Counterforce offsetting device and pasting machine having the device

A reaction force, gluing machine technology, used in metal processing equipment, coatings, manufacturing tools, etc., can solve problems such as impossibility, complex structure and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

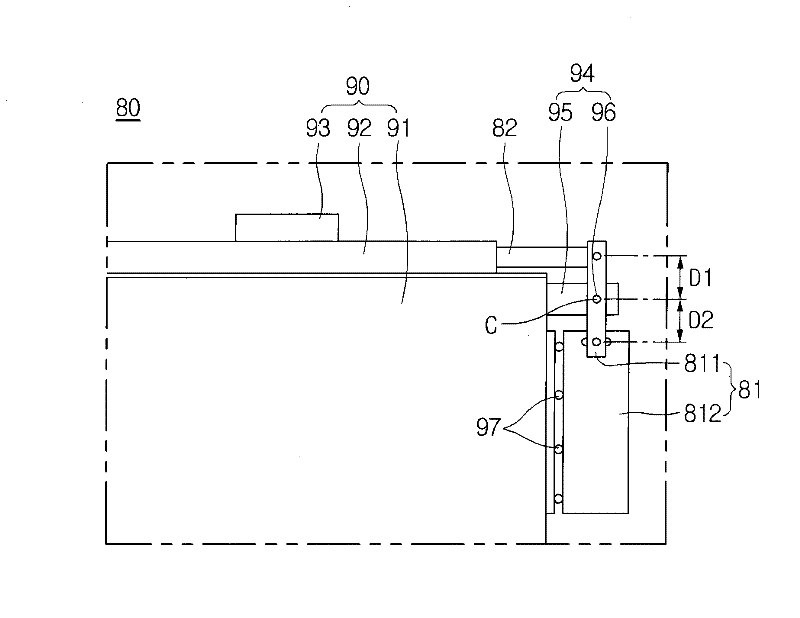

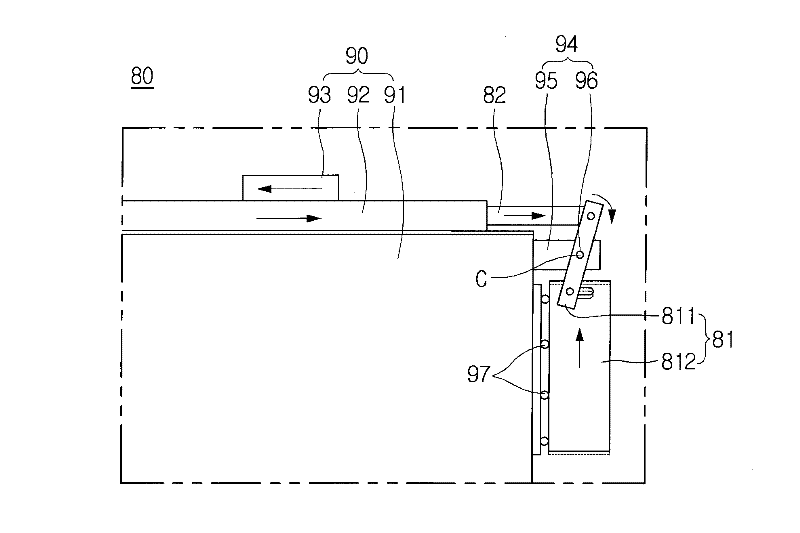

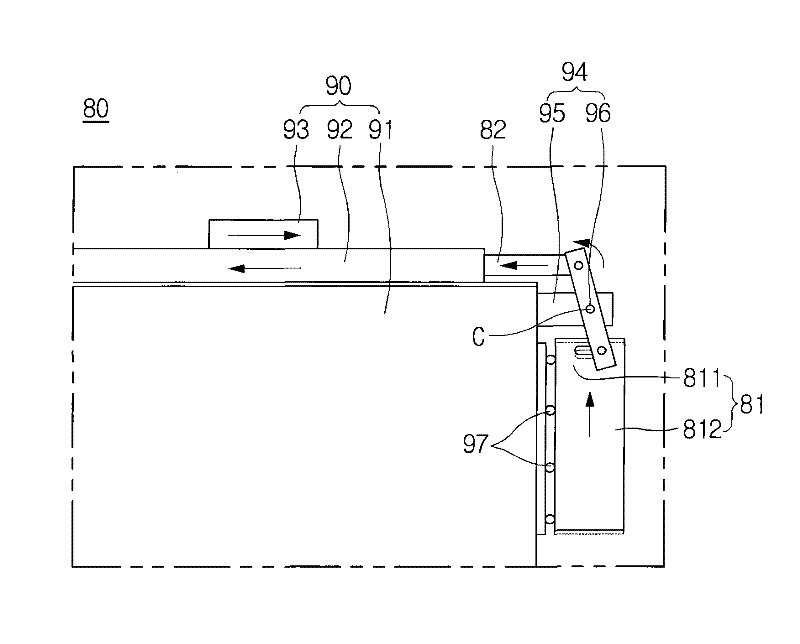

[0034] Hereinafter, a reaction force canceling device according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

[0035] Such as Figures 1 to 3 As shown in , the reaction force canceling device 80 according to the first embodiment of the present invention may include a reaction force canceling unit 81 installed on the conveying system 90 to thereby cancel the reaction force generated by the movement of the moving element 93, wherein the The transport system 90 is movably mounted with moving elements 93 for the intended purpose. Here, the transfer system 90 may include a supporting member 92 movably supporting a moving member 93 and a frame 91 slidably supporting the supporting member 92 . The moving element 93 is supported by the supporting element 92 such that it can move in the longitudinal direction of the supporting element 92 . The supporting member 92 can be moved in the longitudinal direction of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com