Novel friction type clutch brake mechanism of steel plate shearer

A clutch brake, shearing machine technology, applied in the combination of couplings and brakes, shearing devices, mechanical equipment, etc., can solve the problems of production shutdown and maintenance, consumption of manpower, material resources, financial resources, and prone to broken teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is a clutch brake mechanism containing two friction plates. The purpose of disclosing the present invention is to protect all improvements within the scope of the present invention, and the present invention is not limited to the following embodiments.

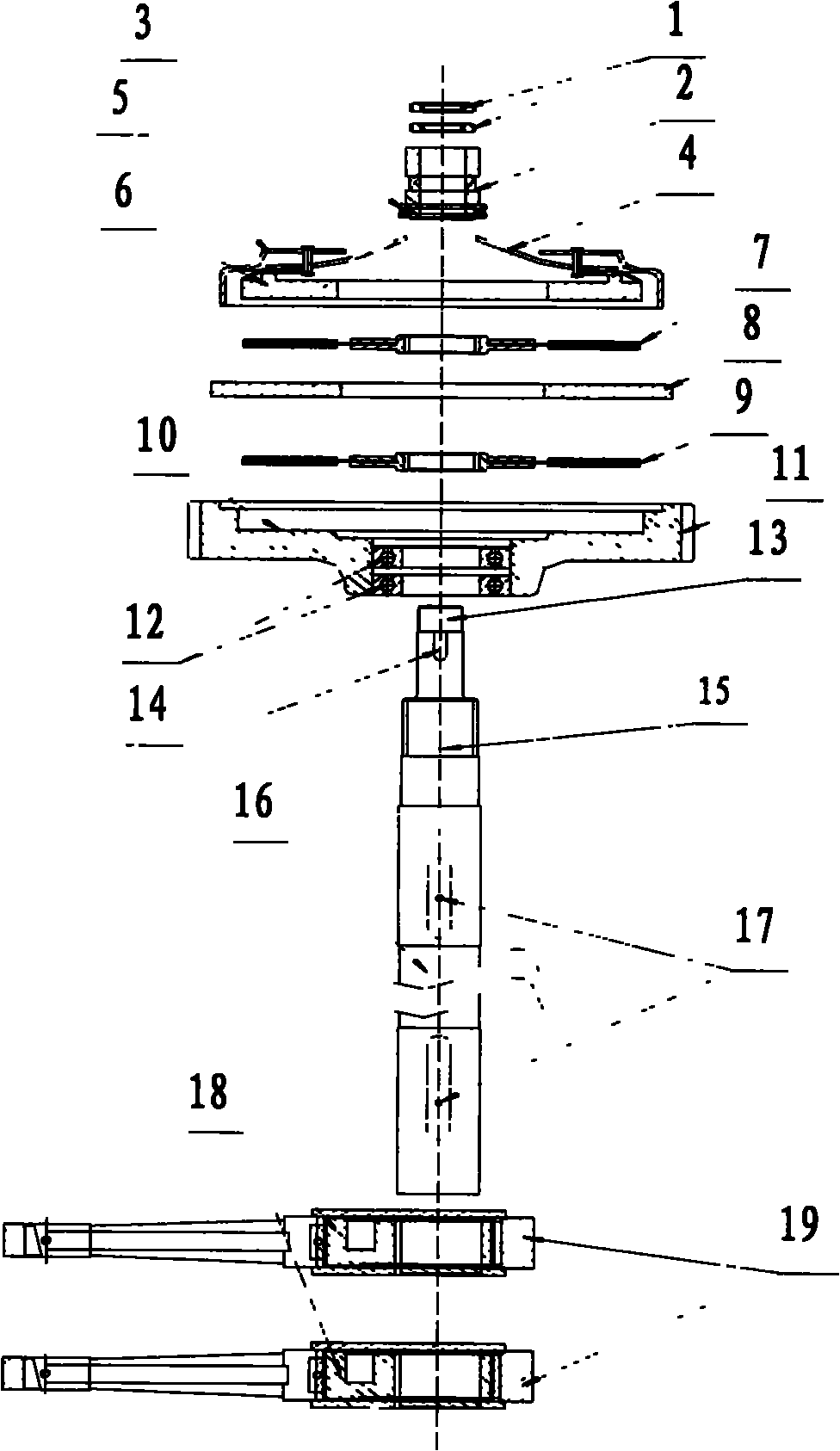

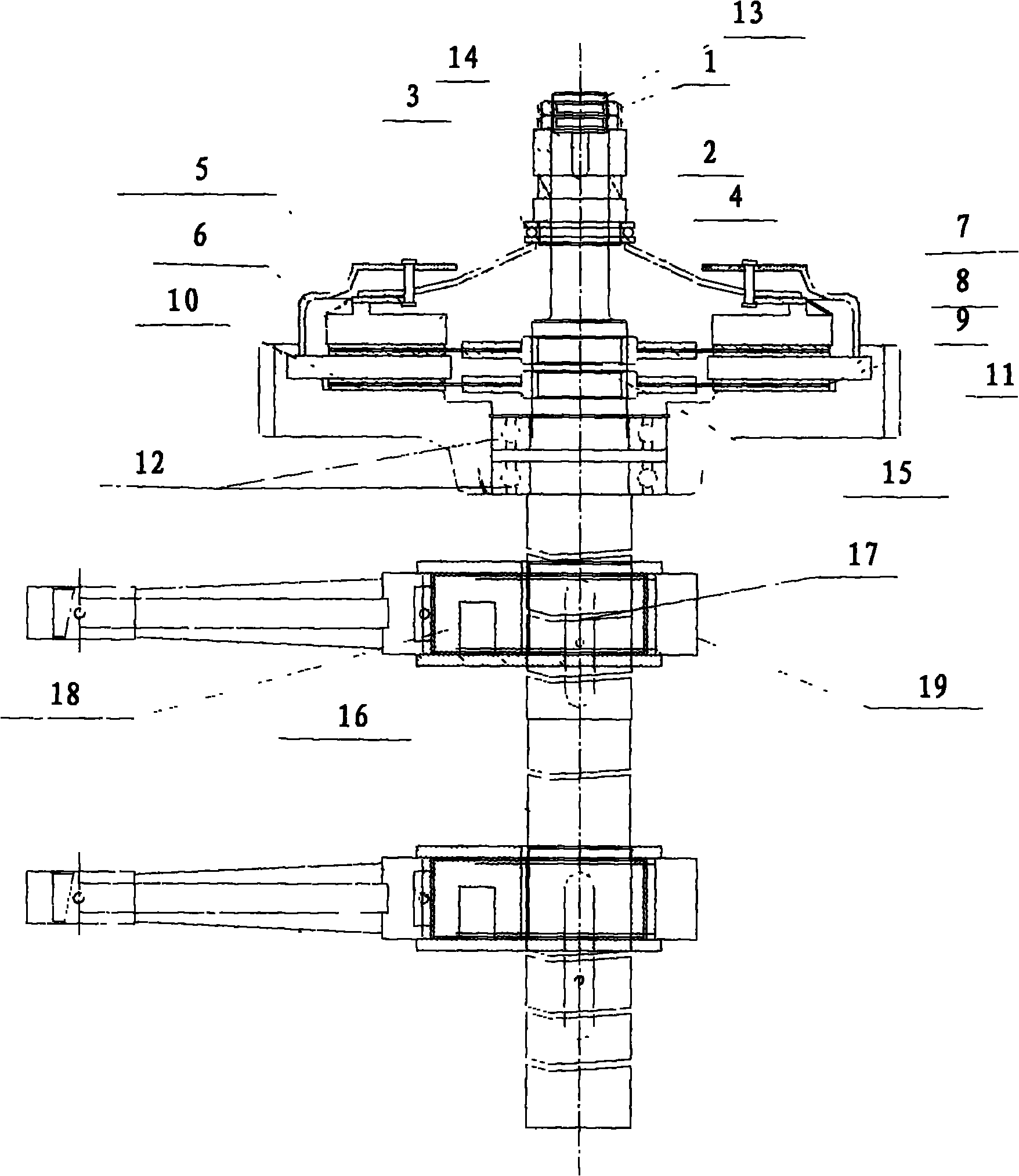

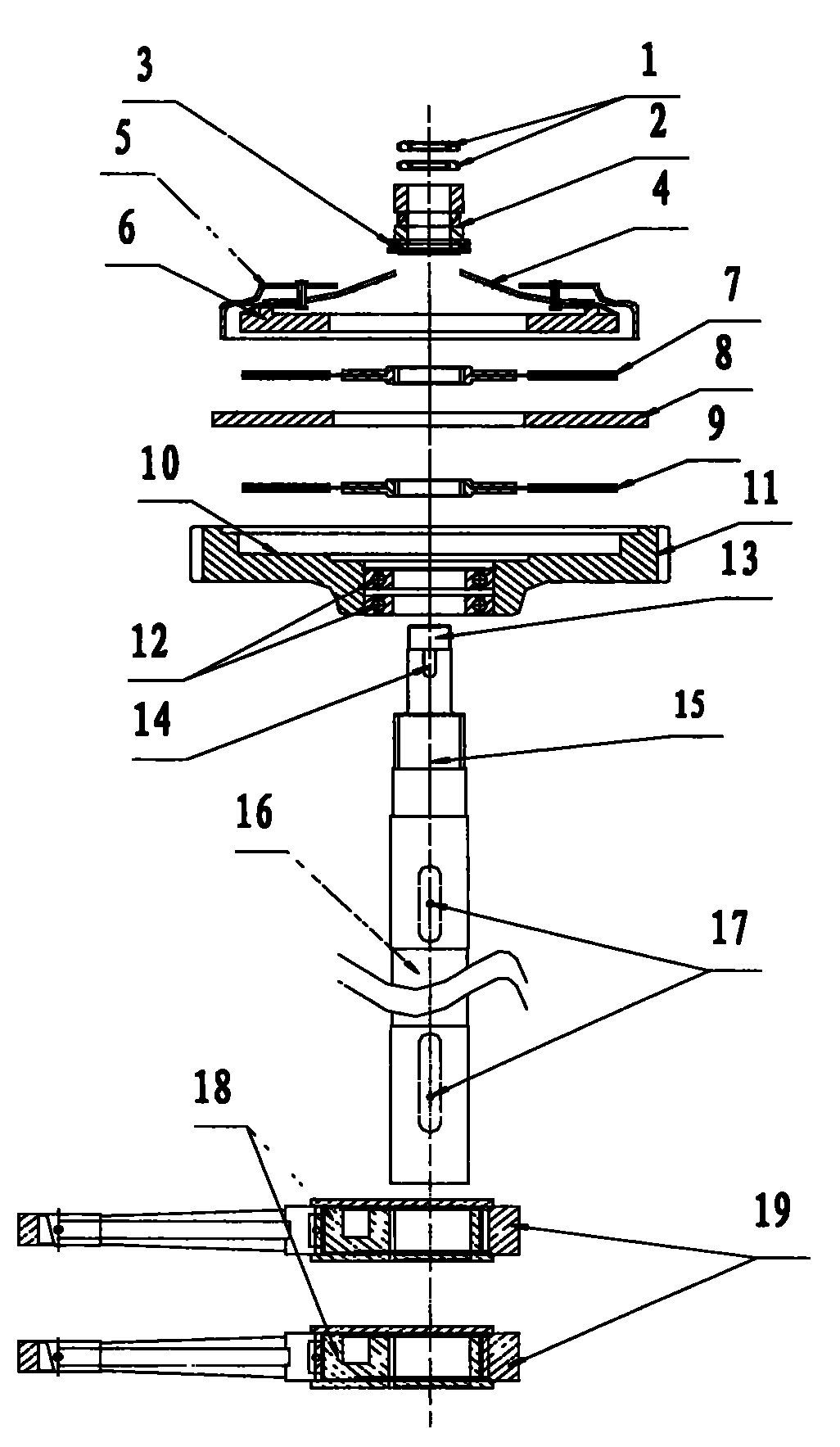

[0017] figure 1 , figure 2 The structure of the shearing machine friction brake of this embodiment is shown respectively from assembly and actual structure.

[0018] The friction brake mechanism of the shearing machine of this embodiment comprises the main shaft 16 of the shearing machine, the eccentric wheel 18, and the rod 19. The axial direction of the main shaft 16 is provided with two keyways 17, and the two eccentric wheels 18 are respectively sleeved on the On the keyway 17, and fixed by the key. A bearing 12 is sleeved on one side of the main shaft; the outer edge surface of the bearing 12 is in interference fit with the large gear 11, the outer surface of the large gear 11 is the gear frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com