System for continually mixing, modifying and pelletizing dewatered sludge

A technology for dewatering sludge and granulation, which is applied in dewatering/drying/concentrating sludge treatment, water/sludge/sewage treatment, sludge treatment, etc. The problem of low strength, etc., can increase the surface area of water loss, avoid secondary pollution, and achieve the effect of low water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

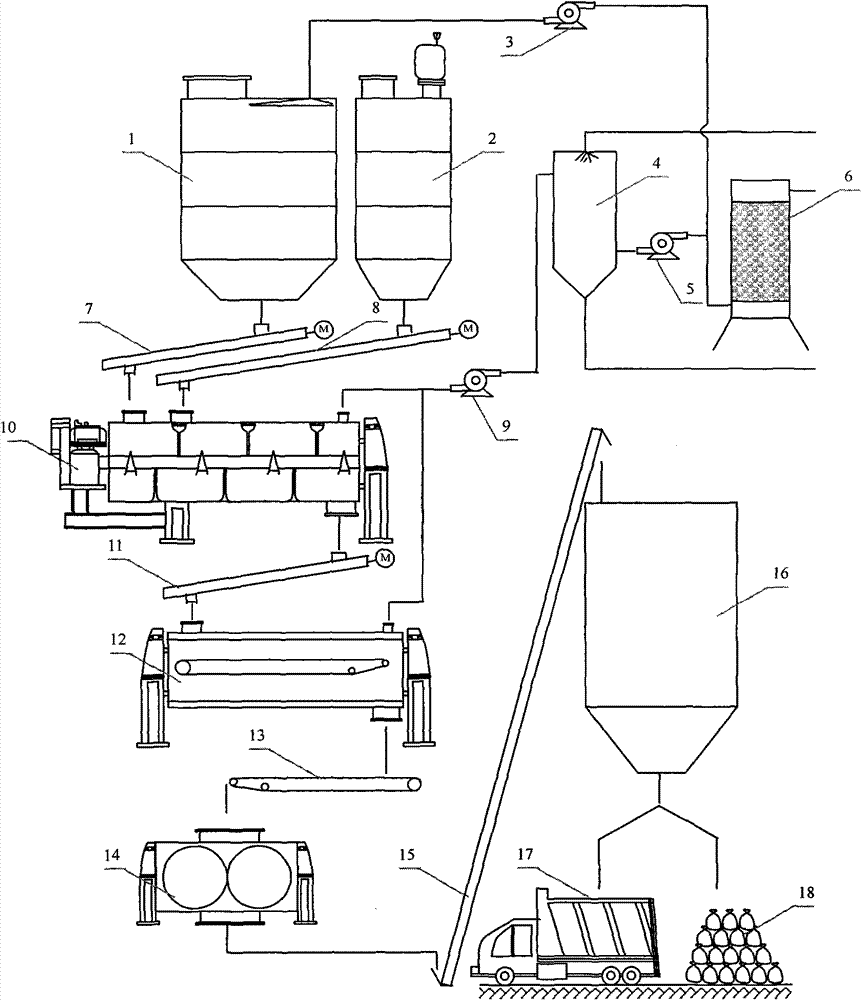

[0011] The following is a detailed description of a dewatered sludge continuous homogenization modified granulation system of the present invention in conjunction with the accompanying drawings: see the accompanying drawings

[0012] A continuous uniform mixing modified granulation system for dewatered sludge. The granulation system consists of a sludge silo 1, an auxiliary silo 2, a first screw metering pump 7, a second screw metering pump 8, a powerful homogeneous mixer 10, and an enhanced Equipment 12, sludge granulator 14, bucket elevator 15, dust removal tower 4, gas purification device 6, screw conveyor 11 and conveyor belt 13, the inlet of the first screw metering pump 7 and the outlet of the sludge silo 1 Pipeline connection, the outlet of the first screw metering pump 7 is connected to the sludge feed port on the strong homogeneous mixer 10, the inlet of the second screw metering pump 8 is connected to the outlet of the auxiliary silo 2, and the second screw metering p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com