Inspection method for microcracks at corner of carbon steel continuous casting blank

An inspection method and continuous casting slab technology, which is applied in the preparation of test samples, sampling devices, and optical testing for flaws/defects, etc., can solve problems such as scrap products after rolling, achieve the effect of improving the process and eliminating the corner defects of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] It is implemented on a billet with a thickness of 230mm and a width of 1700mm, and the steel type is SN400B.

[0028] (1) Sampling

[0029] After the pouring conditions are stable, reserve a sample at the end of the second slab of the third furnace for continuous casting in the tundish, and check the quality of the corner of the slab under the current continuous casting process to determine whether the current continuous casting process meets the steel grade requirements.

[0030] (2) Sample cutting

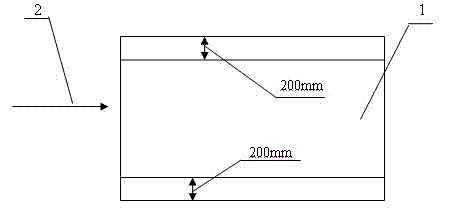

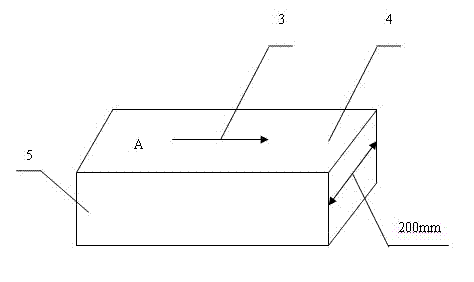

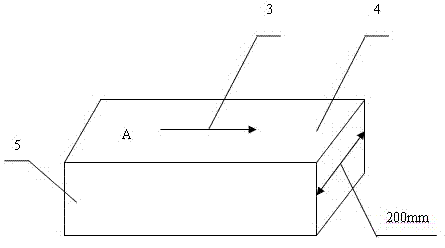

[0031] After the slab is off-line, the sample is cut off the slab offline, and the sample strips are cut on both sides of the sample. The cutting position of the sample strips is as follows: figure 1 ;

[0032] When cutting the sample strip, it is required that the cutting surface is flat, and the unevenness, inclination, and bow shape of the cutting section should not exceed 10-15mm, and oxygen burning pits should not appear.

[0033] (3) The label of the sample strip,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com