Method for debugging oxygen-rich gas adjustment system and putting it into operation

A regulation system and oxygen enrichment technology, applied in control/regulation system, blast furnace details, blast furnace, etc., can solve problems such as affecting blast furnace production, poor stability of oxygen content, and hidden dangers in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

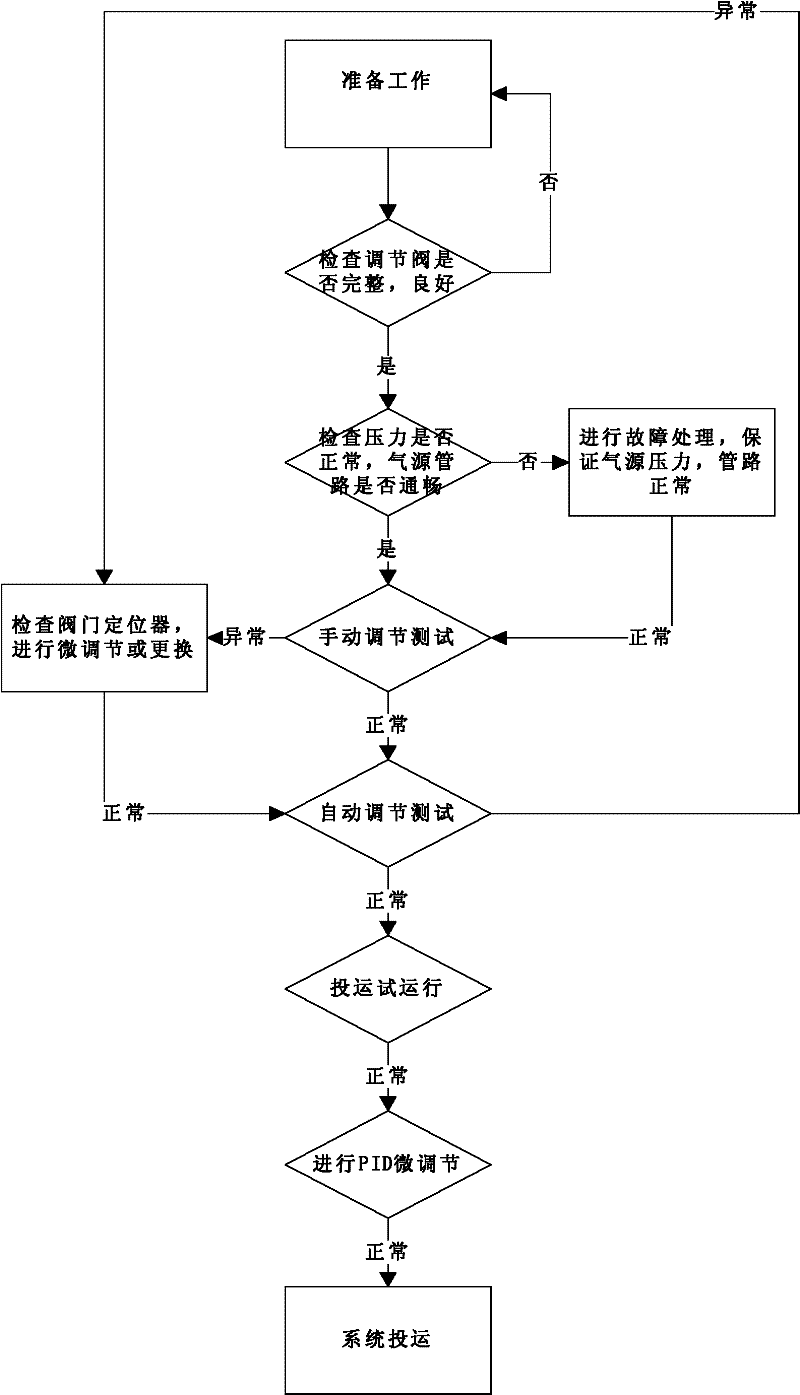

[0024] image 3 It is a specific implementation of the PID regulation and operation method. First, make preparations for the equipment, check the integrity of the regulating valve, the smoothness of the gas source pipeline, and the correct selection of the gas source. When the preparations are completed, Manually adjust the regulating valve. The normality of the manual adjustment not only ensures the normal stability of the equipment, but then performs automatic adjustment, and uses the micro-adjustment system to ensure the stability of the automatic adjustment.

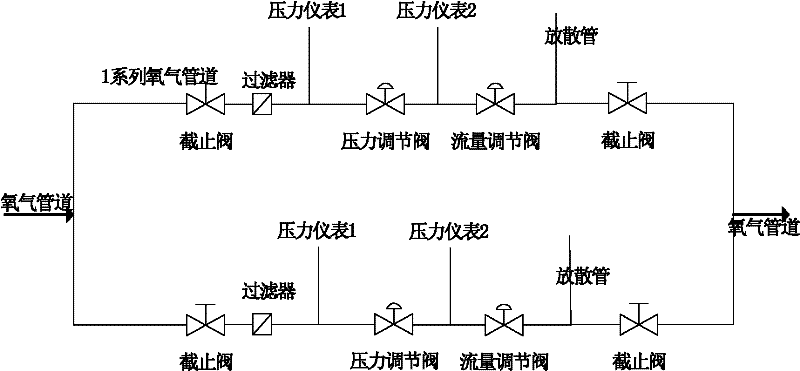

[0025] (1) First confirm the operation of the two-way redundant system and ensure the oxygen-enriched pressure. The flow pneumatic membrane regulating valve is installed in the explosion-proof wall, and nitrogen is used as the working gas source of the regulating valve; the temperature is low in winter, and nitrogen is not used as the gas source. The phenomenon of air source freezing will occur, so as to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com