Semi-extruded one-step extrusion forming mold for flame-retardant 8-shaped optical cables

A molding die and semi-extrusion technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of large short shaft outer diameter, poor extrusion fluidity, low production speed, etc., to achieve stable wall thickness and outer diameter, and process Easy to adjust, smooth and clean appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

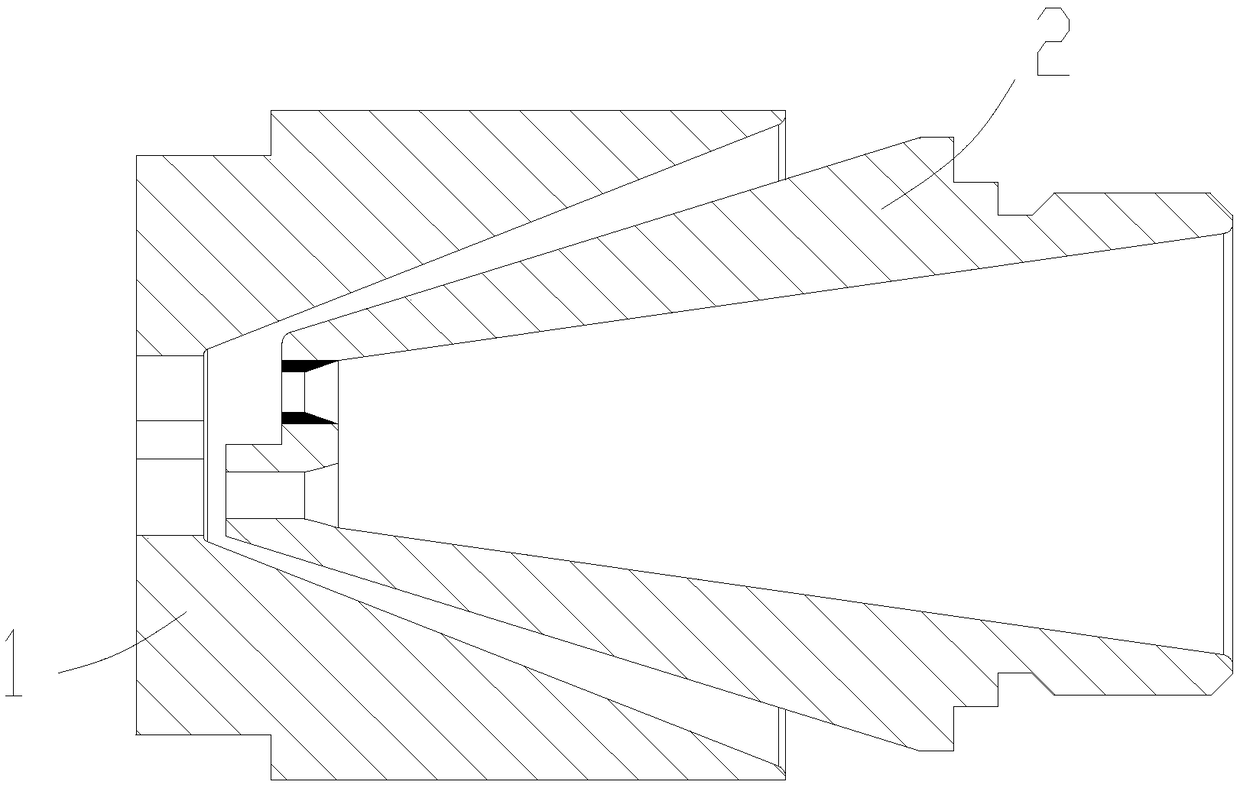

[0023] like figure 1 As shown, this embodiment is a semi-extrusion one-time extrusion molding mold for a flame-retardant 8-shaped optical cable, which is composed of a mold sleeve 1 and a matching mold core 2 .

[0024] Among them, the mold cover 1 is provided with a tapered inner hole, the surface of the tapered inner hole is a mirror-like glossy surface, and its surface roughness Ra is 0.025 μm; one end of the mold cover 1 is an "8"-shaped reinforced core wire and a cable core wire. And the molding die of the connecting body of the two.

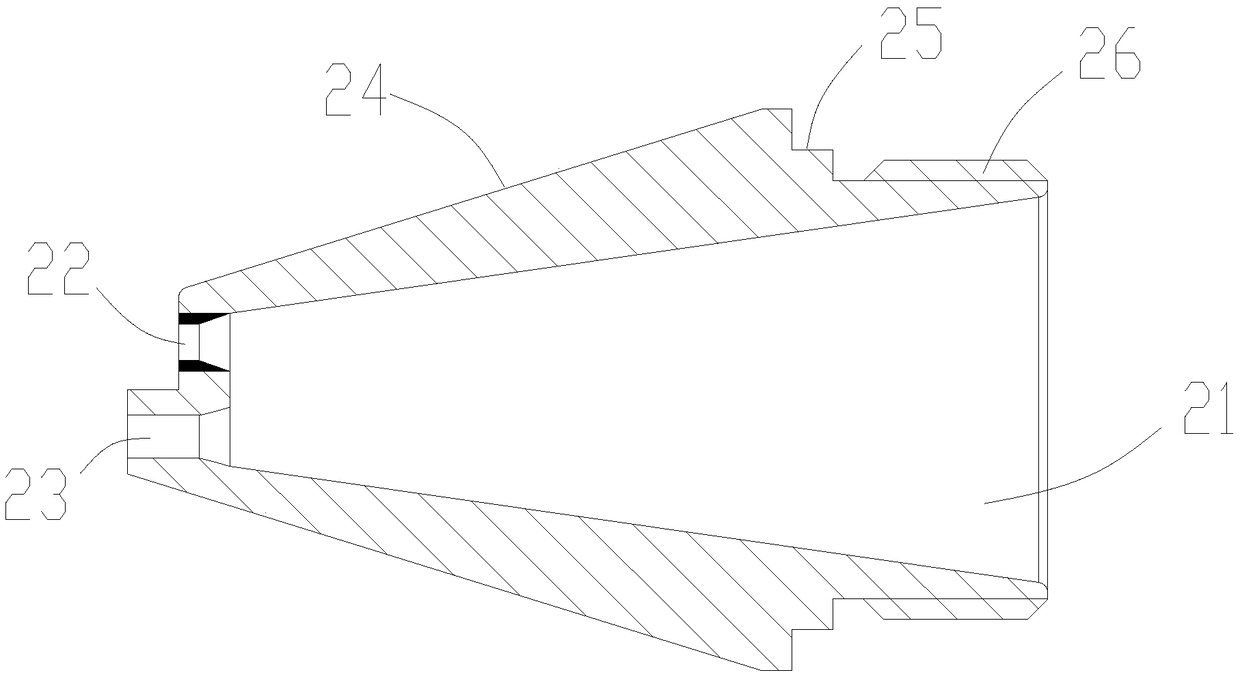

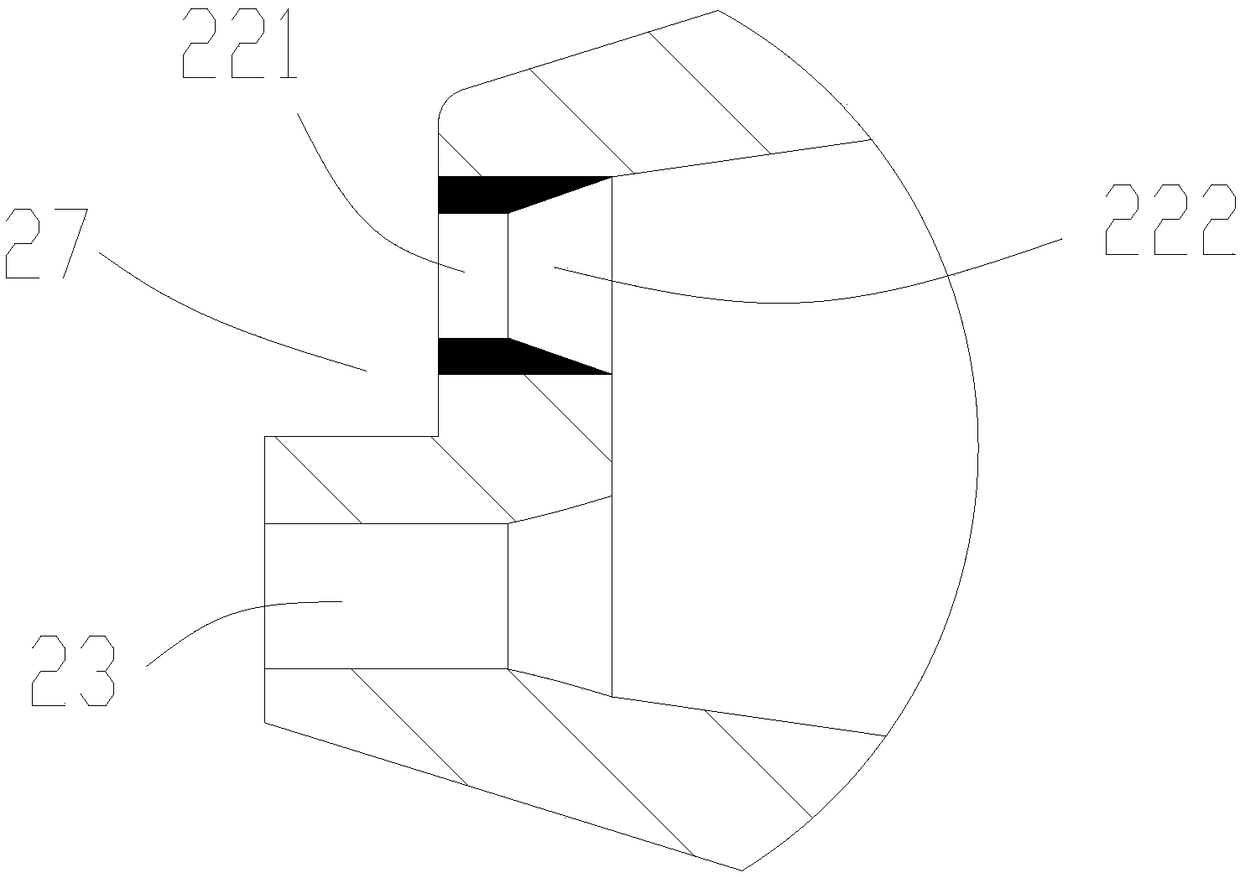

[0025] The mold core 2 is provided with a conical guide surface 24 matching the tapered inner hole of the mold sleeve 1. The surface of the conical guide surface 24 is a mirror-like glossy surface, and its Ra is 0.025 μm, such as figure 2 As shown, the mold core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com