Metal-organic chemical vapor deposition machine

A chemical vapor deposition and organometallic technology, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of increasing process cost, reducing the output quantity of components, increasing the output quantity of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

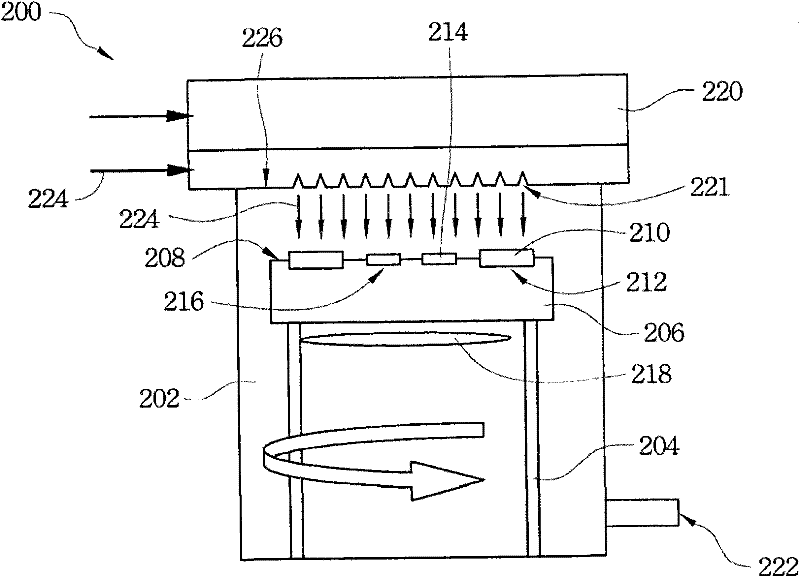

[0036] Please refer to figure 2 , which shows a schematic diagram of a metalorganic chemical vapor deposition machine according to an embodiment of the present invention. In this embodiment, the metalorganic chemical vapor deposition tool 200 is suitable for epitaxy of the semiconductor material layer of the light emitting diode. The metalorganic chemical vapor deposition tool 200 may, for example, include a reaction chamber 202 , a spin base 204 , a wafer carrier 206 , a heater 218 , and a gas spray head 220 .

[0037] In the metalorganic chemical vapor deposition tool 200 , the reaction chamber 202 generally has an opening 226 to facilitate placing several wafers on the wafer carrier 206 through the opening 226 . In addition, according to process requirements, the reaction chamber 202 may optionally include at least one exhaust port 222 . The exhaust port 222 can be disposed, for example, at the lower part of the reaction chamber 202 , so as to facilitate the discharge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com