Spring brake cylinder with external bleeding

A technology of energy storage brake and brake cylinder, which is applied in the direction of brakes, brake cylinders, brake components, etc., and can solve the problem that the exhaust valve is not enough to keep the exhaust valve closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

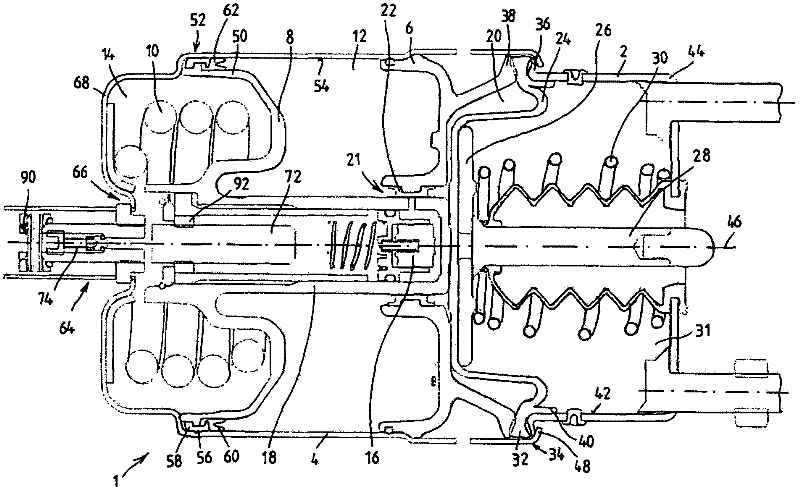

[0022] figure 1 A combined operating brake cylinder and spring-loaded brake cylinder 1 is shown in , hereinafter referred to as combined cylinder. The combined cylinder 1 is composed of a running brake cylinder 2 and a spring energy storage brake cylinder 4 which is structurally and functionally connected with it. The running brake cylinder 2 and the spring-loaded brake cylinder 4 are separated from each other by a partition wall 6 . A spring storage brake piston 8 is displaceably arranged inside the spring storage brake cylinder 4 , wherein a storage spring 10 bears against one side of the spring storage brake piston 8 . The storage spring 10 is supported on its opposite side on the underside of the spring storage brake cylinder 4 . A spring storage brake chamber 12 is designed between the spring storage brake piston 8 and the partition wall 6, which is connected to a pressure regulation module (not shown for reasons of size) for its control. Inflate and deflate. During c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com