Main shaft for machining center machine

A machining center and spindle technology, which is used in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that the structure of the spindle device is not very ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

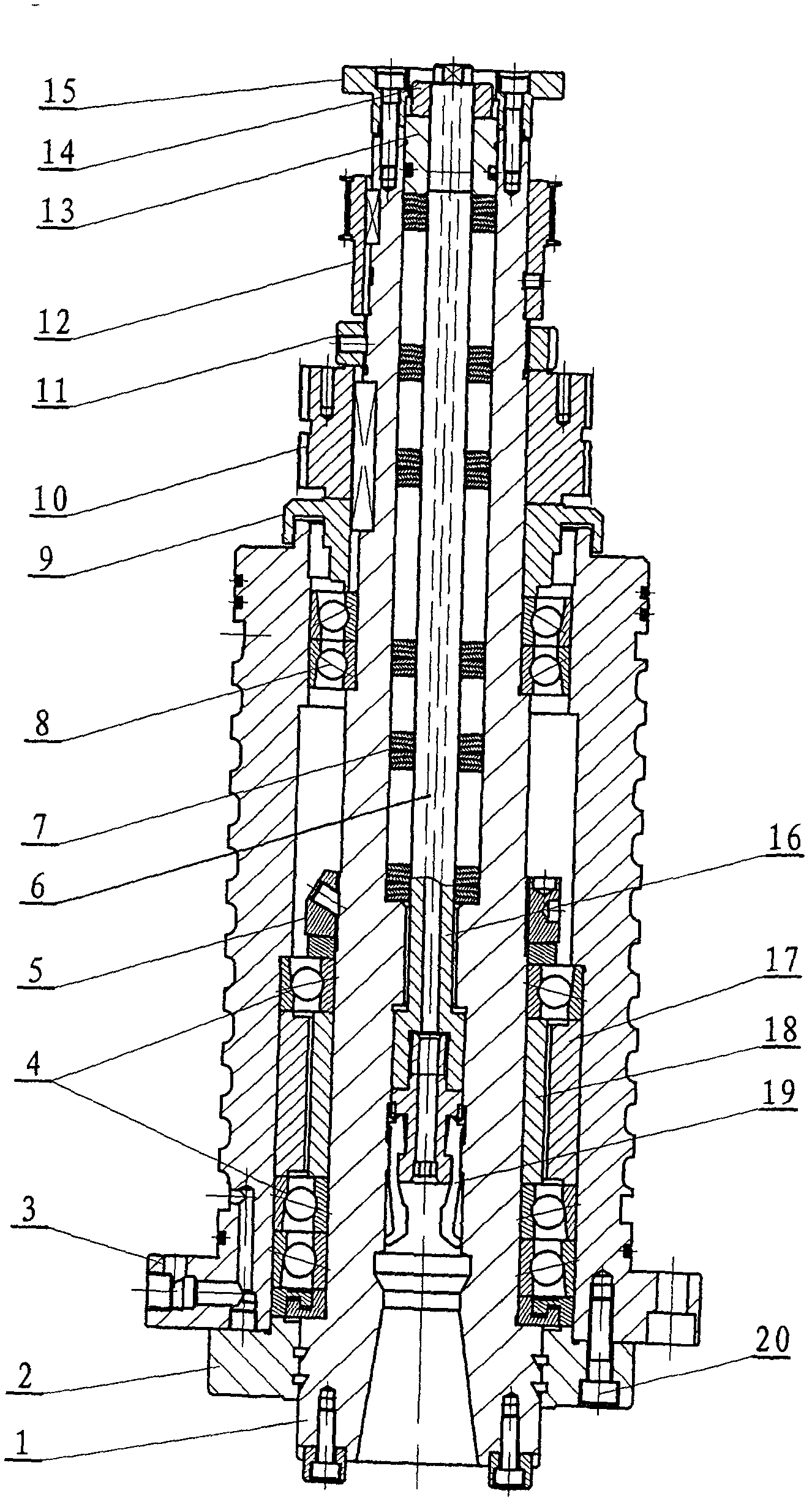

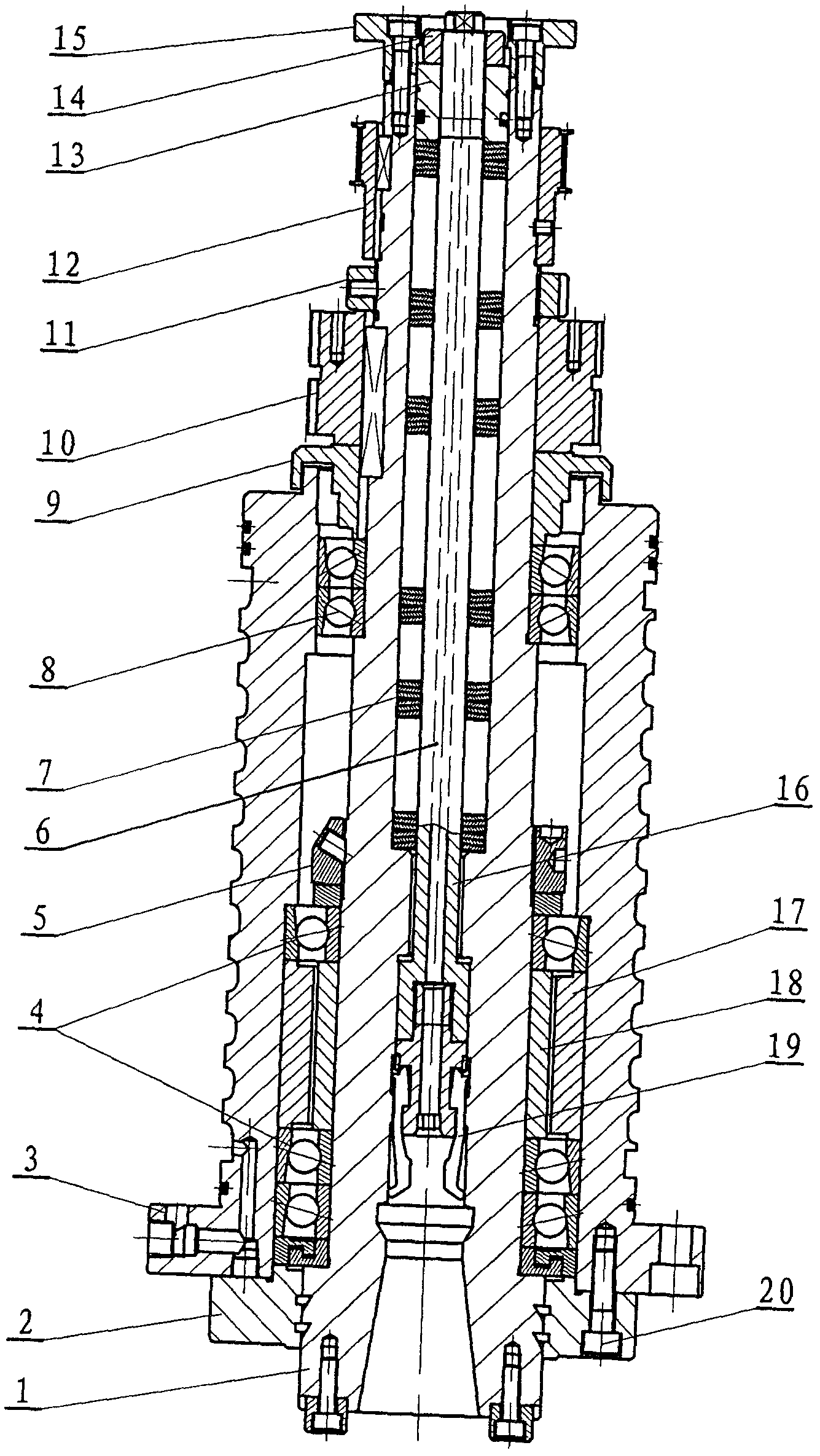

[0008] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0009] see figure 1 , a spindle for a machining center, which includes a shaft core 1, a shaft seat 3, the shaft core 1 is combined with the shaft seat 3 through 7014C bearing 4, 7012C bearing 8, and the front end cover 2 and the first spacer 17 pass through the flange The bolts 20 on the disk tighten the outer ring of the 7014C bearing 4, while the inner ring of the 7014C bearing 4 is fixed on the shaft core 1 through the first lock nut 5 and the second spacer 18, and the outer ring of the 7012C bearing 8 does not The inner ring is fixed on the shaft core 1 through the second lock nut 11, the first circular arc toothed pulley 10, and the dust cover 9, the ejector rod 16 is installed in the shaft core 1, and the four-petal claw 19 is installed on the top Under the rod 16, the ejector rod 16 bears the upward force of the disc spring 7 through the nut 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com