Combined yarn separating plate

A splitting board and combined technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of insufficient strength, defective cloth, and non-stop when warp breaks, etc., and achieve high strength, high strength, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

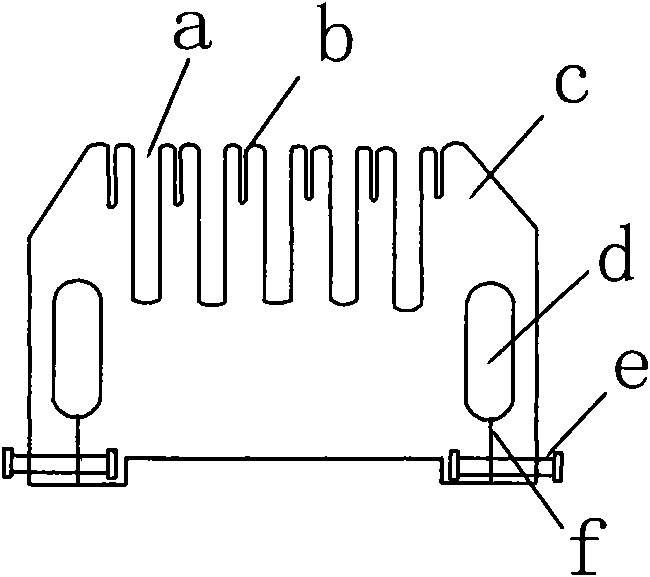

[0014] figure 1 It is the splitting board of the existing wide rapier loom, and it is an integral comb-shaped splitting board C made of plastic. The upper part of the integral comb-shaped splitting board C is provided with a warp bar slot a and a warp bar slot b , the two side boards of the overall comb-shaped yarn separating board C are provided with a long hole d, and an opening f is opened at the bottom of the long hole, and a hole is arranged laterally on the bottom end of the bottom opening f of the long hole, Bolt e is contained in the hole. The 6 rows of electronic warp-stop bars of the integral comb-shaped yarn-separating board are placed on the warp-stopping frame relying on 3 evenly distributed yarn-separating boards, and the 5 warp-stop rods are divided into 6 rows of warp-stopping bars at equal intervals to complete weaving warp let-off and warp breaking Detect and break the parking task.

[0015] exist figure 2 , image 3 and Figure 4 In the embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com