Preparation method of rich-theaflavin black tea

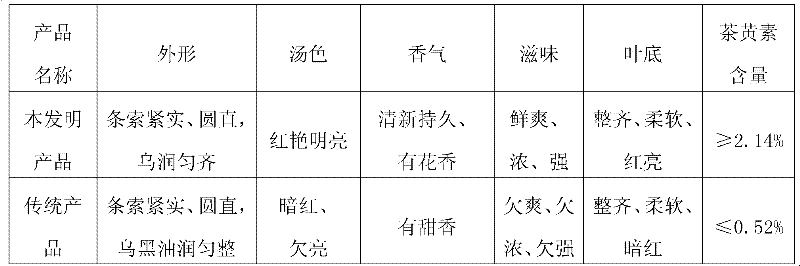

A technology of theaflavin black tea and fresh tea leaves, which is applied in tea treatment before extraction, can solve the problems of dark soup, low theaflavin content, and weak taste, and achieve the effect of improving the quality of finished tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The fresh leaves of Keemun tea with one bud and two leaves in summer are selected as raw materials.

[0025] The fresh tea leaves were withered by means of tank-type heating and withering, and the fresh tea leaves were evenly spread in the withering tank at a temperature of 28°C for 6 hours until the surface of the withered leaves lost luster and turned from bright green to dark green. The texture is soft, and the leaves are not easy to scatter when you let go of your hands. The tender stems are constantly broken. There are no withered buds, burnt edges, and red leaves. The green grass disappears, and it has a slight fragrance. When withering was completed, the water content of the blade was 64%; after the instant green tea was dissolved in 100 milliliters of water by the ratio of 1 gram of instant green tea, the instant green tea aqueous solution was evenly sprayed on the withered leaf in a ratio of 1:5 by weight, Mix well; knead the mixed withered leaves, deblock the ...

Embodiment 2

[0027] Choose spring one bud two leaves Zheng and Dabai tea fresh leaves as raw materials.

[0028] The fresh tea leaves are withered by heating and withering in a trough, and the fresh tea leaves are evenly spread in the withering trough at a temperature of 35°C for 4 hours until the surface of the withered leaves loses luster and turns from bright green to dark green. It is soft and lumpy, the leaves are not easy to scatter when you let go, the tender stems are broken and continuous, there are no withered buds, burnt edges, red leaves, etc., the grassy smell disappears, and it has a slight fragrance. When withering was completed, the water content of the blade was 58%; after the instant green tea was dissolved in 500 milliliters of water by the ratio of 1 gram of instant green tea, the instant green tea aqueous solution was evenly sprayed on the withered leaves in a ratio of 1:15 by weight, Mix well; knead the mixed withered leaves, deblock the kneaded leaves with a three-me...

Embodiment 3

[0030] Choose one bud and two leaves in autumn and the fresh leaves of Dabai tea as raw materials.

[0031] The fresh tea leaves are withered in a tank-type heating and withering method, and the fresh tea leaves are evenly spread in the withering tank at a temperature of 32°C for 5 hours until the surface of the withered leaves loses luster and turns from bright green to dark green. It is soft and lumpy, the leaves are not easy to scatter when you let go, the tender stems are broken and continuous, there are no withered buds, burnt edges, red leaves, etc., the grassy smell disappears, and it has a slight fragrance. When the withering was completed, the water content of the leaves was 62%; after the instant green tea was dissolved in water at a ratio of 1 gram of instant green tea to 300 milliliters of water, the instant green tea aqueous solution was evenly sprayed on the withered leaves in a ratio of 1:10 by weight, Mix well; knead the mixed withered leaves, deblock the knead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com