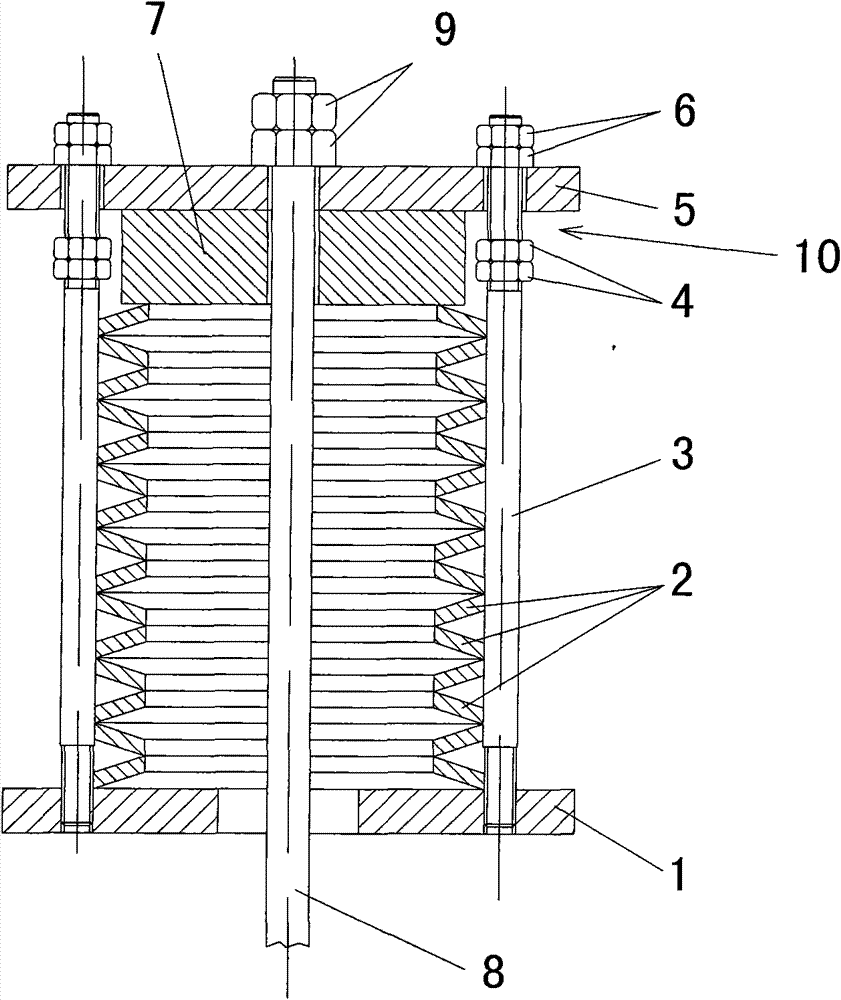

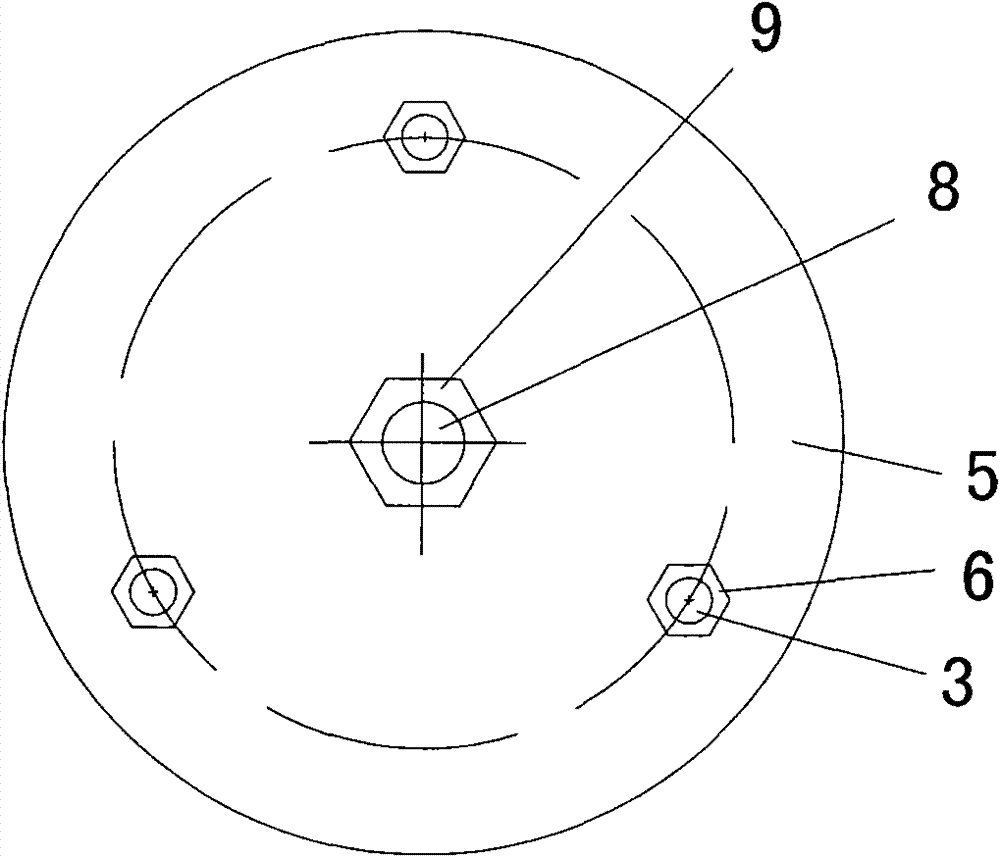

Disk spring hanger with three guide posts and limiting function

A disc spring and functional technology, applied in the field of variable disc spring support and hanger, can solve the problems of large amount of material consumption, large processing amount, test influence, etc., and achieve the effect of simple overall structure, reduced material cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Such as figure 1 , 2 Shown: 1 is base plate, 5 is pressing plate, and base plate 1 and pressing plate 5 are all disc shapes. 3 is a guide column, and the lower end of the guide column 3 is threaded and connected with the threaded hole on the base plate 1. The top of guide column 3 penetrates in the hole on the pressure plate 5 and the upper end protrudes upwards, and the upper end of guide column 3 is threaded with guide column nut 6, and guide column nut 6 is a double nut and back-tightened mutually. There are three guide columns 3, which are evenly distributed in the circumferential direction. On each guide post 3, the limit nut 4 is threadedly connected under the pressure plate 5, and the limit nut 4 is a double nut and back-tightened to each other. During normal operation, turn down the limit nut 4 to leave a gap 10 between it and the pressing plate 5 . The height of the gap 10 is the maximum displacement of the pressing plate 5 when stressed. Pull rod 8 is pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com