Method for deeply desulfurizing oil based on low viscosity ionic liquid

An ionic liquid and deep desulfurization technology, which is applied in the field of removing sulfur-containing compounds in oil products in the petrochemical field, can solve the problems of reducing the mass transfer rate in the extraction process, reducing the extraction amount, and high viscosity, achieving good reusability, The effect of mild desulfurization conditions and fast desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

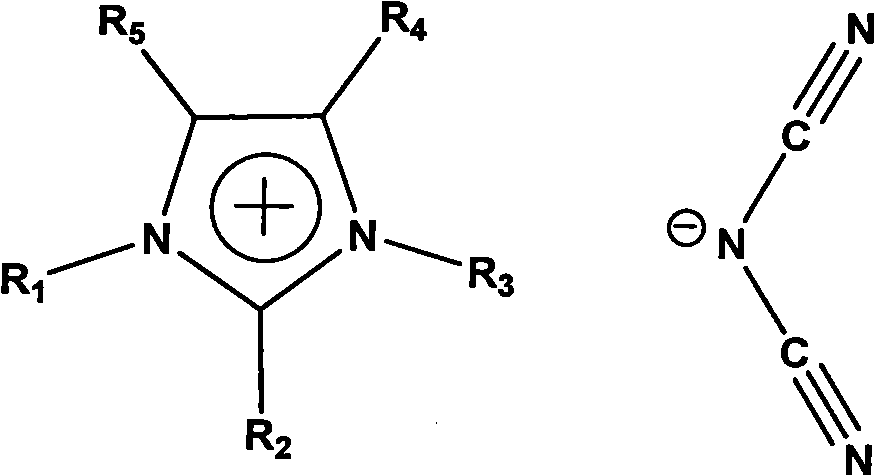

[0014] 3g[C 2 mim][dca](1-ethyl-3-methylimidazolium dicyanamide salt), added to 3g of simulated gasoline containing about 500ppm of sulfur (thiophene), stirred at 298K for 20min under normal pressure, and left to stand , layered, and detected by high-performance liquid chromatography, the sulfur content in the oil can be reduced to below 300ppm, and the desulfurization rate of a single extraction is as high as 40%. After the extraction and separation, separate the ionic liquid phase, dilute the ionic liquid phase with water, filter, distill the filtrate under reduced pressure at 80°C, and then vacuum dry at 80°C to obtain a regenerated ionic liquid, which can be reused.

Embodiment 2

[0016] 3g[C 2 mim][dca](1-ethyl-3-methylimidazolium dicyanamide salt), added to 3g simulated diesel oil containing sulfur (dibenzothiophene) about 500ppm, stirred at 298K for 20min under normal pressure , stand still, layered, and detected by high-performance liquid chromatography, the sulfur content in the oil can be reduced to below 230ppm, and the desulfurization rate of a single extraction is as high as 54%. After the extraction and separation, separate the ionic liquid phase, dilute the ionic liquid phase with water, filter, distill the filtrate under reduced pressure at 80°C, and then vacuum dry at 80°C to obtain a regenerated ionic liquid, which can be reused.

Embodiment 3

[0018] 3g[C 4 mim][dca](1-butyl-3-methylimidazolium dicyanamide salt), added to 3g of simulated gasoline containing about 500ppm sulfur (thiophene), stirred at 298K for 20min under normal pressure, and then left to stand , layered, and detected by high-performance liquid chromatography, the sulfur content in the oil can be reduced to below 210ppm, and the desulfurization rate of a single extraction is as high as 58%. After the extraction and separation, separate the ionic liquid phase, dilute the ionic liquid phase with water, filter, distill the filtrate under reduced pressure at 80°C, and then vacuum dry at 80°C to obtain a regenerated ionic liquid, which can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com