Directly-heated electric water heater

An electric water heater, direct heating technology, applied in the field of direct heating electric water heaters, can solve the problems of high manufacturing, transportation and installation costs, inability to achieve absolute heat preservation, power waste, etc., to achieve convenient transportation, simple and easy installation, and improved high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

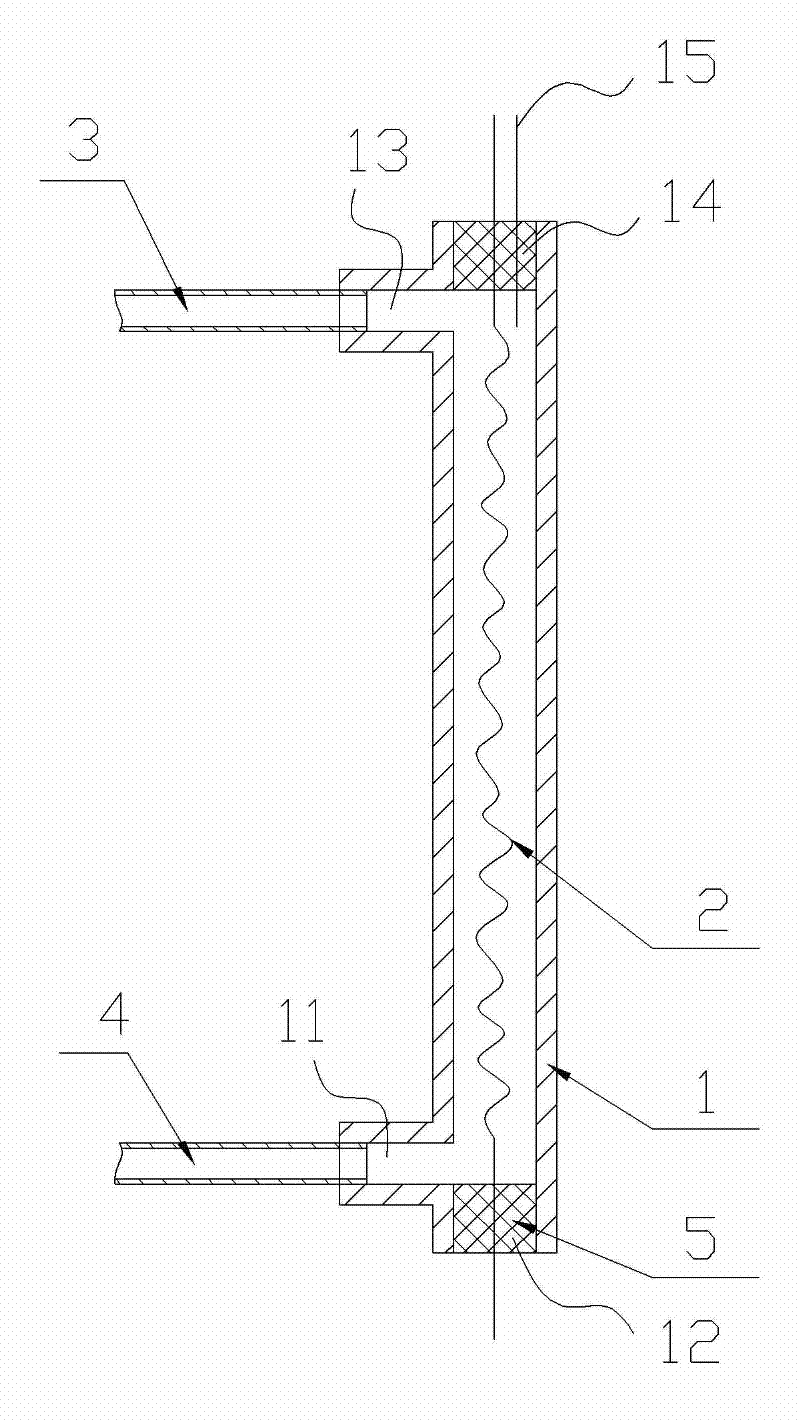

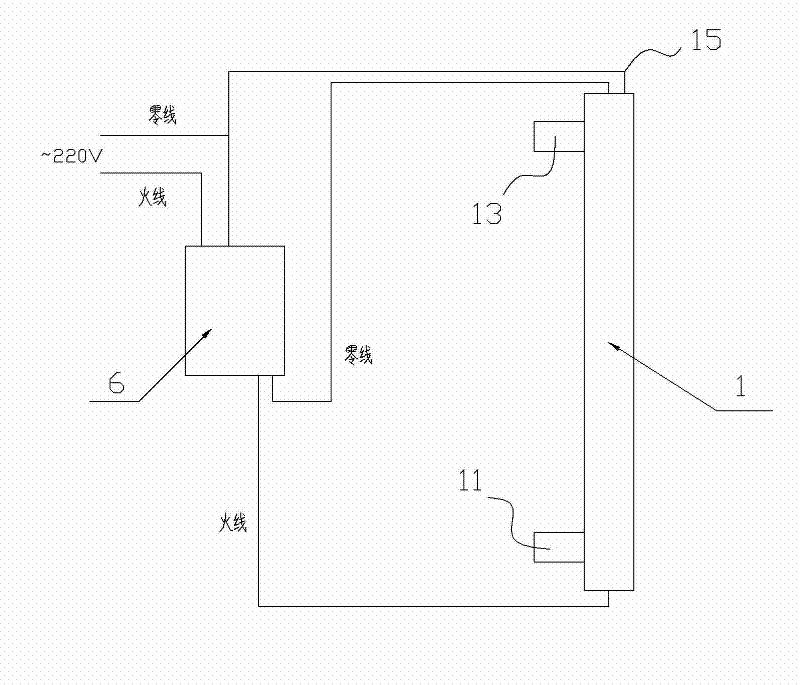

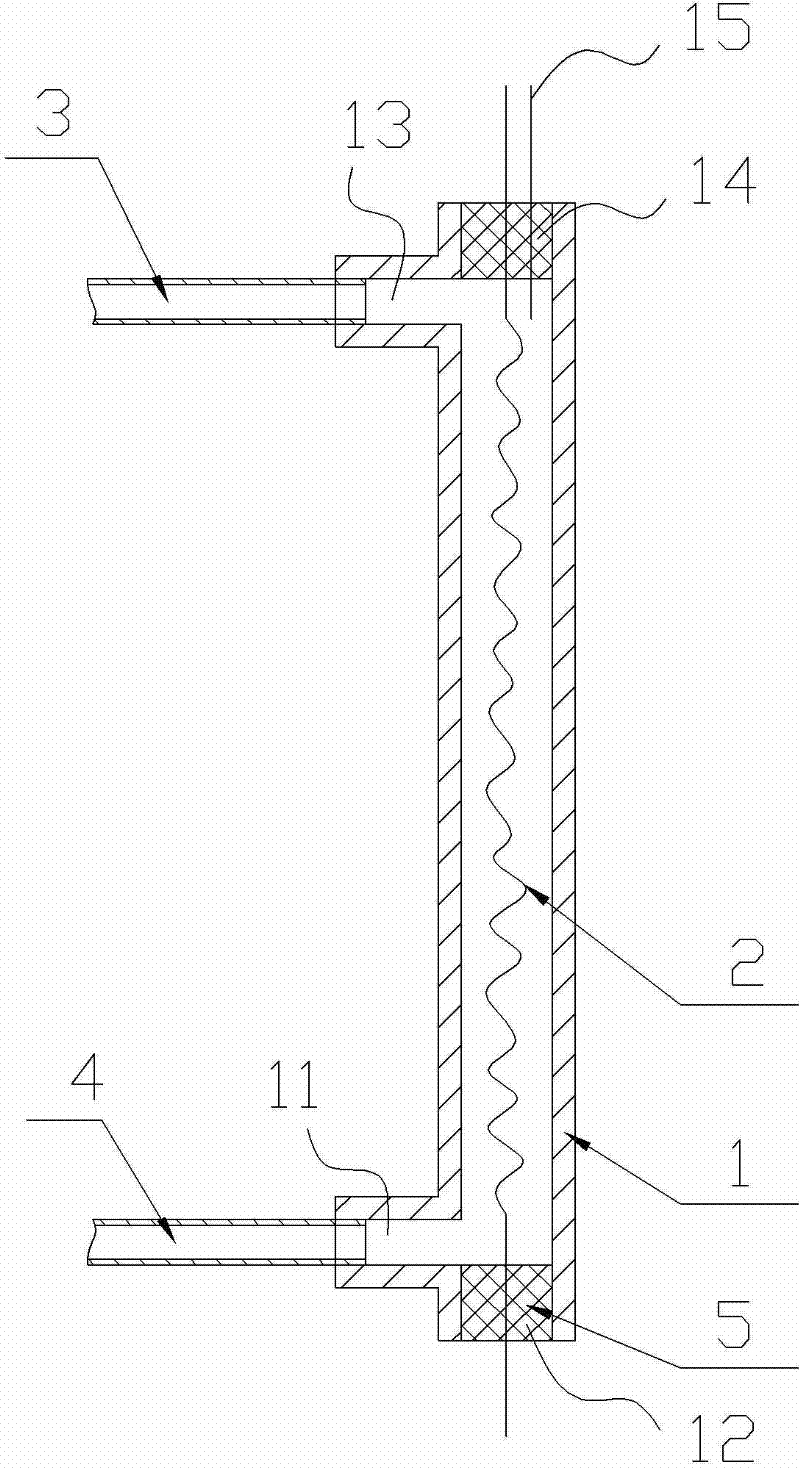

[0023] Such as figure 1 As shown, the present invention includes an insulating heating water pipe 1, a resistance wire 2, an insulating water outlet pipe 3, and an insulating water inlet pipe 4, wherein the insulating heating water pipe adopts a plastic pipe with a length of 1 meter and a diameter of 20 mm, and the resistance wire 2 is installed on the insulating heating water pipe. 1, its two ends are connected to the live wire and the neutral wire of the live wire connection port and the neutral wire connection port respectively, and the two ends are sealed with insulating filler. There is a water inlet 11 and a water outlet 13 on the insulated heating water pipe 1, wherein the water inlet 11 is close to the end of the live wire connection port, at the lower end of the insulated heating water pipe 1, and the water outlet 13 is close to the neutral wire connection port, at the upper end of the insulated heating water pipe 1, and the insulation inlet Water pipe 4 adopts a leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com