Lateral force resisting method for soft soil foundation building

A technology for soft soil foundations and buildings, applied in the fields of geotechnical engineering and construction engineering, can solve problems such as damage, insufficient strength, and inability to be widely used in industrial and civil buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

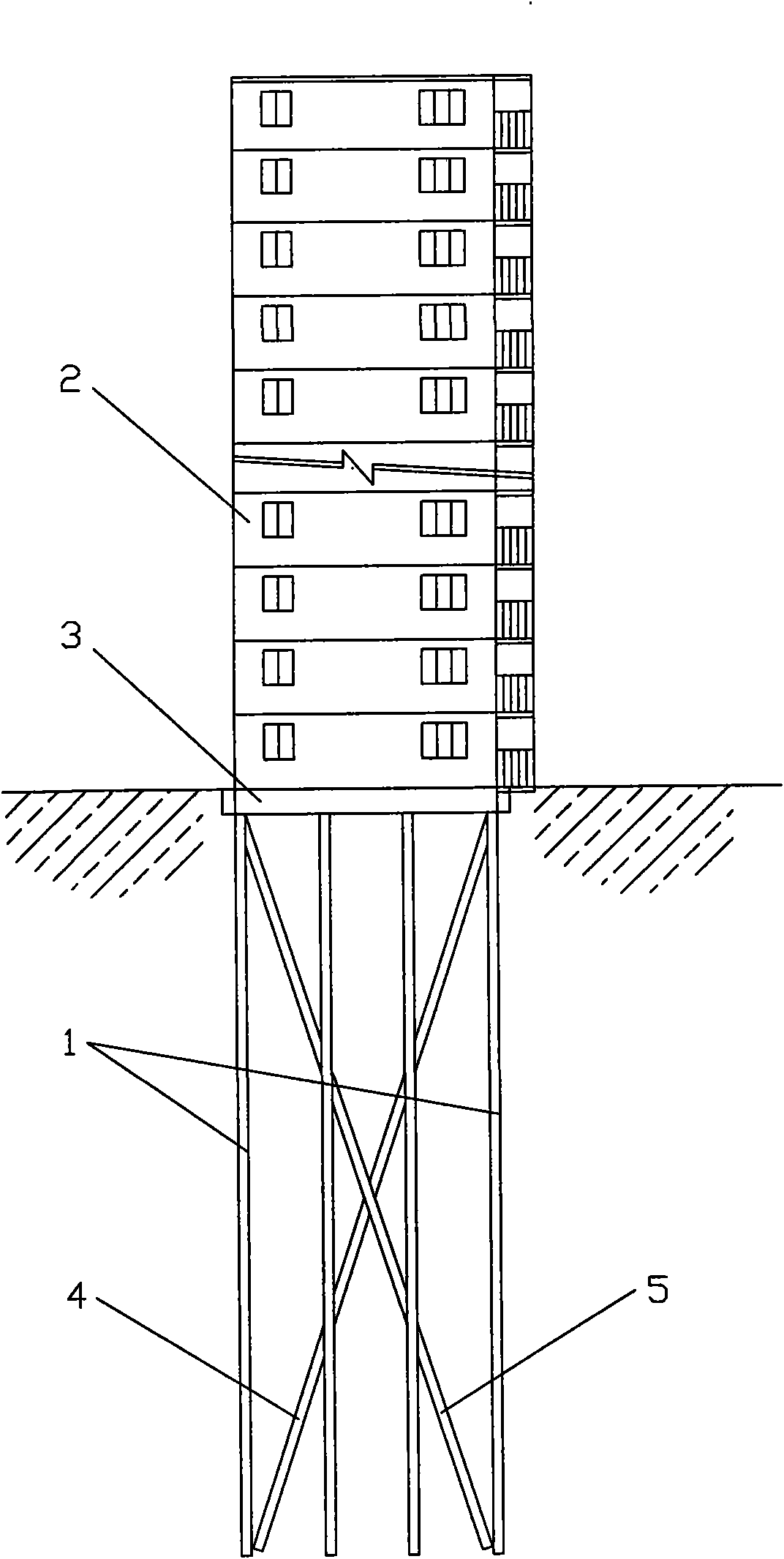

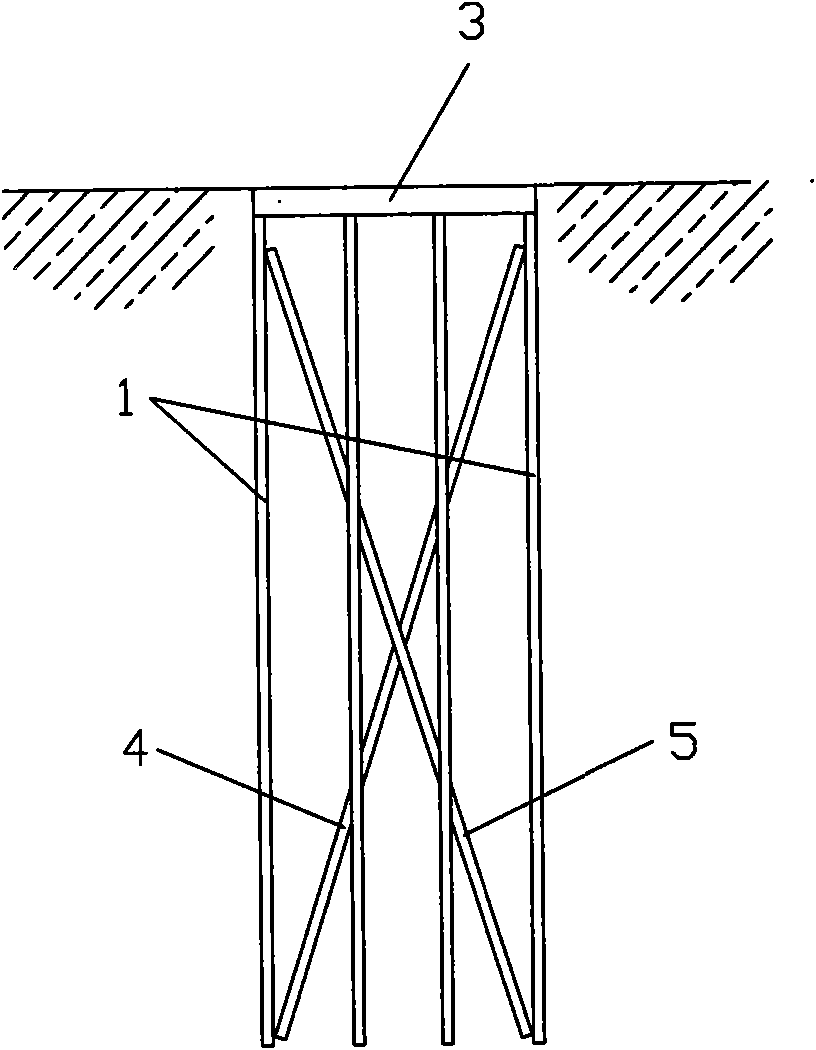

[0038] see Figure 2a ~ Figure 2c , the method of the present invention is used for newly-built building to set up inclined pile.

[0039] 1) Construct the straight pile 1 and the inclined pile 4, 5 with a depth of about 30m at the position of the new building 2 with a width of about 10m;

[0040] 2) The top of the inclined piles 4 and 5 is arranged on one side of the outer contour of the building 2, and the bottom thereof is arranged on the other side of the outer contour of the building 2, so that the inclined piles 4 and 5 can be arranged within the permitted building plane range; 4.5 Steel pipe members poured into concrete are used, the top of which can withstand both pressure and tension, and the tensile strength per unit cross-sectional area is greater than 5Mpa;

[0041] 3) Build the building foundation 3 on the straight pile 1, and the form of the building foundation 3 can be a strip shape, a raft shape or a box shape; the inclined piles 4, 5 are disconnected from the...

Embodiment 2

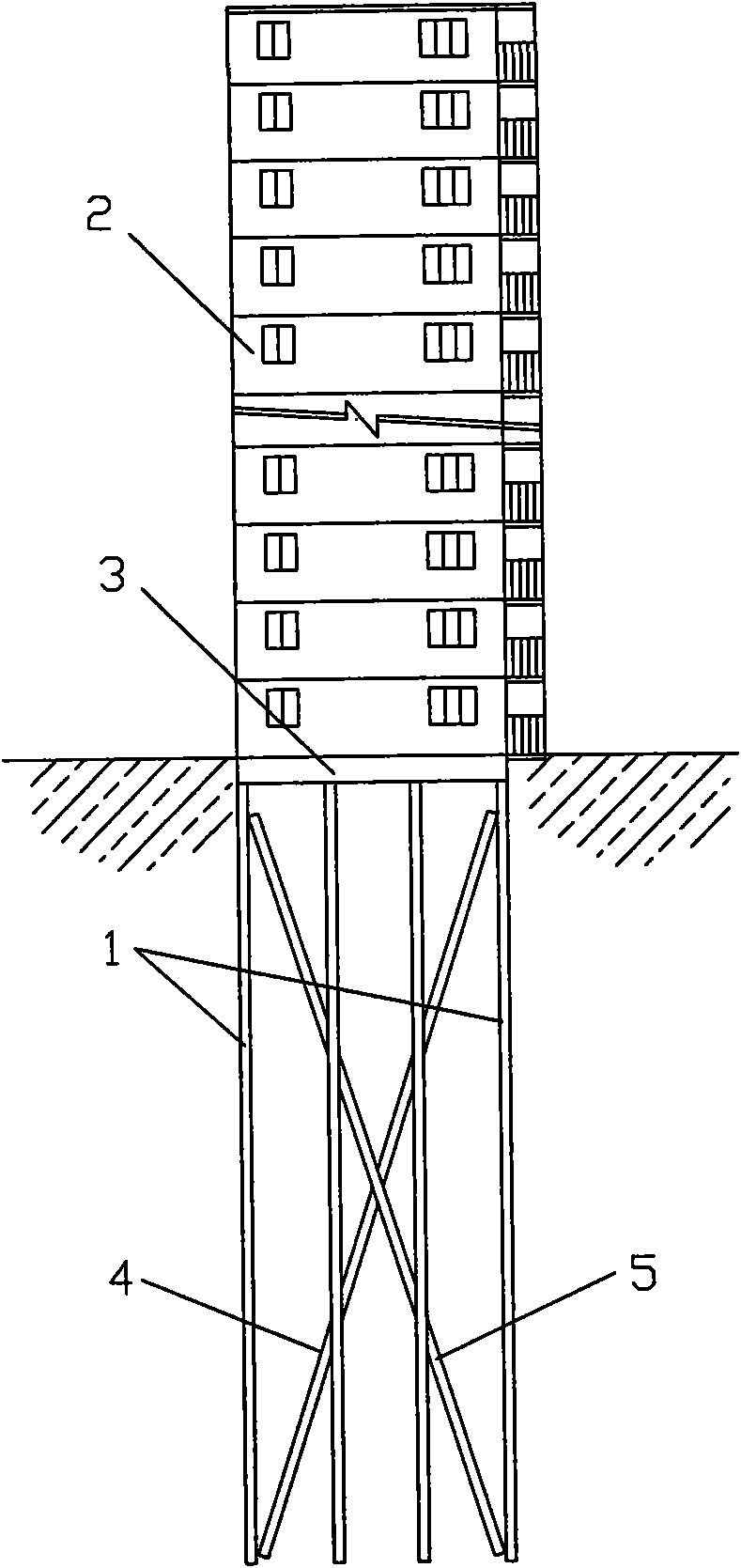

[0045] see Figure 3a ~ Figure 3c , the method of the present invention is used for adding inclined piles to existing buildings.

[0046] 1) Under the built building 2 with a width of about 10m, a building foundation 3 and a straight pile 1 with a depth of about 30m are arranged, and the form of the foundation 3 can be strip-shaped, raft-shaped or box-shaped;

[0047] 2) After the construction of the building 2 is completed and the settlement is stable, the inclined piles 4 and 5 with a depth of about 30m are sunk under the building foundation 3;

[0048]3) The top of the inclined piles 4 and 5 is arranged on one side of the outer contour of the building 2, and the bottom thereof is arranged on the other side of the outer contour of the building 2, so that the inclined piles 4 and 5 can be arranged within the permitted building plane range; 4.5 Steel pipe members poured into concrete are used, the top of which can withstand both pressure and tension;

[0049] 4) The tops of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap