Guide sleeve of forging press

A technology of guide sleeve and forging press, applied in the field of guide sleeve, can solve the problems of large wear of guide sleeve, decreased guiding effect, unstable structure, etc., and achieves the effects of stable operation of equipment, reduction of force and friction, and improvement of utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

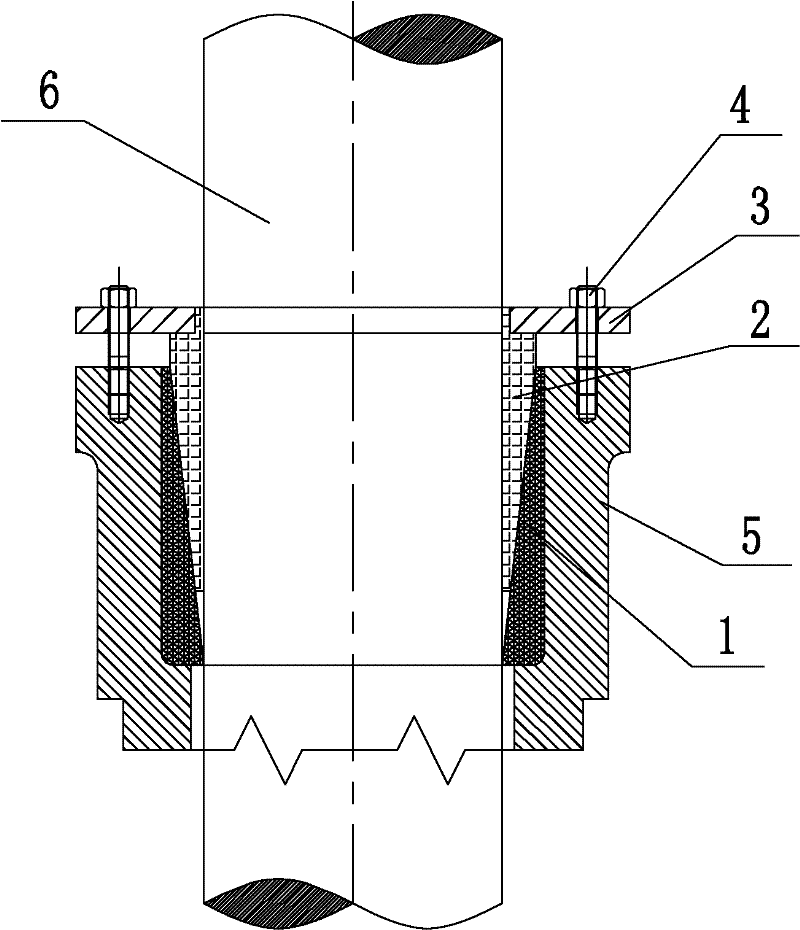

[0022] see figure 1 , the adjustable guide sleeve of the present invention includes a fixed guide sleeve 1, a movable guide sleeve 2, a pressure plate 3 and a compression bolt 4, wherein the fixed guide sleeve 1 is fixed between the mounting bracket 5 and the column 6 to ensure that the outer surface and The mounting bracket 5 is closely matched, and the movable guide sleeve 2 is pressed between the fixed guide sleeve 1 and the column 6 with the pressure plate 3, so that the column 6 will not shake, and the pressure plate 3 and the mounting bracket 5 are fastened with the compression bolt 4, and the pressure plate The material is during production, because the column 6 will be subjected to a large stress brought by the plunger, and the inner surface of the movable guide sleeve 2 will be worn to a certain extent. 2. Press into the movable gap between the fixed guide sleeve 1 and the column 6. According to production experience, the press-in value of the adjustable guide sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com