Cambered surface cam grinding center based on reducing grinding wheel grinding

A technology of arc cam and grinding center, which is applied in the direction of abrasive belt grinder, etc., can solve the problems of low grinding efficiency, low efficiency, and the surface quality of the processed surface cannot achieve good results, so as to achieve good grinding quality and high grinding efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

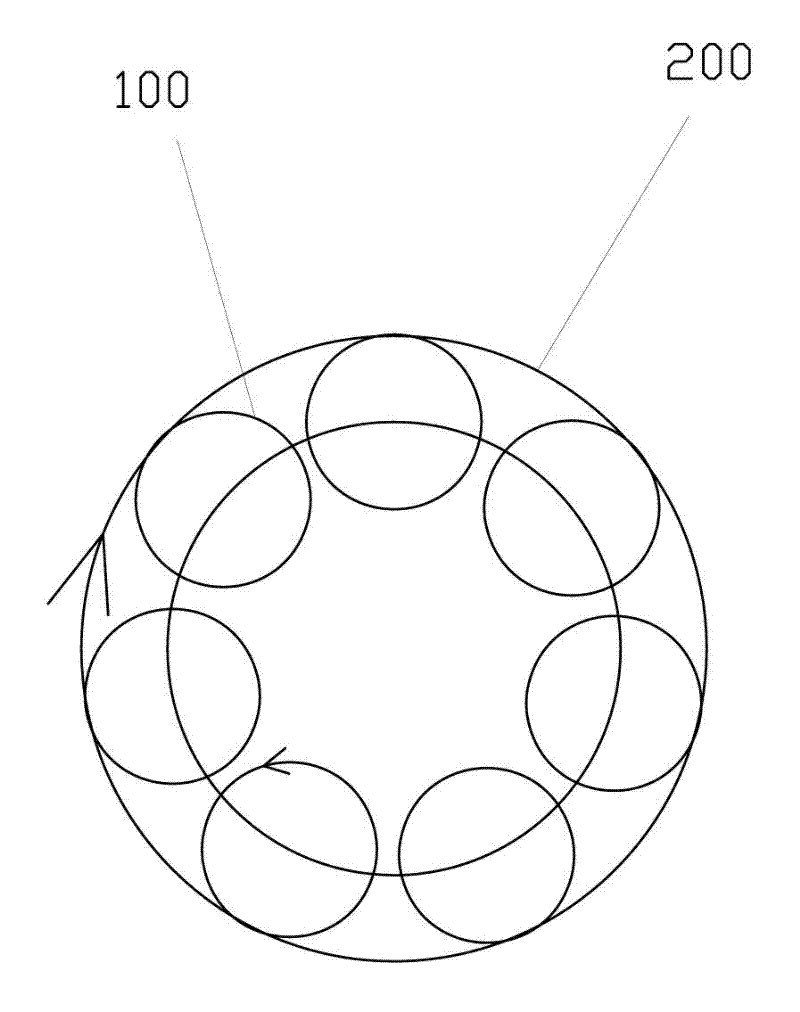

[0027] The basic idea of the method of the present invention is to provide a grinding center, when the arc cam is processed, the diameter of the grinding wheel used can be changed to compensate for the wear of the grinding wheel during the grinding process, so that the outer diameter of the grinding wheel It remains stable during the grinding process, so that the planetary grinding method used in the prior art can be completely abandoned.

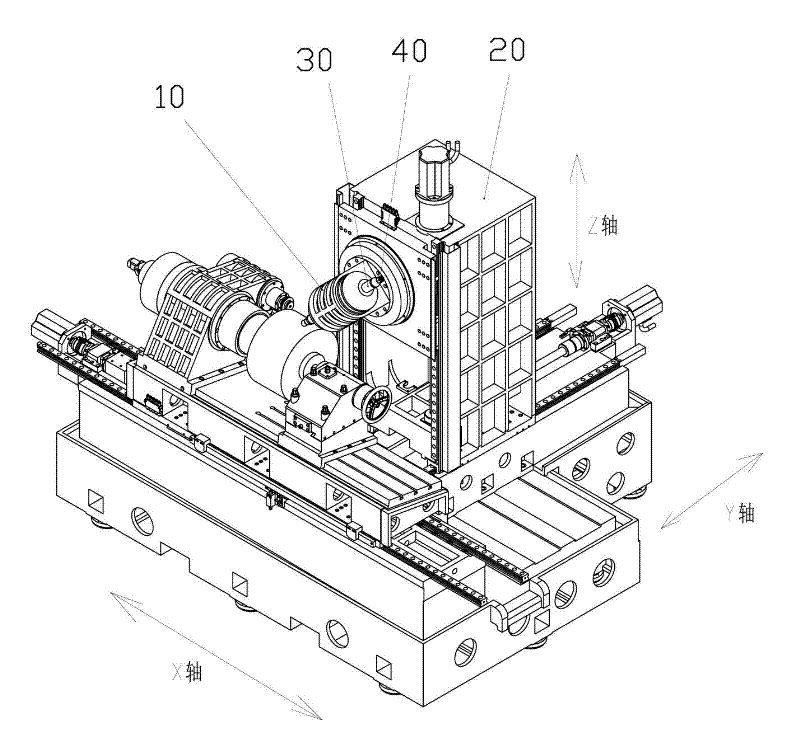

[0028] refer to figure 2 , a schematic structural composition diagram of an embodiment of the present invention, which shows various parts of a typical grinding center, wherein the grinding wheel headstock 10 is installed on the column 20, and the grinding wheel headstock 10 is equipped with a grinding wheel spindle 30, A grinding wheel 40 is installed on the grinding wheel spindle 30, and the grinding wheel 40 is a variable-diameter grinding wheel with variable diameter. The remaining components of the bed shown in the figure do not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com