Full-process automatic control system for supercritical unit water supply system

A technology of automatic control system and supercritical unit, which is applied in the control of water supply, preheating, steam generation, etc., can solve the problems of large influence of water supply, low safety, adverse consequences, etc., so as to reduce human misoperation and improve operation. Efficiency, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

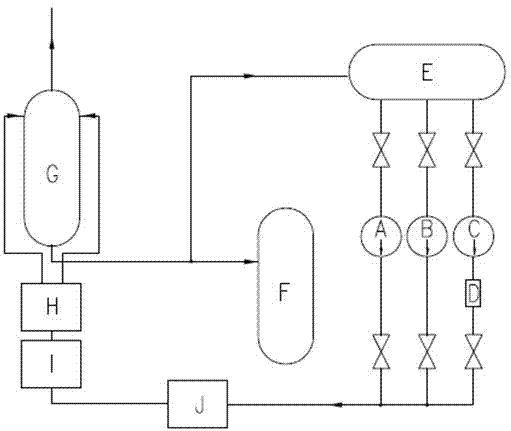

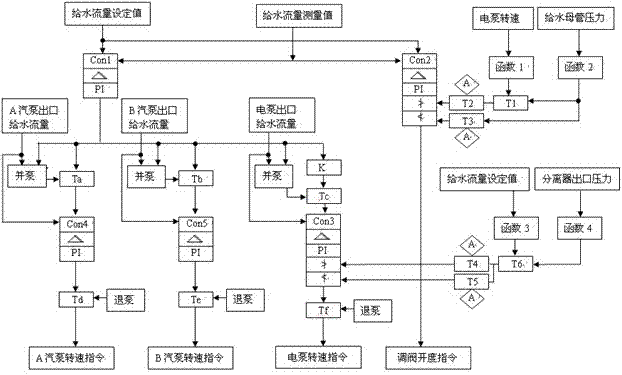

[0035] The whole process automatic control system of a supercritical unit water supply system provided by the present invention is based on such figure 1 The water supply system configuration of a typical 600MW supercritical unit shown includes an electric pump C with a regulating valve D at the outlet, the first steam-driven feed water pump A and the second steam-driven water feed pump B, the electric pump C, the first steam-driven water pump One end of the feedwater pump A and the second steam-driven feedwater pump B are respectively connected to the deaerator E, and the other end is connected to the high-speed generator J at the same time, and the high-power generator J is connected in series with the economizer I and the water wall H, and the water wall H is connected to the steam-water separator G. The steam-water separator G is connected to the boiler drain expander F, and the boiler drain expander F is connected to the deaerator E.

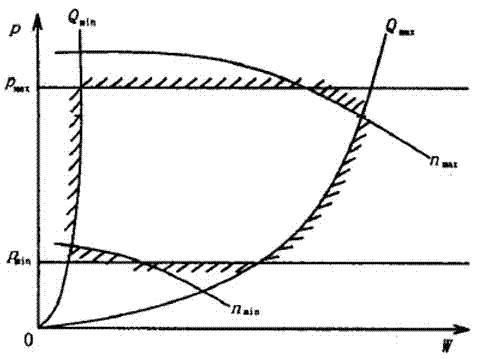

[0036] The basis for the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com