Automatic assembling machine for automobile door hinge

A technology for assembly machines and door hinges, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of elastic deformation of closed-loop conveyor belts, increase production costs for manufacturers, and high failure downtime rates, and achieve overall volume reduction. Operational cost and the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

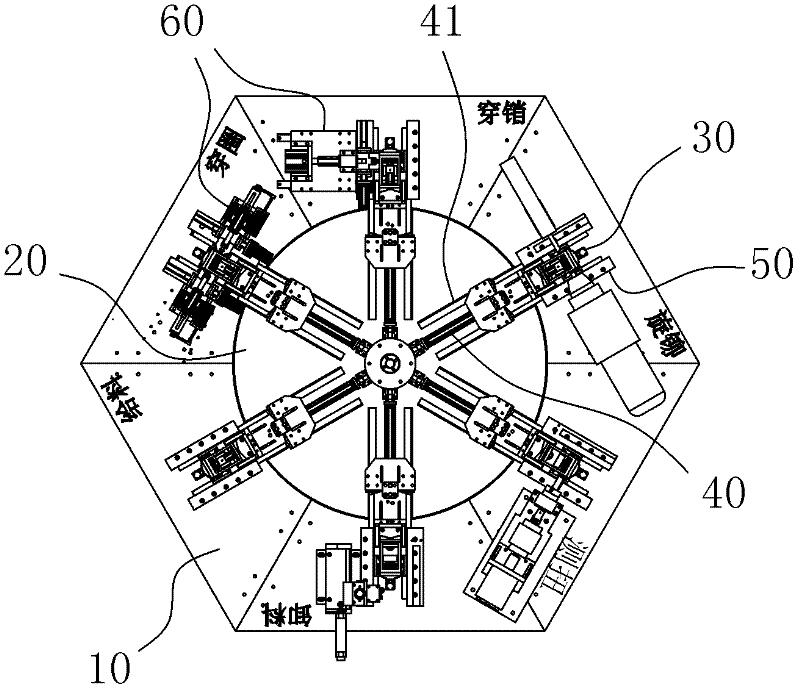

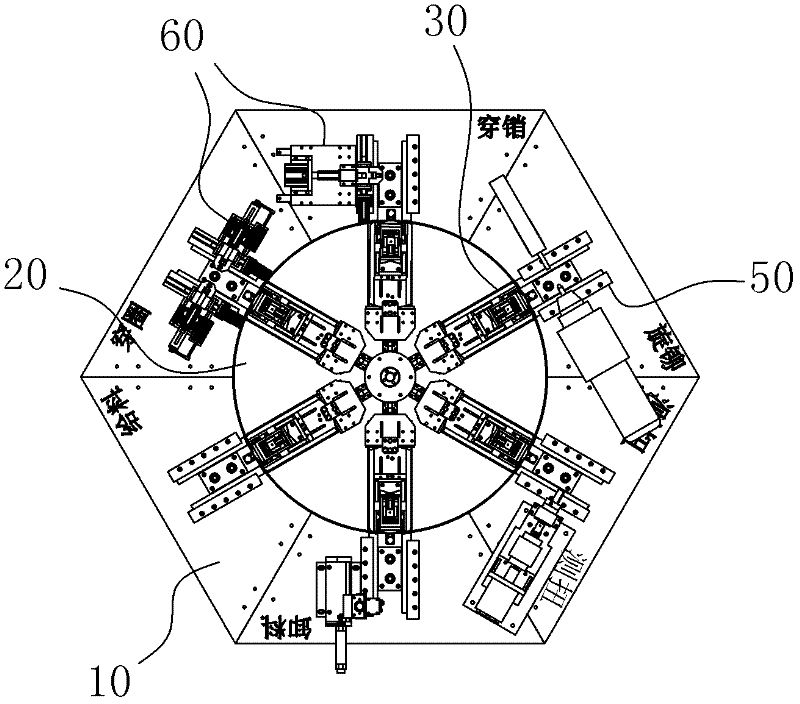

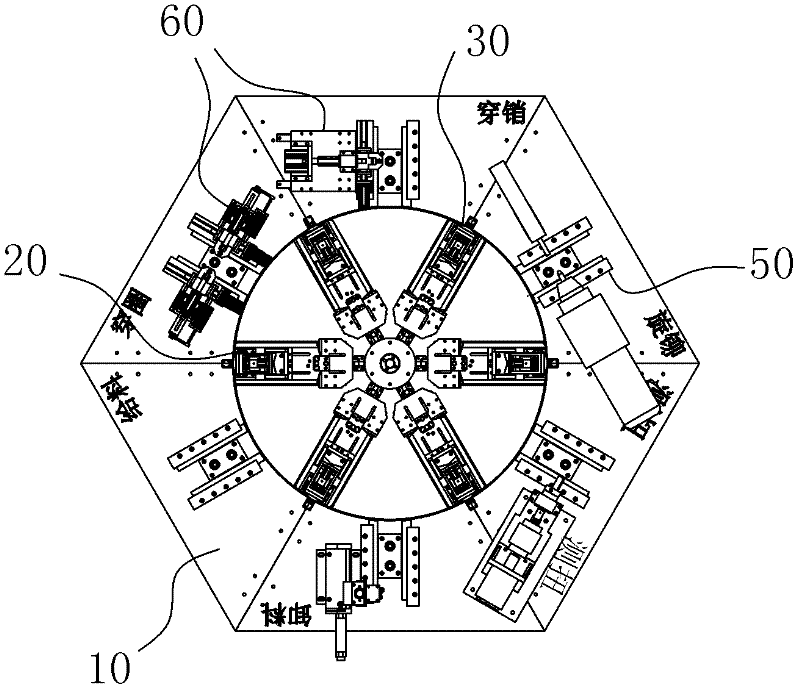

[0009] An automatic assembly machine for automobile door hinges. The assembly machine includes an annular plate 10 and a transfer turntable 20 arranged in the middle of the ring plate 10. The transfer turntable 20 rotates intermittently. The clamp 30, the transmission turntable 20 is also provided with a push mechanism 40 for pushing the clamp 30 to move radially along the surface of the transmission turntable 20, and the surface of the annular plate 10 is arranged with a clamp positioning mechanism 50 and a process execution mechanism 60, so The push mechanism 40 has two position states, one of which is that the push fixture 30 extends out of the transfer turntable 20 to the position of the fixture positioning mechanism 50 so that the process actuator 60 can carry out the process assembly, and the other position state is after the process is completed. Drive the clamp 30 to retract the transfer carousel 20 and disengage from the clamp positioning mechanism 50 assembled in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com