Griffe transmission mechanism of electronic jacquard machine

An electronic jacquard, transmission mechanism technology, applied in the direction of jacquard, textile, textile and paper making, etc., can solve the problem of complex structure of the transmission mechanism, and achieve the effects of stable operation, ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

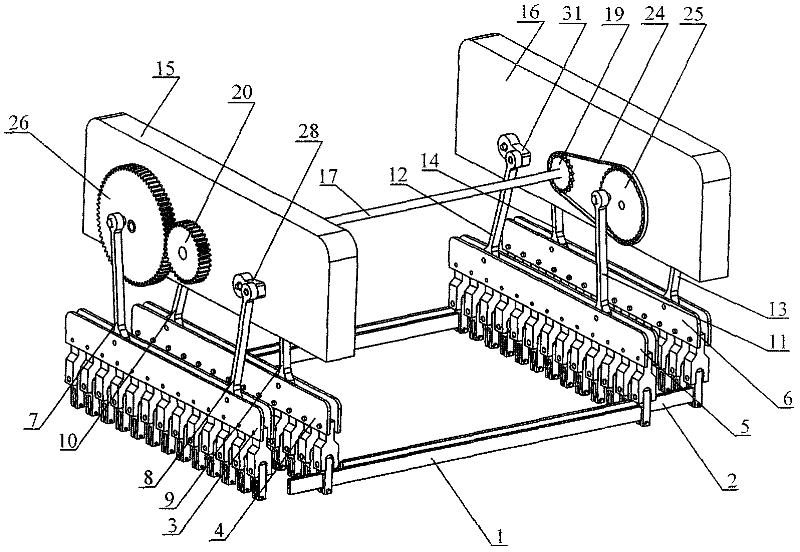

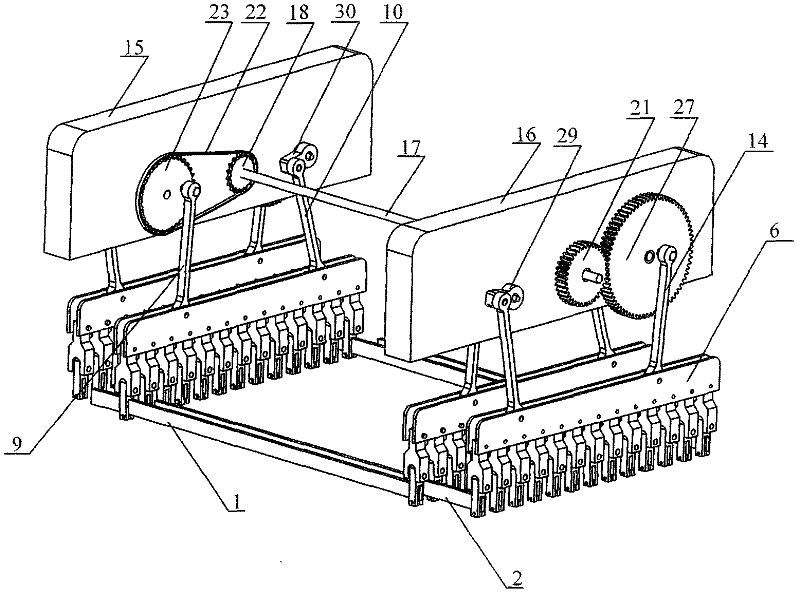

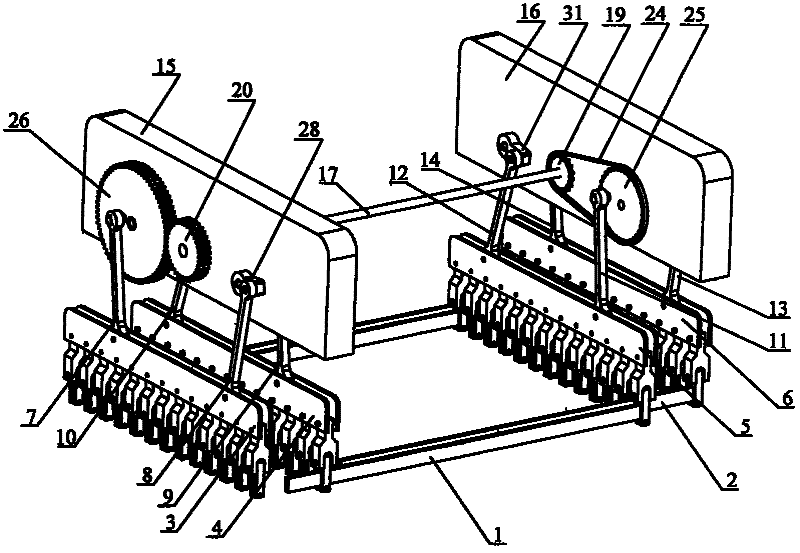

[0015] The structure and working principle of the electronic jacquard knife girder drive of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] like figure 1 , figure 2 As shown, a kind of lifting mechanism of electronic jacquard machine includes the lifting knife at the lower end of the frame, that is, the first lifting knife 1 and the second lifting knife 2; four lifting arms for lifting the lifting knife on both sides of the frame, namely Left outer needle lifting arm 3 , left inner needle lifting arm 4 , right inner needle lifting arm 5 and right outer needle lifting arm 6 .

[0017] 8 connecting rods connecting the needle lifting arm, that is, the first connecting rod 7, the second connecting rod 8, the third connecting rod 9, the fourth connecting rod 10, the fifth connecting rod 11, the sixth connecting rod 12, the seventh connecting rod Rod 13 and eighth connecting rod 14.

[0018] By the fixed plates on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com