A method for detect welding quality of component arc weld

A technology of welding quality and detection method, applied in the field of welding quality detection of component arc welding, can solve the problems of large time consumption, labor force, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

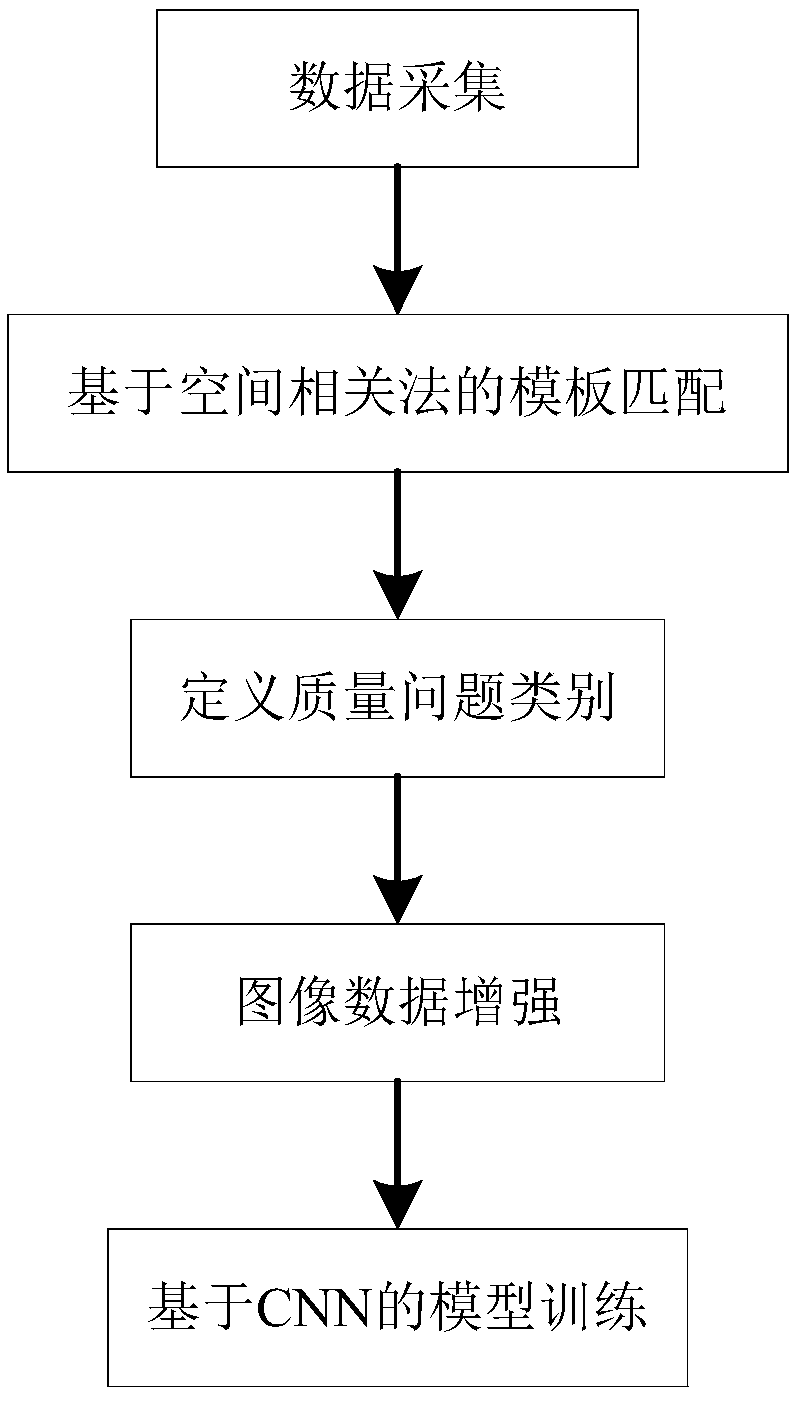

[0043] A component arc welding welding quality detection method, comprising the following steps:

[0044] S1 uses the camera to shoot, collect a certain number of pictures of different types of welding heads of the same component arc welding, and establish a sample library. The samples in the sample library are divided into two parts, one part is used as the training set, and the training set is used to train the machine learning classifier. The other part is used as a test set, which is used to identify its corresponding welding quality type. For example, 70% of the samples in the sample library are used as the training set, and 30% of the samples are used as the test set.

[0045] In order to make the convolutional neural network more efficient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com