Flat metal particle-containing composition and heat ray-shielding material

A technology of heat ray shielding and flat metal, applied in metal processing equipment, nanotechnology for materials and surface science, transportation and packaging, etc., can solve problems such as unstable light resistance of plasmonic polaritons, and achieve avoidance of decline, The effect of good transmittance and extreme transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

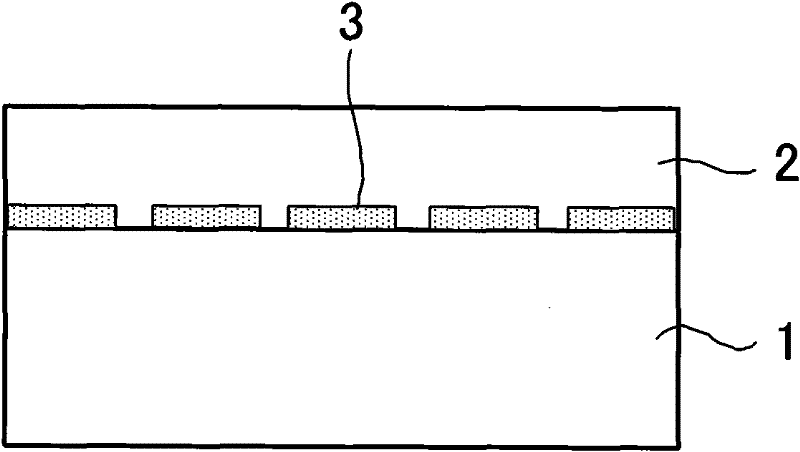

[0144] The production method of the heat ray shielding material of the present invention is not particularly limited, and may be appropriately selected depending on the intended purpose. In one available method, a substrate is coated with a dispersion comprising flat metal particles using, for example, a dip coater, slit coater, slit coater, rod coater, or gravure coater. In another embodiment, flat metal particles are plane-oriented by methods such as LB film method, self-organization method and spraying method.

[0145] Furthermore, a method utilizing electrostatic interaction to increase the adsorbability or plane orientation of the flat metal particles on the surface of the substrate can be applied to the plane orientation. Specifically, when the surface of the flat metal particles is negatively charged (for example, when the flat metal particles are dispersed in a medium that can be negatively charged, such as citric acid), the surface of the substrate is positively charg...

Embodiment

[0154] The present invention will be described below by way of examples, which should not be construed as limiting the present invention thereto.

[0155] The silver interaction potential EAg of the heterocyclic compounds used in Examples and Comparative Examples was determined as follows.

[0156]

[0157] The silver interaction potential EAg can be measured by the following silver interaction electromotive force method.

[0158] First, a solution (50 mL) containing a heterocyclic compound at a concentration of 0.00100M, potassium hydrogencarbonate at a concentration of 0.0200M, and potassium carbonate at a concentration of 0.0267M was prepared. The pH of the prepared solution was adjusted to 10.0 with 1M nitric acid or sodium hydroxide. Then, 1 mL of 0.00500 M silver nitrate was added to the resulting solution under magnetic stirring at 20°C-25°C. The potential of the solution at 15 min after silver nitrate addition was determined electrochemically using a calomel electr...

preparation Embodiment 1

[0160] -Synthesis of Flat Silver Particles-

[0161] A 0.5 g / L polystyrenesulfonic acid aqueous solution (2.5 mL) was added to a 2.5 mM sodium citrate aqueous solution (50 mL), followed by heating to 35°C. Then, to the resulting solution was added 10 mM sodium borohydride solution (3 mL). Then 0.5 mM silver nitrate aqueous solution (50 mL) was added thereto at 20 mL / min with stirring. The solution was stirred for 30 min to prepare a seed solution (synthetic step of flat nuclei).

[0162] Then, ion-exchanged water (87.1 mL) was added to a 2.5 mM sodium citrate aqueous solution (132.7 mL), followed by heating to 35°C. Subsequently, 10 mM ascorbic acid aqueous solution (2 mL) was added to the resulting solution, and then 42.4 mL of the seed crystal solution prepared above was added thereto. Subsequently, a 0.5 mM silver nitrate aqueous solution (79.6 mL) was added thereto at 10 mL / min with stirring (first growth step of flat particles).

[0163] Then, the solution obtained ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com