Hydrostatic pressure type numerical controlled surface grinder with horizontal spindle and rotary table

A surface grinder and static pressure technology, which is used in grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc. The effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

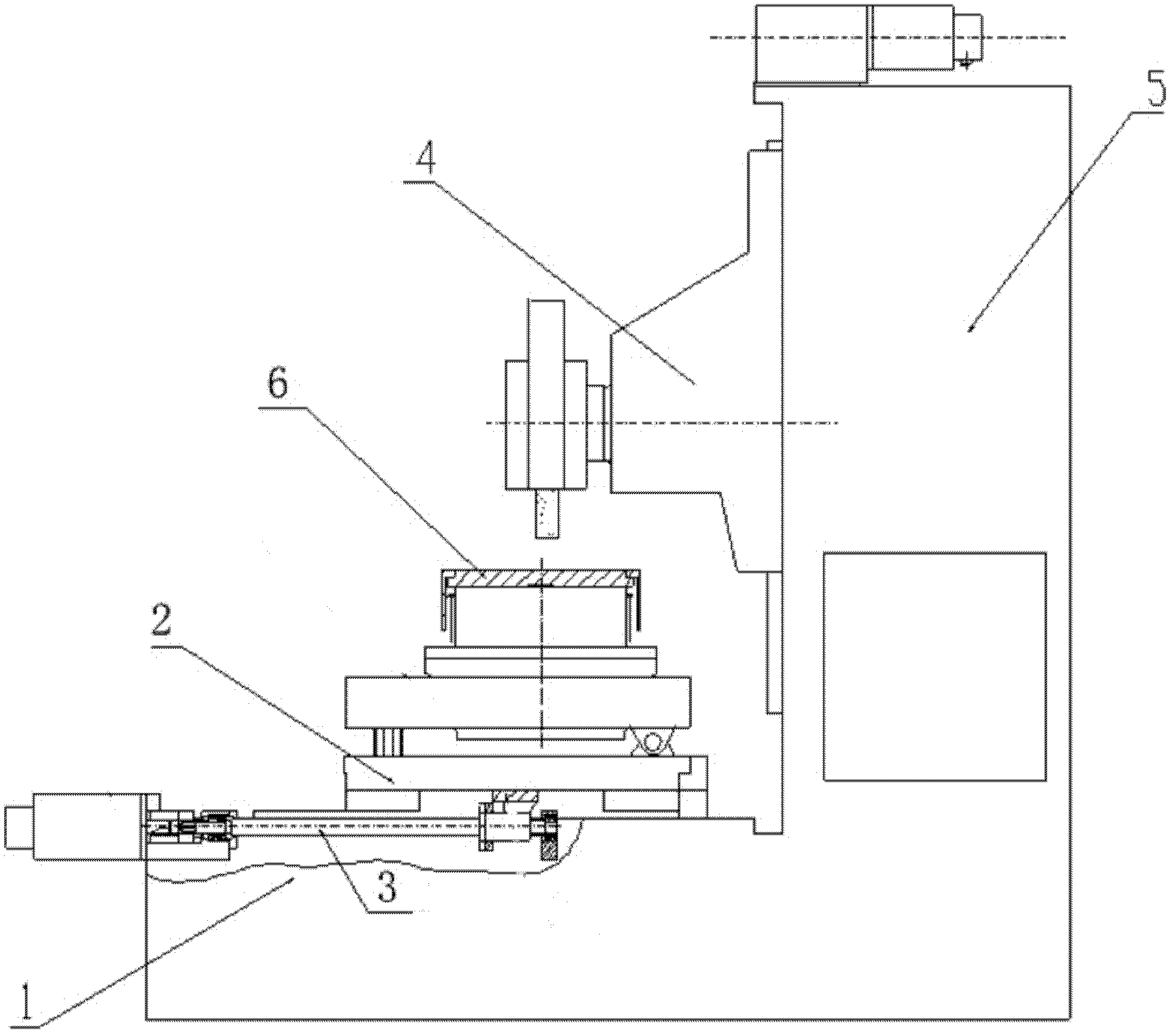

[0014] like figure 1 The hydrostatic CNC horizontal axis circular table surface grinder shown is mainly composed of a bed 1, a column 5, a table mechanism 2, a vertical feed mechanism, a grinding head mechanism 4, and a lateral feed mechanism 3, and the lateral feed mechanism 3 It is arranged on the bed 1, and the workbench mechanism 2 is fixed on the transverse feed structure 3; the vertical feed mechanism is installed on the upper end of the column 5, and is fixedly connected with the grinding head mechanism 4. The upper end of workbench mechanism is provided with sucker 6, vertical, and the side of 5 is also installed the operation box of control vertical feed mechanism, transverse feed mechanism 3 and workbench mechanism 2 motions.

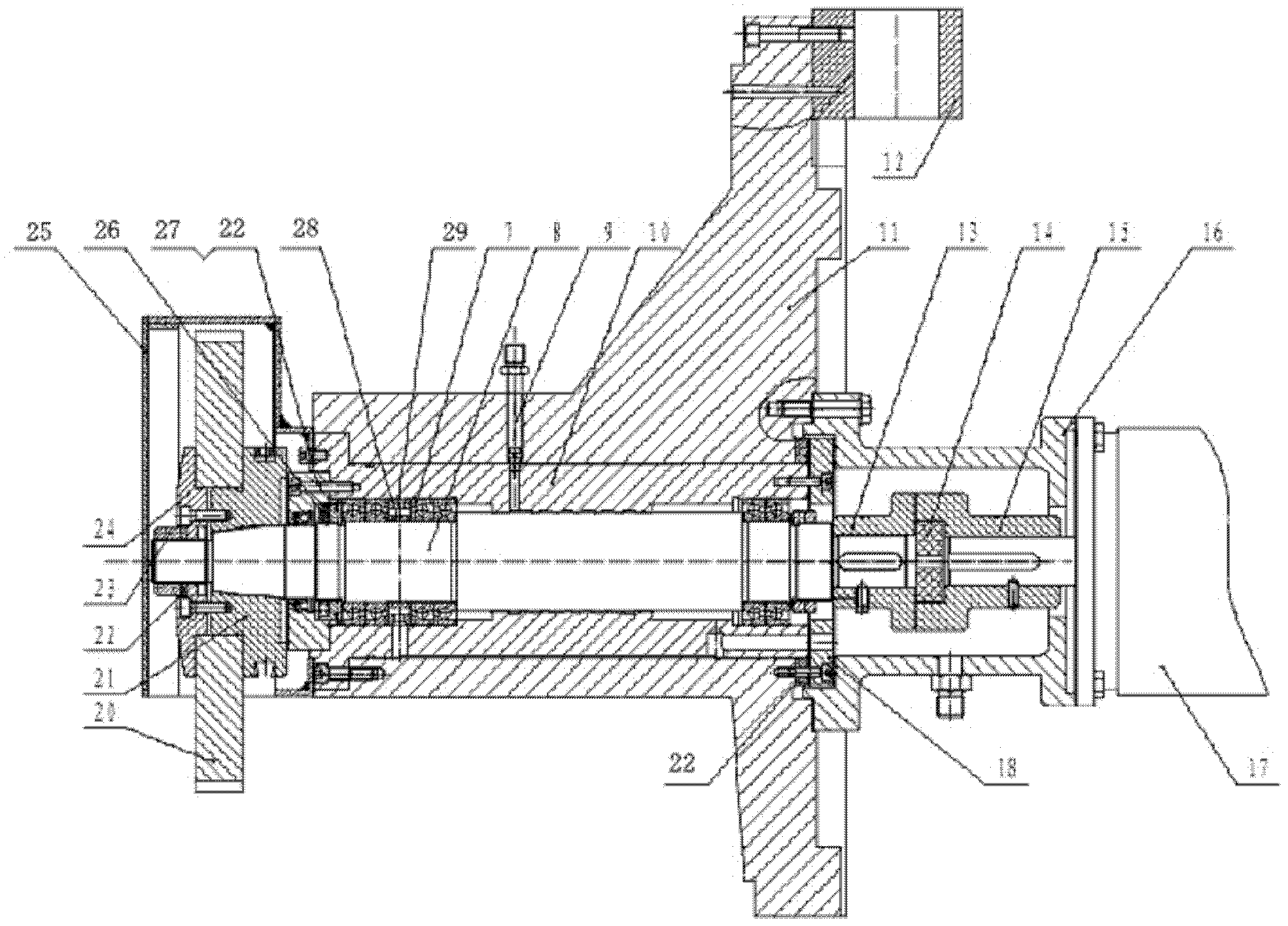

[0015] like figure 2 As shown, the grinding head mechanism includes a main shaft 8, a main shaft motor 17, a grinding wheel 20, a grinding wheel positioning plate 21, a grinding wheel pressing plate 24, a grinding wheel cover 25, and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com