Wireless monitoring fully mechanized mining hydraulic support

A hydraulic support and wireless monitoring technology, applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., can solve the problems of roof beam collapse, pillar collapse, waste of time and energy, etc., to achieve fast remote detection and prolong service life , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The relevant technical contents not mentioned below can adopt or learn from the prior art.

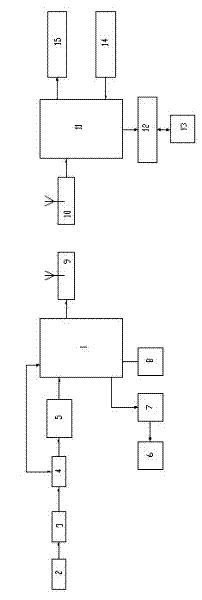

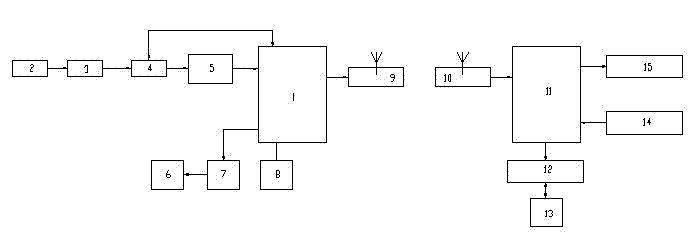

[0026] Such as figure 1 As shown, a wireless monitoring fully mechanized mining hydraulic support includes a first processing circuit, and the first processing circuit includes a first processor 1. This processor adopts a single-chip microcomputer model 89C52, and is connected with the first processor 1. A multi-channel parallel pressure data monitoring circuit, the pressure data monitoring circuit includes a pressure sensor 2 connected in sequence, a signal conditioning circuit 3, a signal amplification circuit 4 and a conversion circuit 5, and the conversion circuit 5 is an A / D conversion The model of the circuit is 7135, and the output end of the conversion circuit 5 is connected to the first processor 1.

[0027] A solenoid valve 6 is connected to the first processor 1 , and the solenoid valve 6 is a pilot electro-hydraulic control valve, which is connected to the first pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com