Control method for reducing oil consumption of excavator engine

A control method and engine technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of increased system pressure and flow demand, unsuitable for promotion and use, and energy waste, so as to reduce failure rate and shorten production The effect of speed reduction and fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with principle diagrams and specific operation examples.

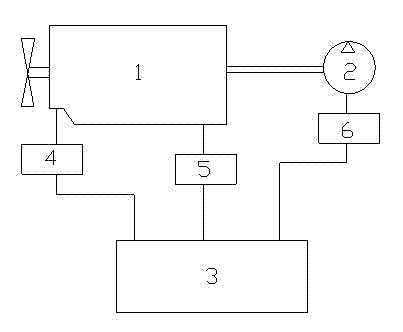

[0026] Such as figure 1 As shown, the control method for reducing the oil consumption of excavator engine in the present invention is realized on the basis of the power mechanism and control device of the existing hydraulic excavator. The power mechanism specifically includes engine 1 and main pump 2, and engine 1 drives main pump 2 Rotate, the control device is the system controller CPU3, the CPU3 is connected to the engine 1 through the speed sensor 4 and the throttle 5 respectively, and the CPU3 is also connected to the hydraulic pump 2 through the pressure sensor 6.

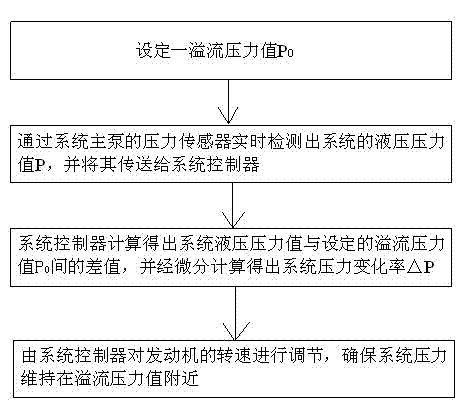

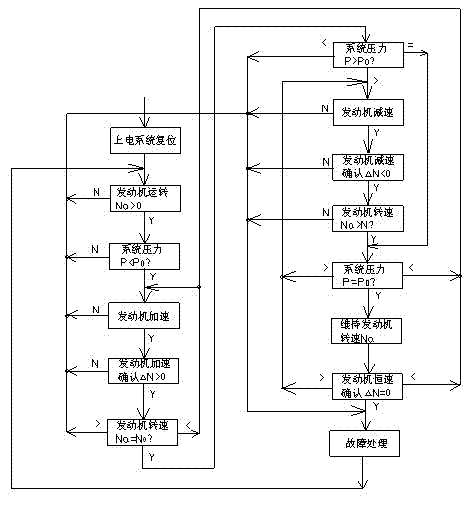

[0027] Such as figure 2 As shown, the control method of the present invention to reduce the fuel consumption of the excavator engine specifically includes: setting a relief pressure value P 0 ;The pressure sensor 6 of the main pump 2 of the system detects the hydraulic pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com