Method for processing back-spraying hole in shell of rocket chamber by using conventional boring machine

A combustion chamber and reverse injection hole technology, which is used in boring/drilling, metal processing equipment, metal processing machinery parts, etc., can solve the problems of expensive, difficult to process high-precision reverse injection holes, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

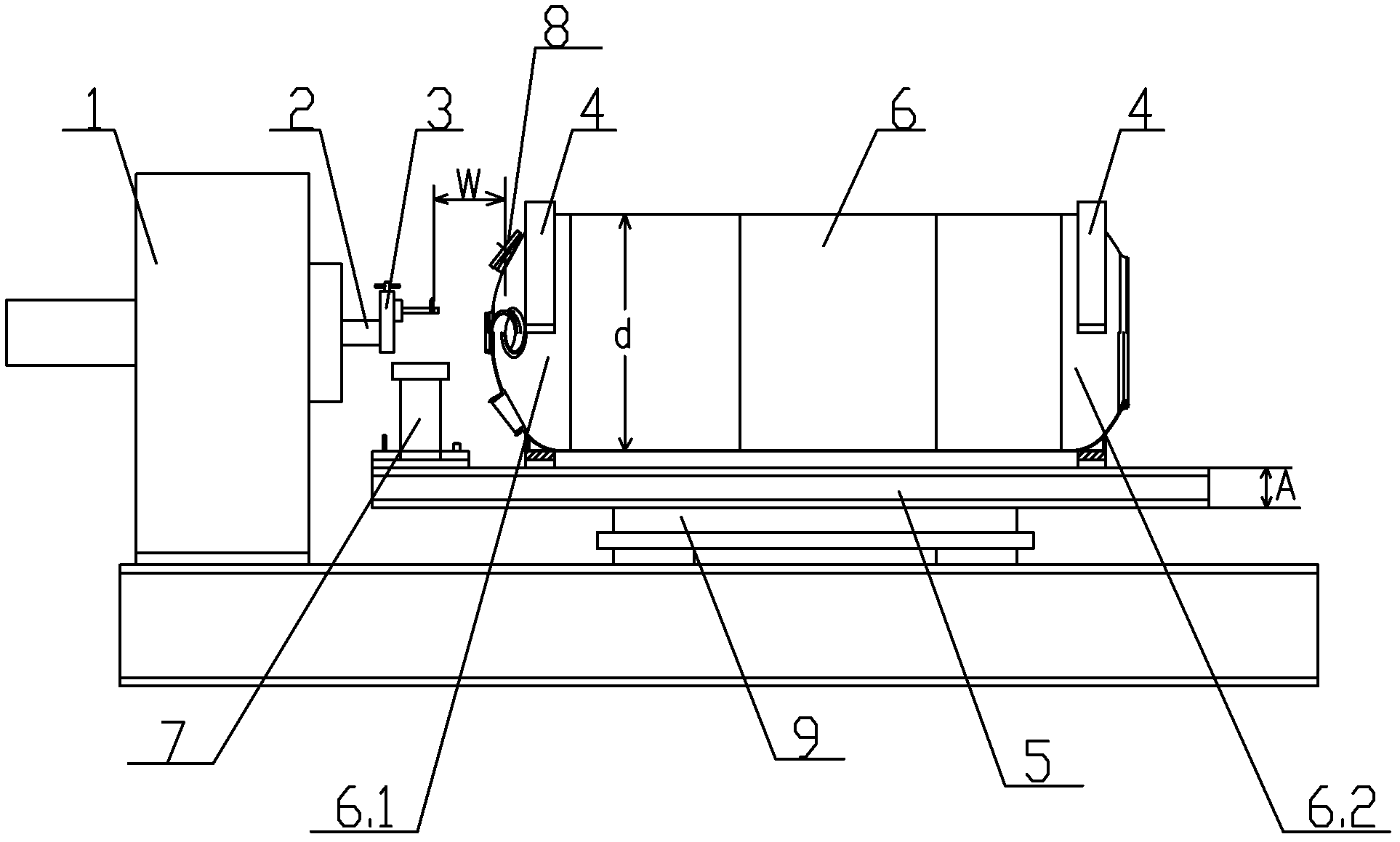

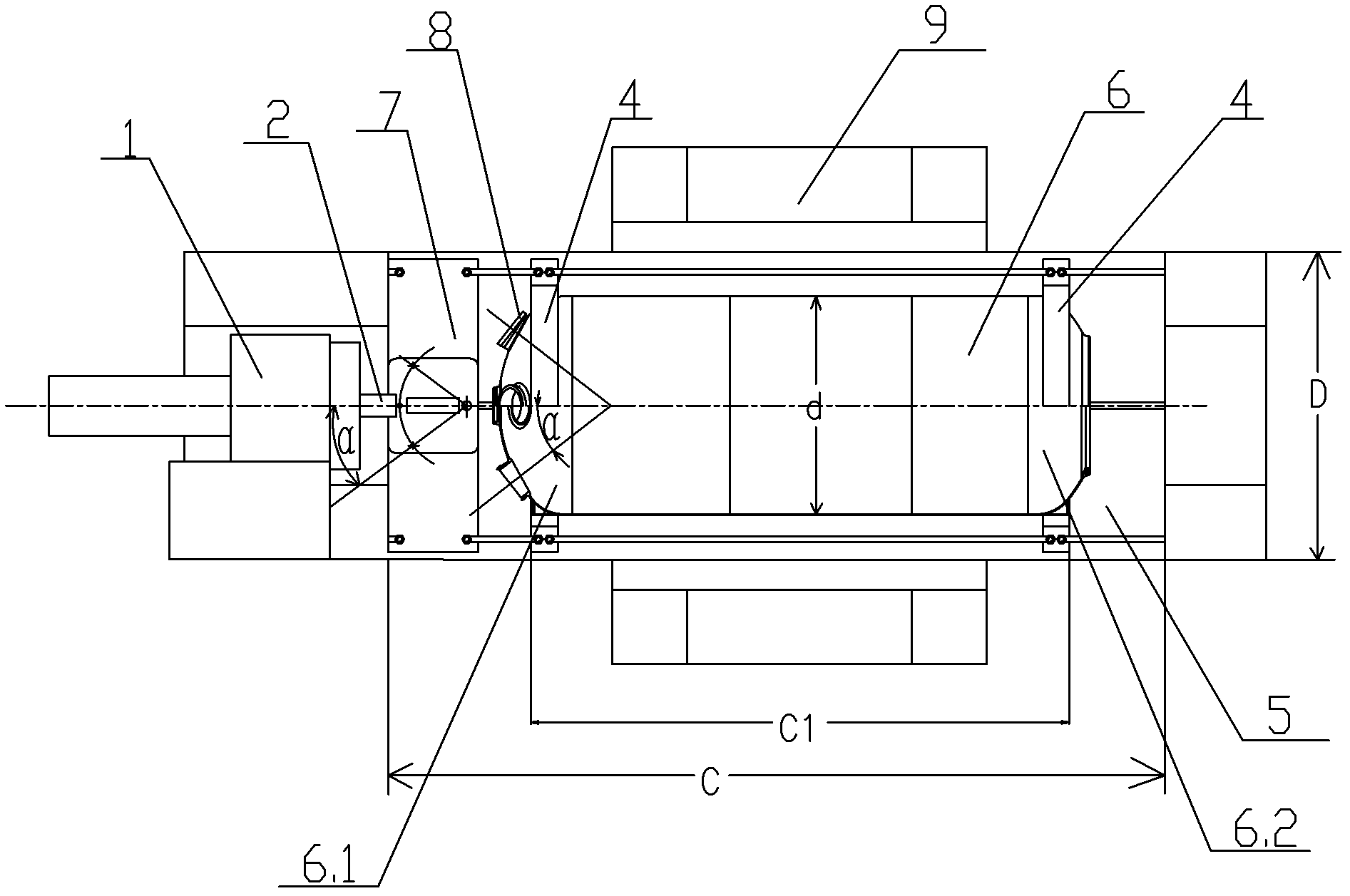

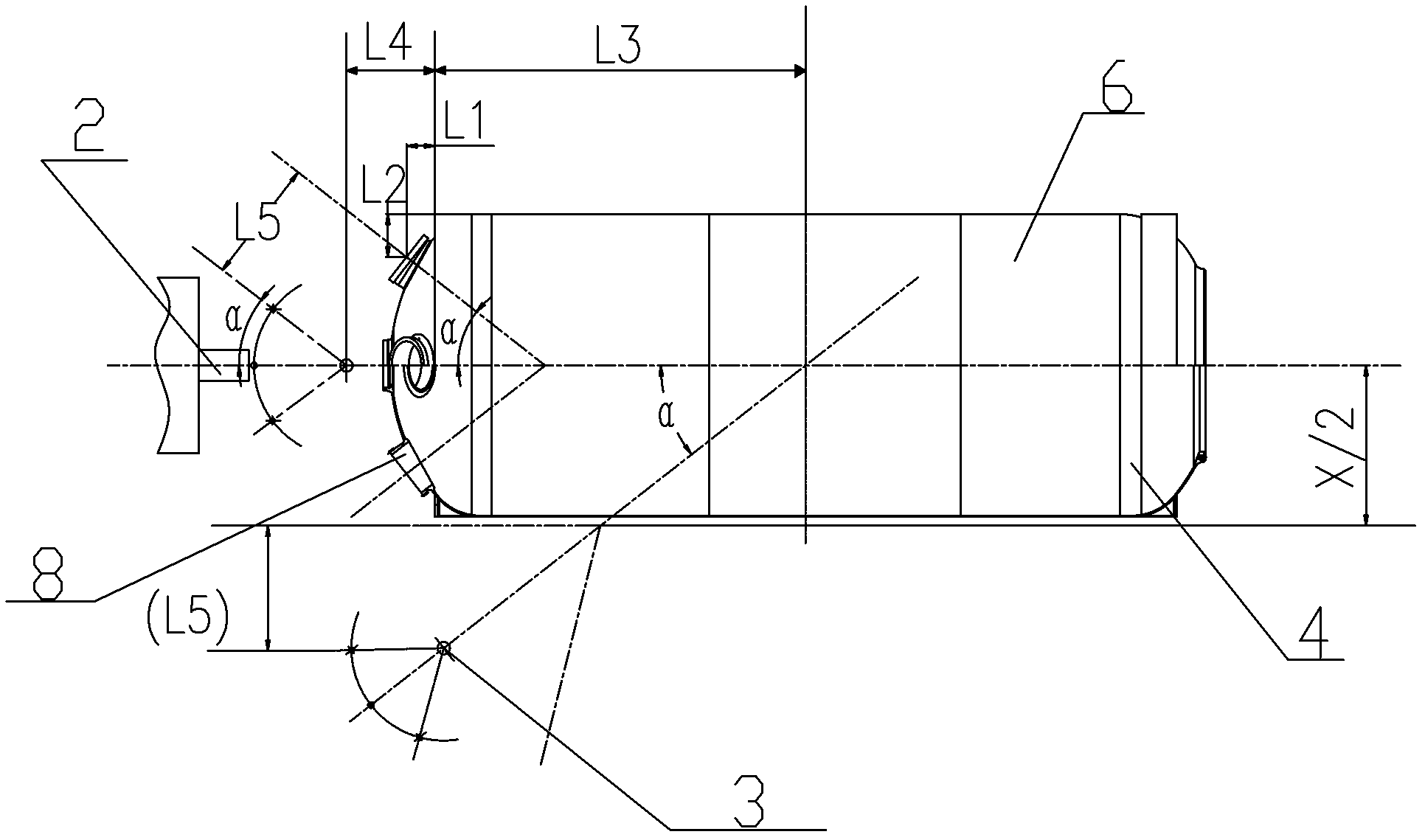

[0055] For a certain aircraft Φ880mm×5000mm rocket combustion chamber casing 6, the outer diameter of the front skirt 6.1 is d=880mm. The included angle between the anti-spray hole 8 and the axis center of the rocket combustion chamber casing 6 is α=38°, and the distance L between the center of the end face of the anti-spray hole 8 and the end face of the front skirt 6.1 1 =82.8mm, the distance L from the center of the end surface of the anti-spray hole 8 to the outer circle of the front skirt 6.1 2 = 125.25 mm. The distance L from the center of rotation of the horizontal worktable 9 to the end face of the front skirt 6.1 3 =2500mm. The length C=5600mm of the special platform 5, the width E=1250mm of the special platform 5, and the thickness A=250mm of the special platform 5. The distance B=100mm from the tangent line of the inner arc surface of the bracket base 4.3 lower end of the special bracket 4 to the lower end bottom surface of the bracket base 4.3. The distance L f...

Embodiment 2

[0068] For a certain aircraft Φ1200mm×6000mm rocket combustion chamber casing 6, the outer diameter of the front skirt 6.1 is d=1200mm. The angle between the anti-spray hole 8 and the axis center of the rocket combustion chamber casing 6 is α = 40°, and the distance L between the center of the end face of the anti-spray hole 8 and the end face of the front skirt 6.1 1 =136.3mm, the distance L from the center of the end surface of the anti-spray hole 8 to the outer circle of the front skirt 6.1 2 = 171.7mm. The distance L from the center of rotation of the horizontal worktable 9 to the end face of the front skirt 6.1 3 = 3000mm. The length C=6600mm of special-purpose platform 5, the width E=1400mm of special-purpose platform 5, the thickness A=300mm of special-purpose platform 5, the distance from the tangent line of the inner arc surface of the support base 4.3 lower end of the special-purpose support 4 to the support base 4.3 lower end bottom surface B=120mm. The distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com