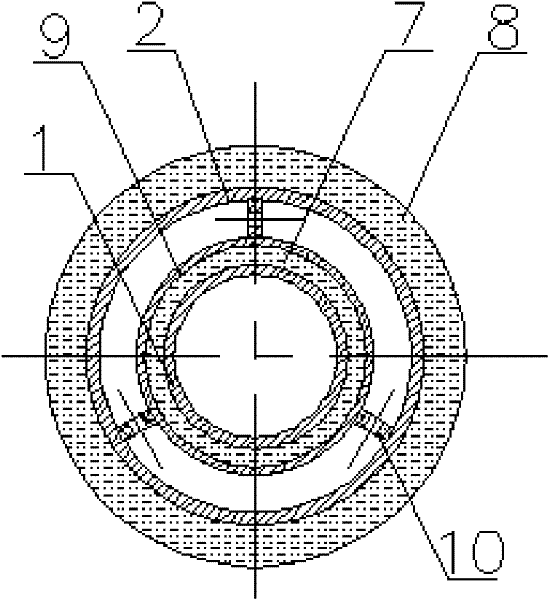

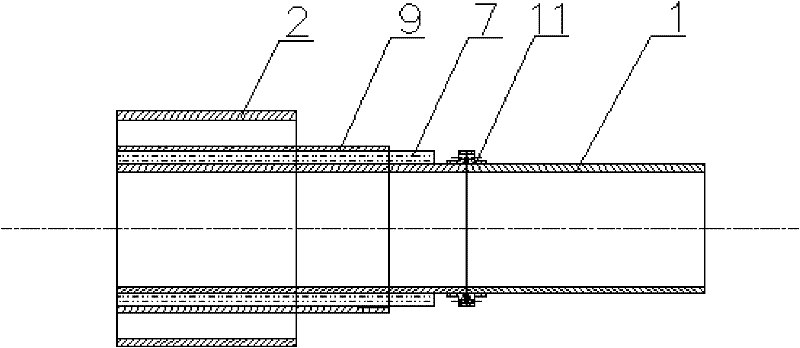

Heat-supply three-layer casing system based on countercurrent heat exchange principle

A bushing and principle technology, applied in heat exchange equipment, protecting pipelines and pipes through heat insulation, can solve the problems of large heat dissipation, heat waste, and large heat dissipation of heat pipes, so as to avoid waste, reduce losses, reduce Effect of small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: The thermal insulation material is asbestos wool, the thermal conductivity is 0.077W / (m K), the heating distance is 10,000 meters, the ambient temperature is 0°C, the steam temperature of the hot fluid outlet of the heating source section is 255.8°C, and the pressure is 4 ×10 -4 Pa, the mass flow rate is 10kg / s, and the outlet temperature of the cold fluid at the hot end is 130°C.

[0029] (1) If the traditional heat supply pipeline is used, the pipeline for conveying hot fluid and the pipeline for returning cold fluid are respectively set up, the outer diameter of the pipeline is 150mm, and the thickness of the insulation layer is 60mm. Let the inlet temperature of the thermal fluid at the hot end be t 1 , then the average temperature of the pipeline is In order to simplify the calculation, it is considered that the thermal resistance of the pipe wall is negligible compared with the insulation layer, and the average temperature of the pipe is used for cal...

example 2

[0074] Example 2: The insulation material is asbestos wool, the thermal conductivity is 0.077W / (m K), the heating distance is 10,000 meters, the ambient temperature is 0°C, the steam temperature of the hot fluid outlet of the heating source section is 255.8°C, and the pressure is 4 ×10 -4 Pa, the mass flow rate is 10kg / s, and the outlet temperature of the cold fluid at the hot end is 50°C.

[0075] (1) If the traditional heat transfer pipeline is used, the pipeline for conveying hot fluid and the pipeline for returning cold fluid are respectively set up, the outer diameter of the pipeline is 150mm, and the thickness of the insulation layer is 60mm. With the calculation method in Example 1, after multiple iterations, the inlet temperature t of the thermal fluid at the heat user end can be obtained 1 =221.3℃, the average temperature of the outer wall surface of the thermal fluid pipe insulation layer is t 2 =43.2℃, heat loss Φ 热 =1698897W.

[0076] In the same way, it can be...

example 3

[0078] Example 3: The insulation material is asbestos wool, the thermal conductivity is 0.077W / (m K), the heating distance is 10,000 meters, the ambient temperature is 20°C, the steam temperature of the hot fluid outlet of the heating source section is 255.8°C, and the pressure is 4 ×10 -4 Pa, the mass flow rate is 10kg / s, the outlet temperature of the cold fluid at the hot end is 130°C, and the pressure is 2.7×10 5 Pa.

[0079] (1) If the traditional heat transfer pipeline is used, the pipeline for conveying hot fluid and the pipeline for returning cold fluid are respectively set up, the outer diameter of the pipeline is 150mm, and the thickness of the insulation layer is 60mm. With the calculation method in Example 1, after multiple iterations, the inlet temperature t of the thermal fluid at the heat user end can be obtained 1 =225.7℃, the average temperature of the outer wall surface of the thermal fluid pipe insulation layer is t 2 =60.4℃, heat loss Φ 热 =1436699W. 269...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com