Compact single-suction centrifugal fan

A centrifugal fan, single-suction technology, applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problem of excessive axial size of the casing, increased bending stress of blades, and difficulty in meeting the requirements of high-quality carbon steel and other issues to achieve the effect of improving operating efficiency, improving flow field and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

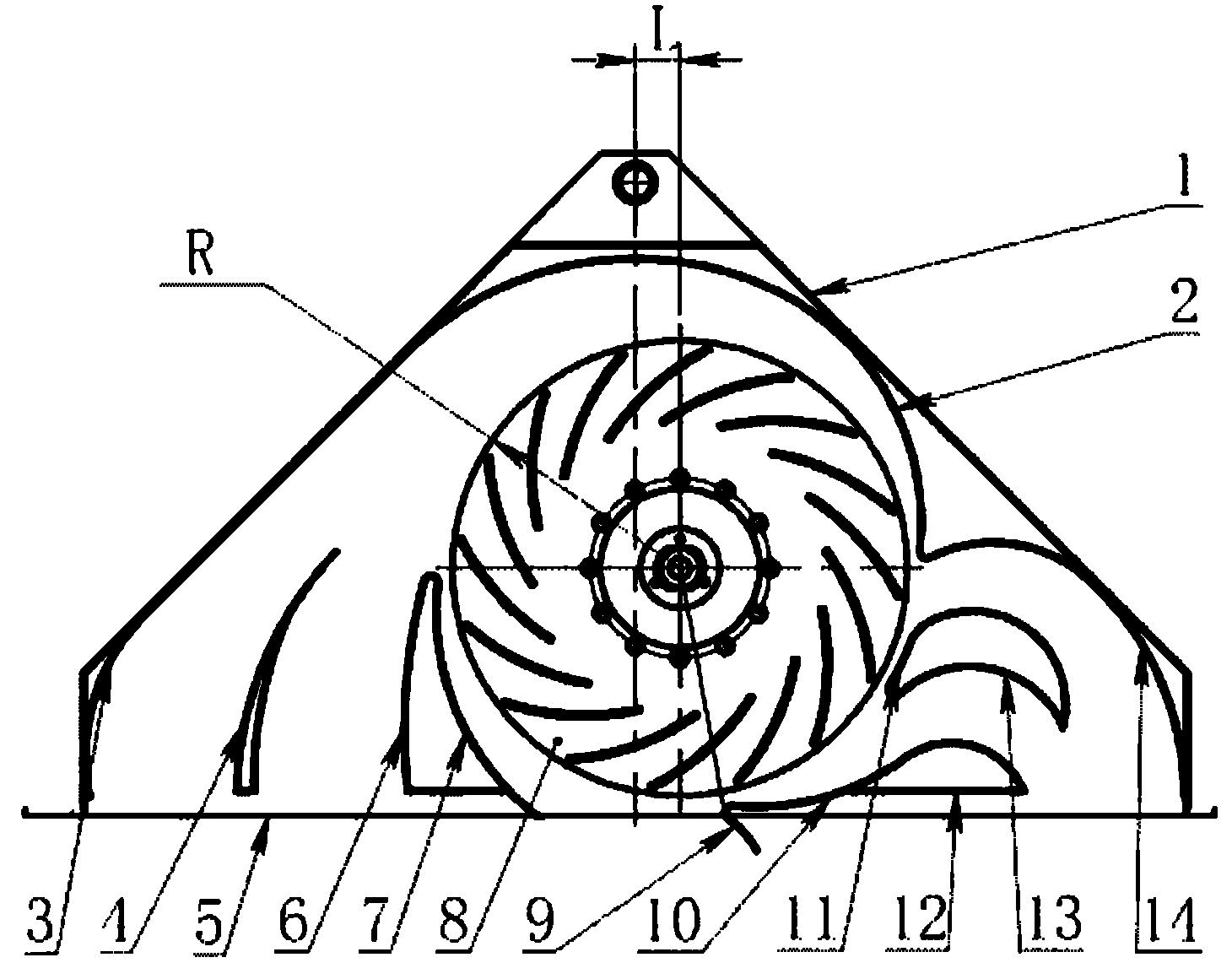

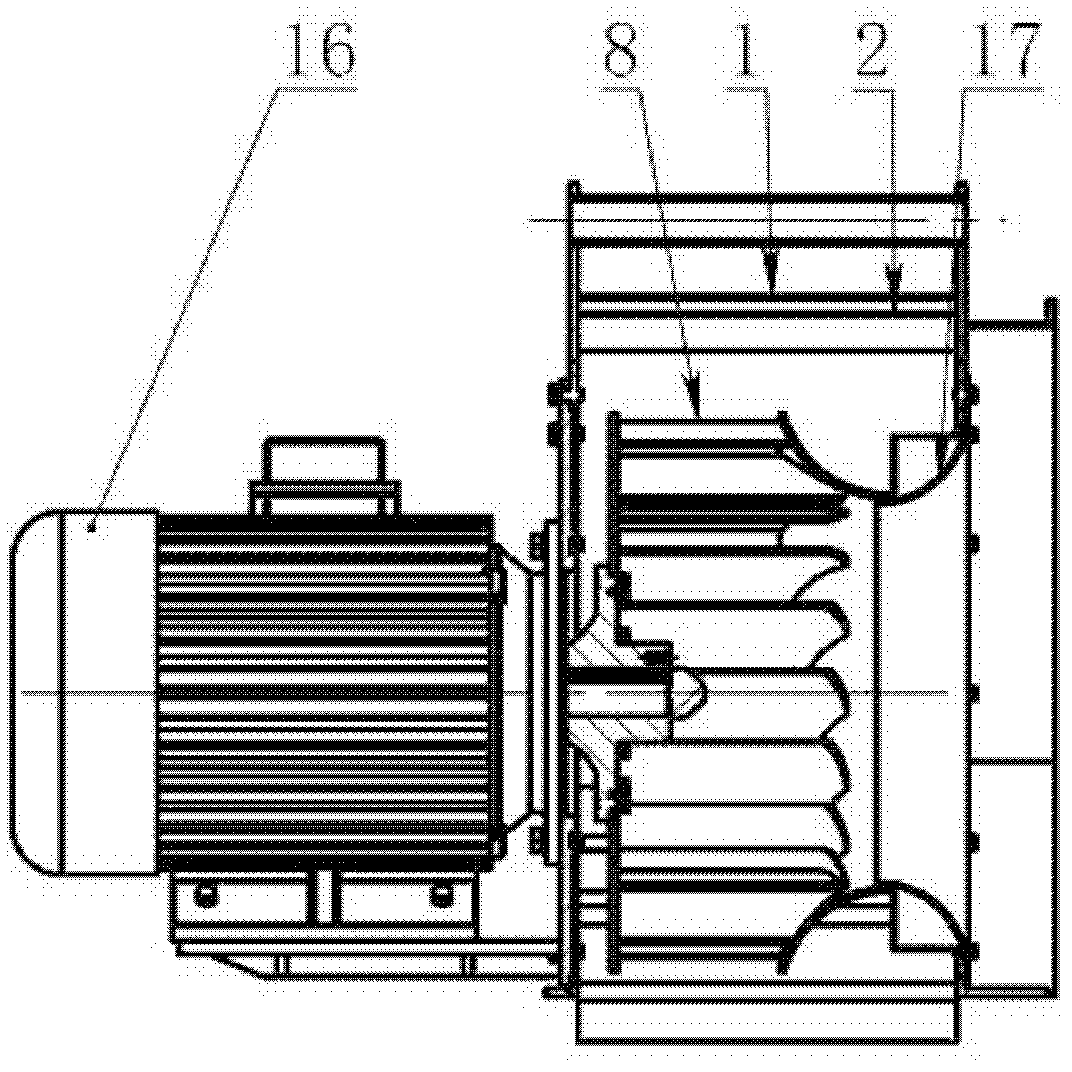

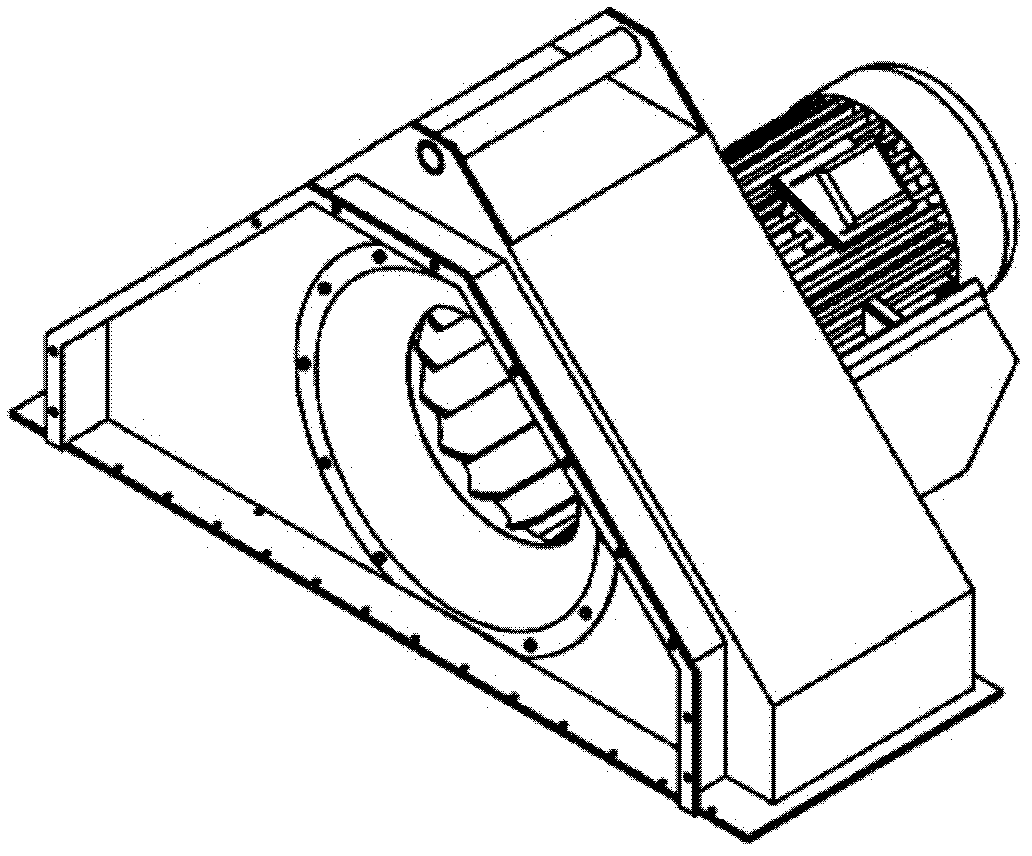

[0023] figure 1 It is a structural schematic diagram of an embodiment of the centrifugal fan of the present invention. like figure 1 As shown, the casing of the ventilator can only be designed as a triangle according to the site conditions, and a centrifugal impeller 8 is built in the triangular cavity 1, and the vertical centerline of the impeller 8 is offset to the right. The distance between the plane of symmetry) is L, and the value of L is 0.18-0.22R, where R is the radius of the impeller.

[0024] Around the rotation center of the impeller 8, four sections of half-volutes with different lengths are distributed sequentially, and the profiles of the four sections of half-volutes with different lengths are all logarithmic spirals. Among them, the starting point of the volute tongue of the first half volute 2 starts from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com