Damping valve device with a multi-stage damping characteristic curve

A damping valve, damping medium technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

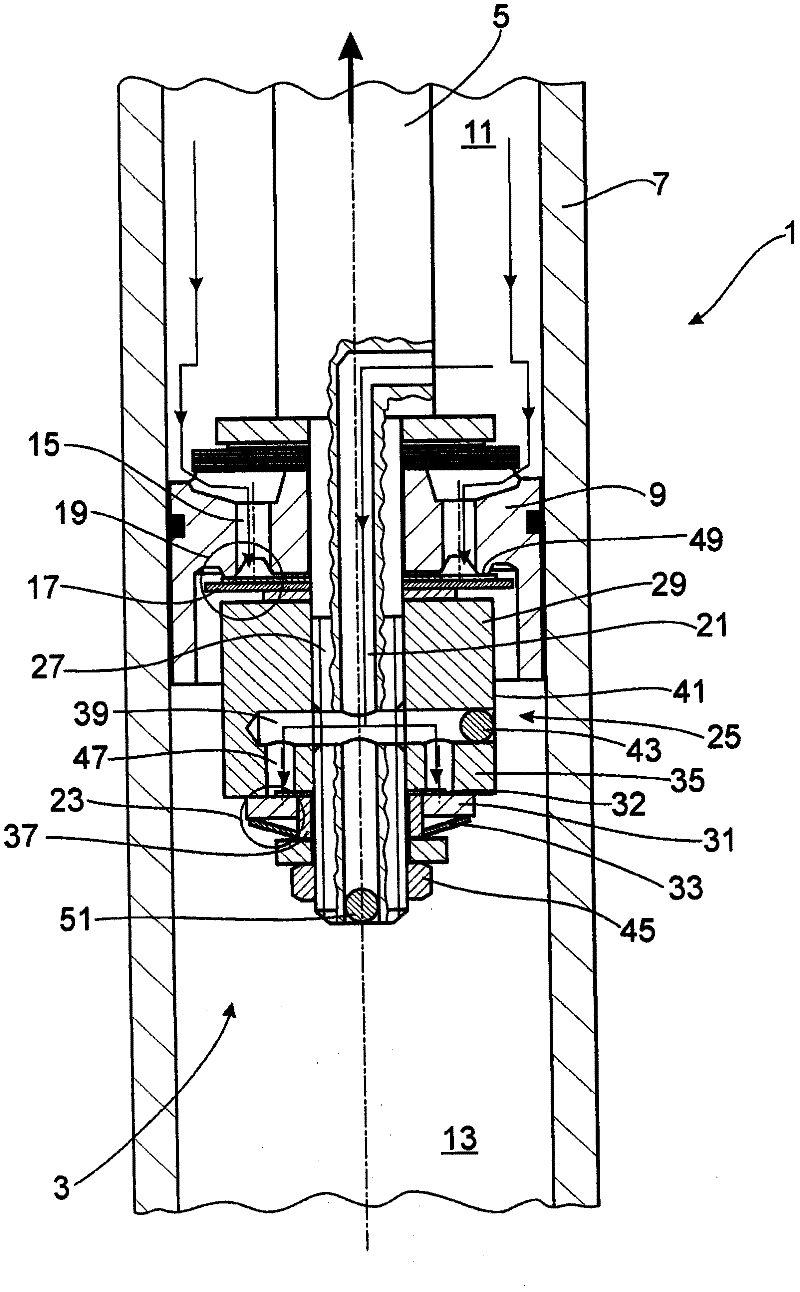

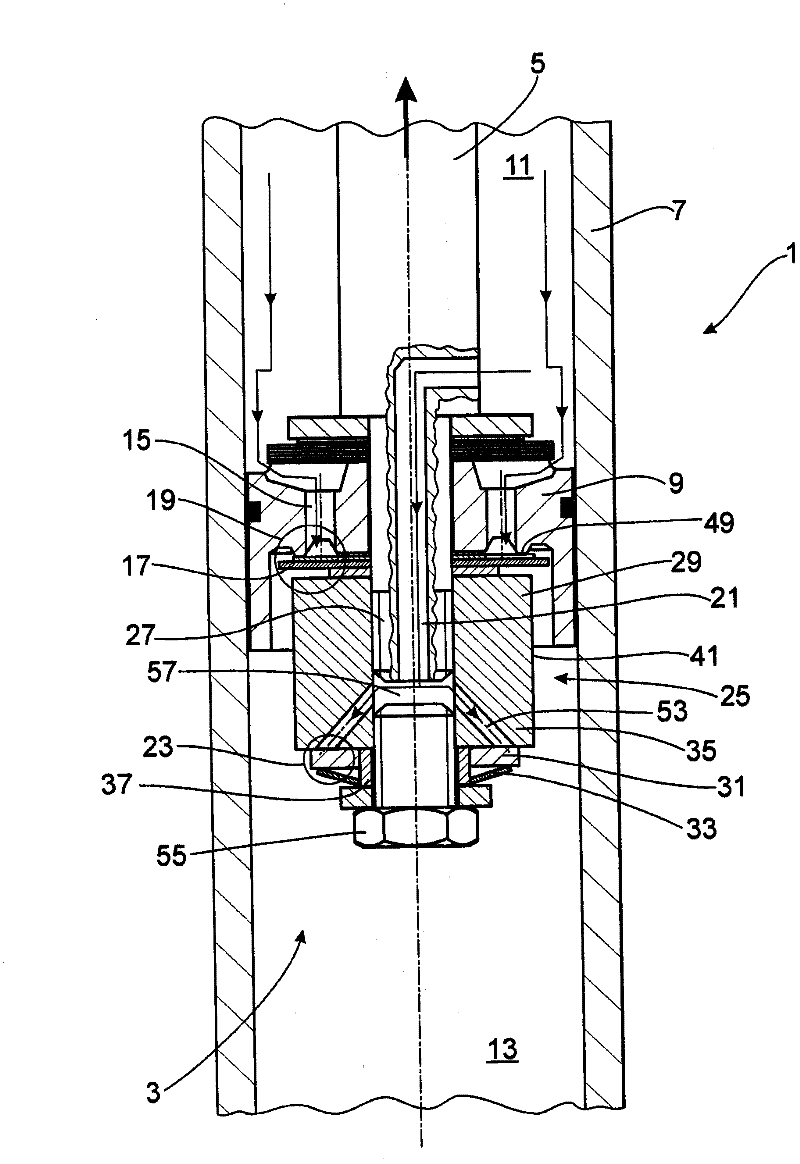

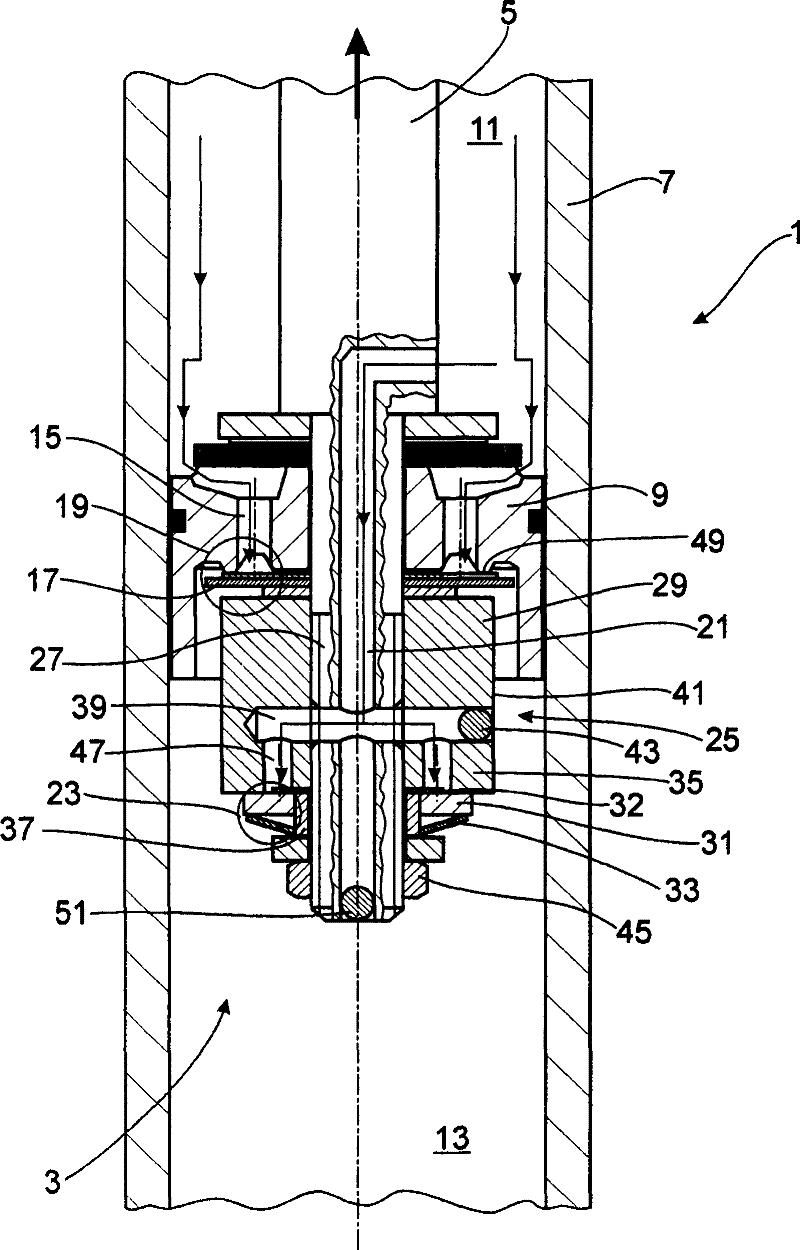

[0019] figure 1 A portion of the shock absorber 1 is shown in the region of the damping valve arrangement 3 , which is arranged in the cylinder 7 on the piston rod 5 as a carrier. The piston 9 as first damping valve body and part of the damping valve arrangement 3 divides the cylinder 7 into a piston rod-side working chamber 11 and a piston rod-distant working chamber 13 . In the piston 9, at least one throughflow channel 15 is arranged in each flow direction of the damping medium in the cylinder 7, the outlet of which is at least partly covered by at least one valve disk 17, thereby forming a first Damping valve 19. In this specific embodiment, two through-flow channels are shown for the through-flow during the extension movement of the piston rod 5 . The flow channel provided for the sliding movement is formed in another section of the piston 9 and is therefore not visible.

[0020] A flow channel 21 in the piston rod 5 is connected to the piston rod-side working chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com