Positive electrode for alkaline water electrolysis and method for producing positive electrode for alkaline water electrolysis

A manufacturing method, water electrolysis technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of high overvoltage and poor productivity, and achieve the effects of low overvoltage, improved corrosion resistance, and firm bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

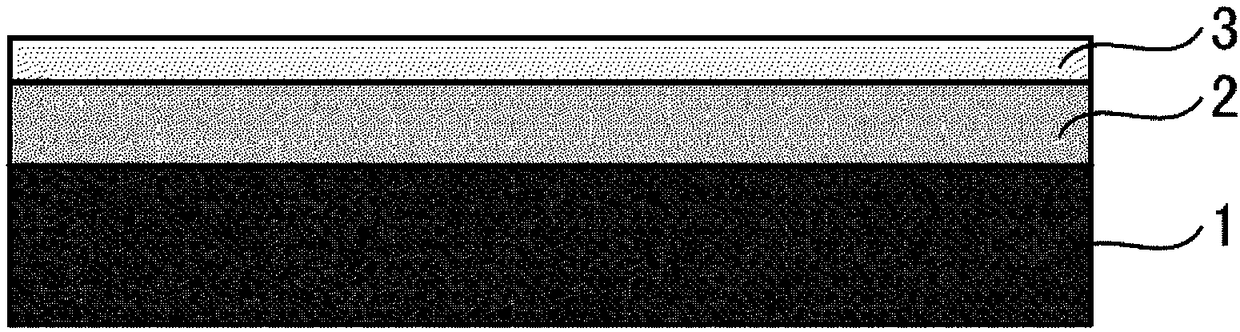

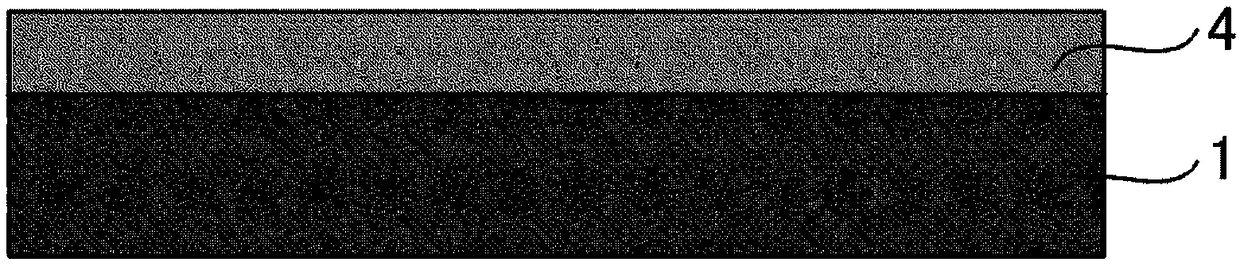

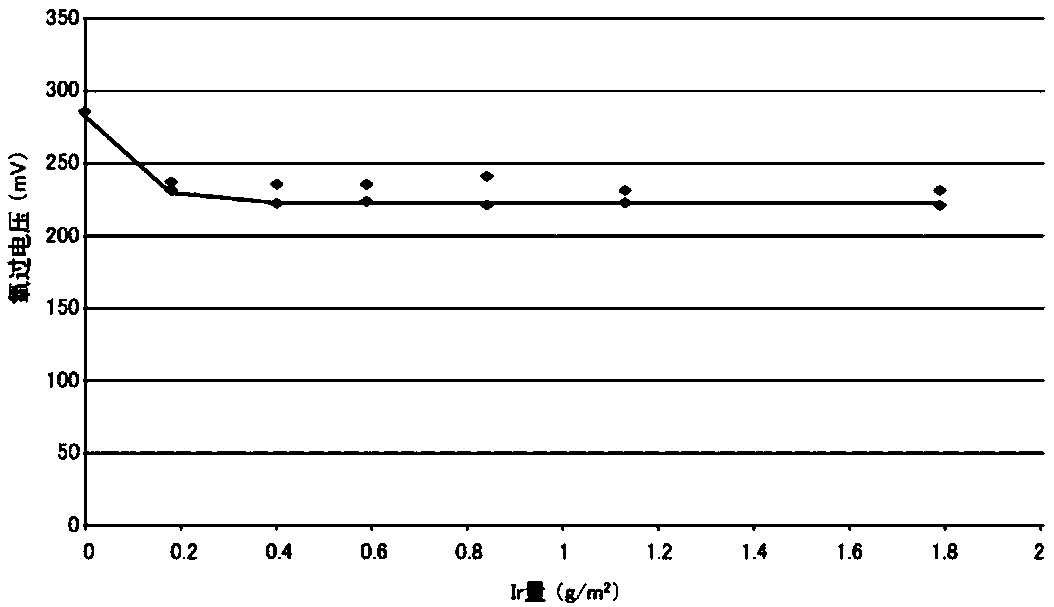

[0111] Example 1 shows the use of NiCo as the first catalyst component 2 o 4 , IrO is used as the second catalyst component 2 . An example in which the calcination temperature is set to 350° C., and the first catalyst component and the second catalyst component are formed into a laminated structure.

Embodiment 2

[0112] Example 2 shows the use of NiCo as the first catalyst component 2 o 4 , IrO is used as the second catalyst component 2 . An example in which the calcination temperature is set to 450° C., and the first catalyst component and the second catalyst component are formed into a laminated structure.

Embodiment 3

[0113] Example 3 shows the use of NiCo as the first catalyst component 2 o 4 , IrO is used as the second catalyst component 2 . An example in which the calcination temperature is set to 550° C., and the first catalyst component and the second catalyst component are formed into a laminated structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com