Preparation method of sulphonating succinate ester disodium salt combined leather currying agent

A technology of sulfonated succinate and leather fatliquor, which is applied in leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve the problem of effective substances Low content, difficult water emulsification, poor lightfastness of fatliquored leather, etc., to achieve good smoothness, clean production process, and good lightfastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

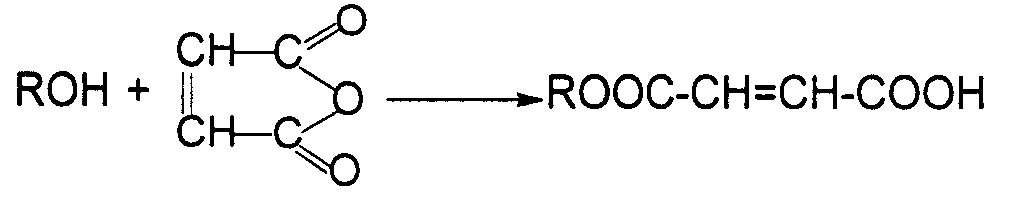

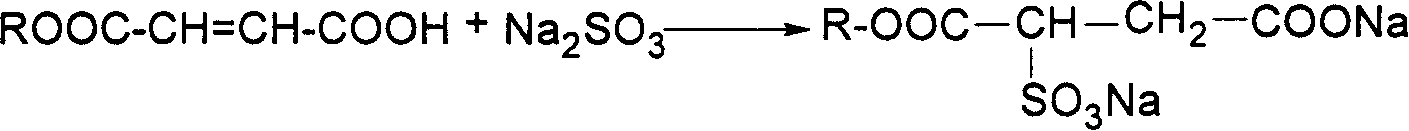

Method used

Image

Examples

Embodiment 1

[0031] Add 40.0g lanolin alcohol containing hydroxyl, 30.0g castor oil and 30.0g special rapeseed oil fatty acid acyldiethanolamine to a dry three-necked flask, raise the temperature to 65°C, stir evenly, add 22.0g maleic anhydride in batches, and then Raise the temperature to 88°C for esterification, react for 2.5h~3.0h, cool down to 70°C, add 29.42g of anhydrous sodium sulfite to it, then add 121.83g of hot water at 65°C~75°C, raise the temperature to 80°C for 120min, cool down to 45°C ℃~50℃, the sulfosuccinate disodium salt combined leather fatliquoring agent can be obtained after discharge. The appearance of the fatliquoring agent is yellow ointment, and the softness of the fatliquor leather is good.

Embodiment 2

[0033] Add 45.0g of lanolin alcohol containing hydroxyl, 30.0g of castor oil and 25.0g of special rapeseed oil fatty acid acyldiethanolamine to a dry three-necked flask, raise the temperature to 65°C, stir evenly, add 28.0g of maleic anhydride in batches, and then Raise the temperature to 90°C for esterification, react for 2.5h~3.0h, cool down to 70°C, add 37.8g of anhydrous sodium sulfite to it, then add 121.83g of hot water at 65°C~75°C, raise the temperature to 80°C for 150min, cool down to 45°C ℃~50℃, the sulfosuccinate disodium salt combined leather fatliquoring agent can be obtained after discharge. The appearance of the fatliquoring agent is yellow-white paste, and the fatliquoring leather has a strong waxy feeling, good filling performance, good light resistance and strong binding ability.

Embodiment 3

[0035] Add 46.0g lanolin alcohol containing hydroxyl group, 28.0g castor oil and 26.0g special rapeseed oil fatty acid acyldiethanolamine to a dry three-necked flask, heat up to 65°C, stir evenly, add 24.0g maleic anhydride in batches, and then Raise the temperature to 92°C for esterification, react for 3.0h to 3.5h, cool down to 70°C, add 32.4g of anhydrous sodium sulfite to it, then add 132.94g of hot water at 65°C to 75°C, raise the temperature to 82°C for 100min, cool down to 45°C ℃~50℃, the sulfosuccinate disodium salt combined leather fatliquoring agent can be obtained after discharge. The appearance of the fatliquoring agent is yellow-white paste, and the fatliquoring leather has a strong waxy feeling, good filling property and good light fastness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com