Modified phospholipid fat-liquoring agent and preparation method thereof

A fatliquoring agent and modification technology, which is applied in the field of modified phospholipid fatliquor and its preparation, can solve the problems of low HLB value, poor hydrophilicity, unsuitable for light leather white leather fatliquor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

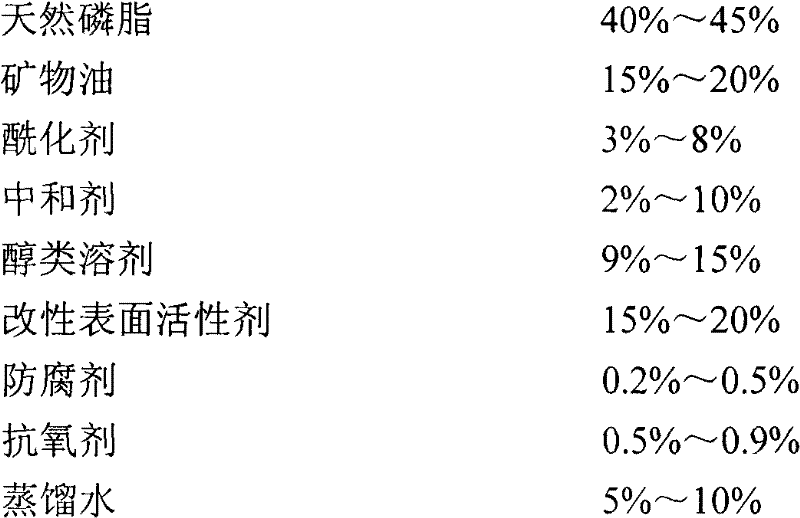

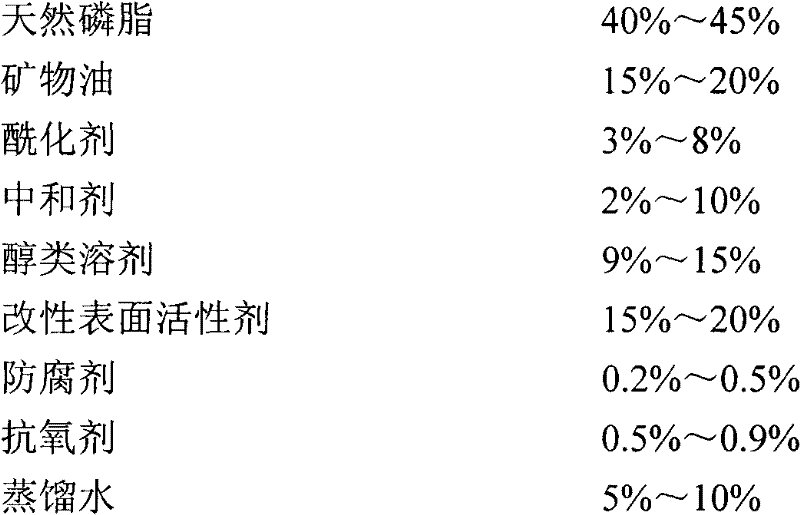

Method used

Image

Examples

Embodiment 1

[0014] Add 400kg of natural phospholipids, 167kg of mineral oil, and 40kg of acylating agent into a 1000L enamel reaction kettle equipped with a stirrer, a thermometer and a condenser, raise the temperature to 95-100°C, and keep the temperature for 3.5 hours; cool down to 50-55°C, Add 5kg of antioxidant, stir for 0.5 hours; add 31.1kg of neutralizer, adjust the pH value of the system to 6.5, then add 97kg of alcohol solvent, 185.7kg of modified surfactant, 2kg of preservative, and keep the temperature at 50~ Stir at 60°C for 1 hour; slowly add 70.1kg of distilled water, fully stir for 3 hours, cool down and discharge to obtain 997.9kg of modified phospholipid fatliquor with an oil content of 87%.

Embodiment 2

[0016] Add 400kg of natural phospholipids, 172kg of mineral oil, and 43kg of acylating agent into a 1000L enamel reaction kettle equipped with a stirrer, thermometer and condenser, raise the temperature to 95-100°C, and keep it warm for 4 hours; cool down to 50-55°C, Add 5kg of antioxidant, stir for 0.5 hours; add 32.7kg of neutralizer, adjust the pH value of the system to 7.5, then add 99kg of alcohol solvent, 190.4kg of modified surfactant, 2kg of preservative, and keep the temperature at 50~ Stir at 60°C for 1 hour; slowly add 62.7kg of distilled water, fully stir for 3.5 hours, cool down and discharge to obtain 1006.9kg of modified phospholipid fatliquor with an oil content of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com