Molded part conveying mechanism and molded part separation device using same

A conveying mechanism and bone separation technology, which is applied in the field of material and bone separation device and material and bone conveying mechanism, can solve the problems of high process conditions and complex structure, and achieve the effects of high surface quality, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

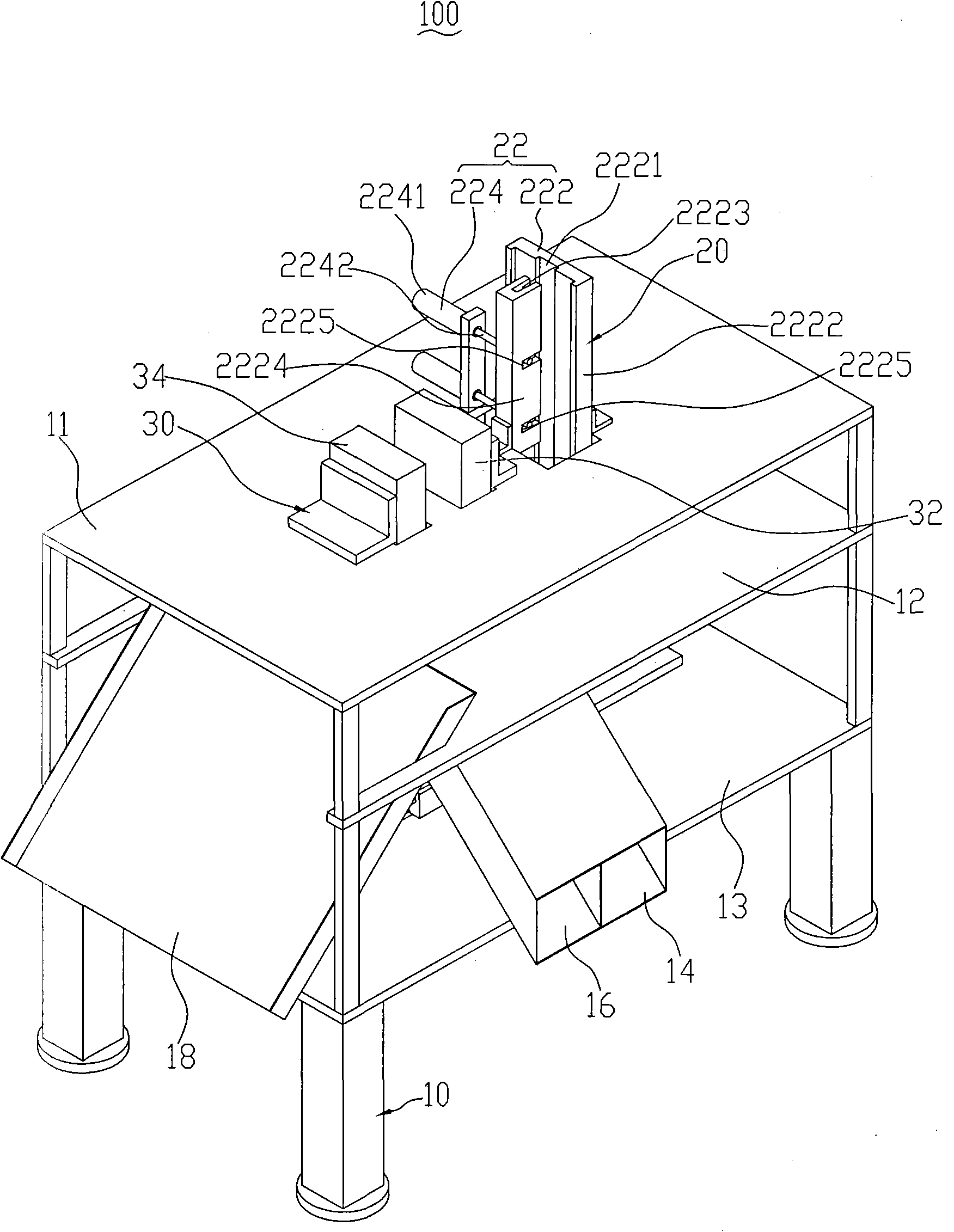

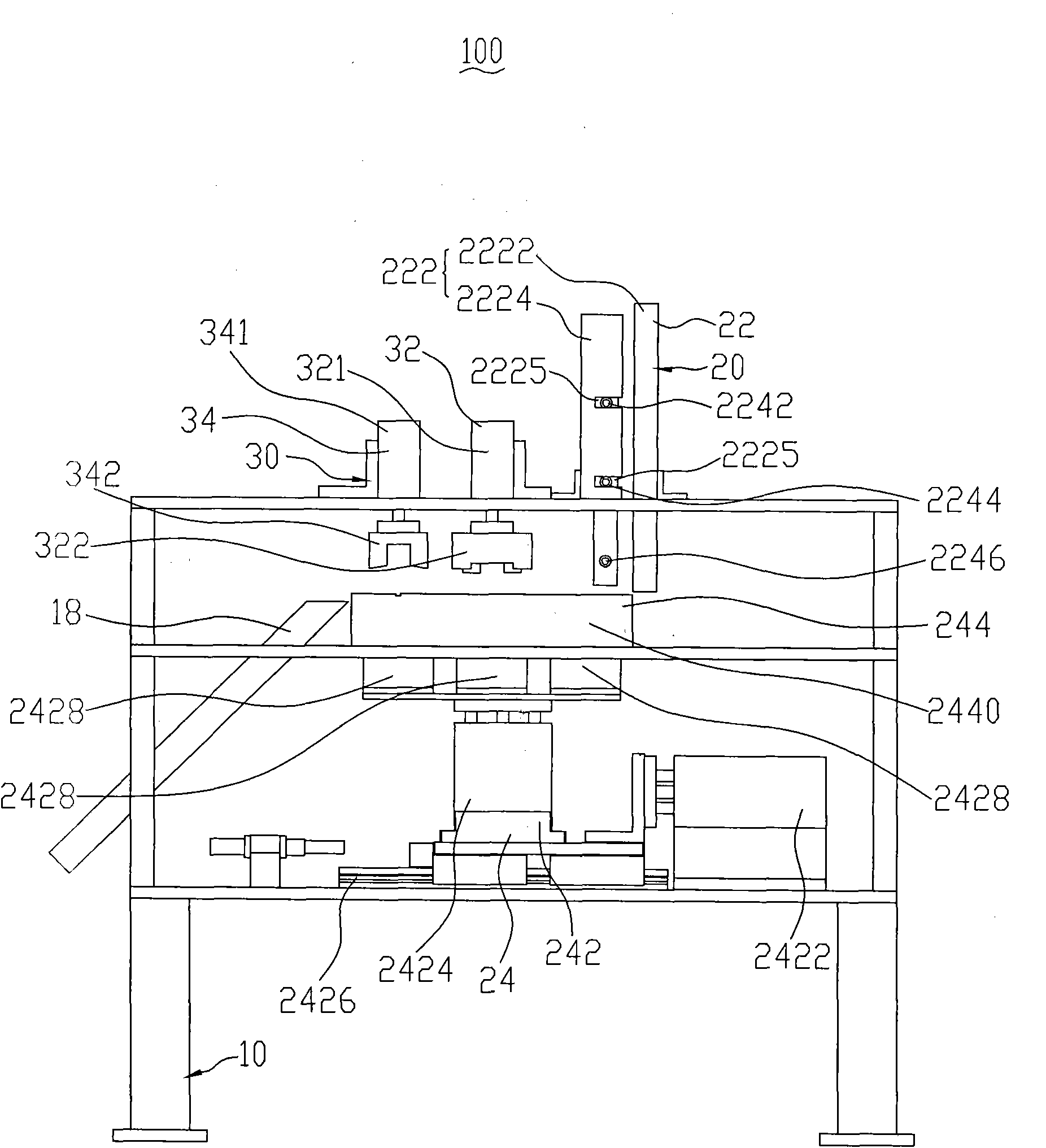

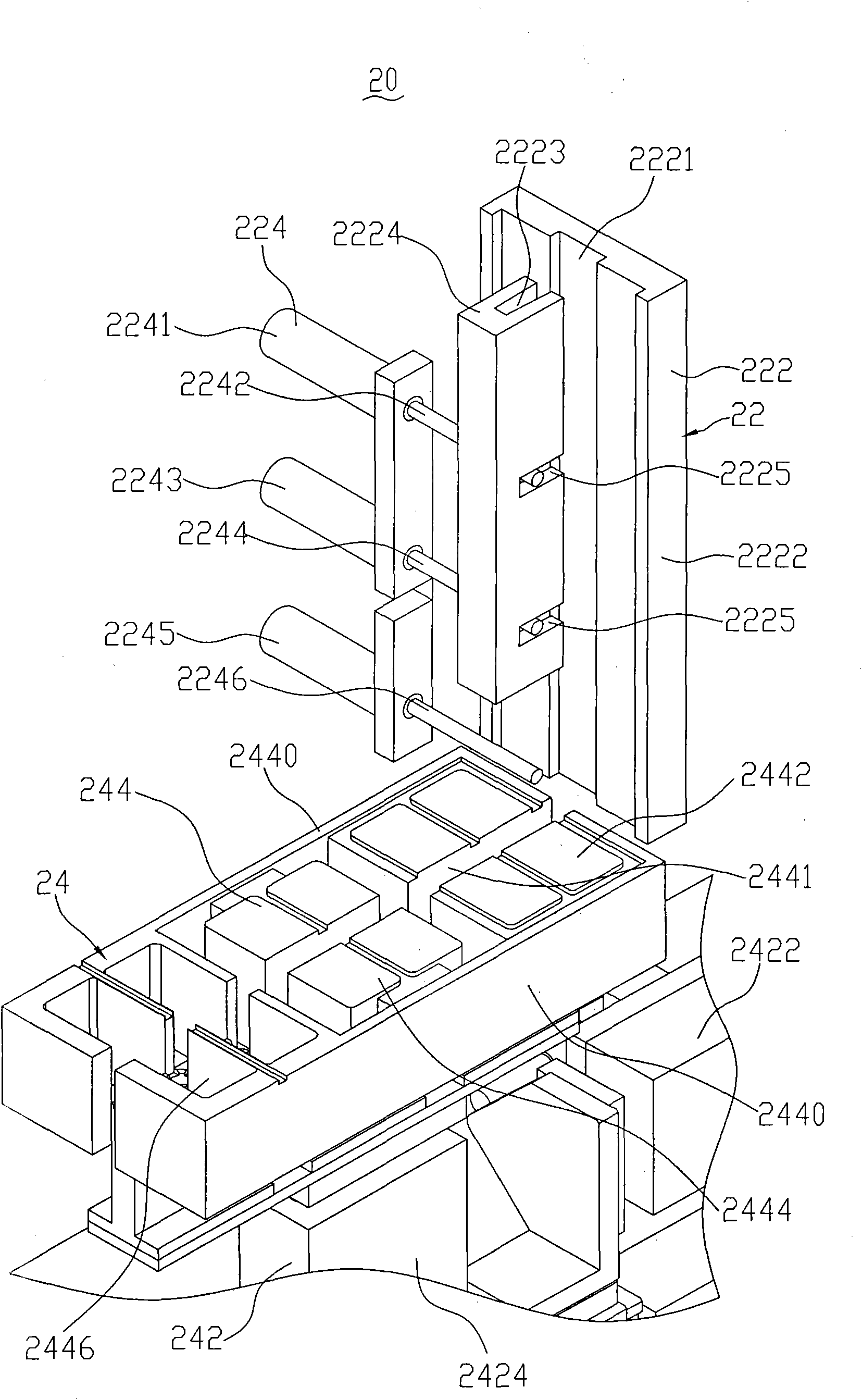

[0054] Please refer to figure 1 , the bone separating device 100 includes a frame 10, a bone conveying mechanism 20, a bone separating mechanism 30 and a control system (not shown). This bone separating device 100 is used for a pull-tab die casting 40 (such as Figure 8 shown) for material bone separation. The pull tab die-casting 40 includes a main rib 42 , a primary rib 41 , a plurality of pull tabs 44 and a pair of handles 46 . The aggregate conveying mechanism 20 and the aggregate separating mechanism 30 are respectively fixed on the frame 10 . The frame 10 is formed by a plurality of columns supporting a square table 11 , a table 12 and a table 13 . The frame 10 includes a handle collection tube 14 , a tab collection tube 16 and a bone collection tube 18 . The material bone collection cylinder 18 is positioned at the front end of the conveying mechanism 20 (such as figure 2 As shown), the handle collection tube 14 and the tab collection tube 16 are located on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com