Micro sound pressure sensor with bionic cricket cilia structure and manufacturing method thereof

A sound pressure sensor and micro-imitation technology, applied in instruments, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problems of low rigidity and low sensitivity of ciliary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Specific implementation method

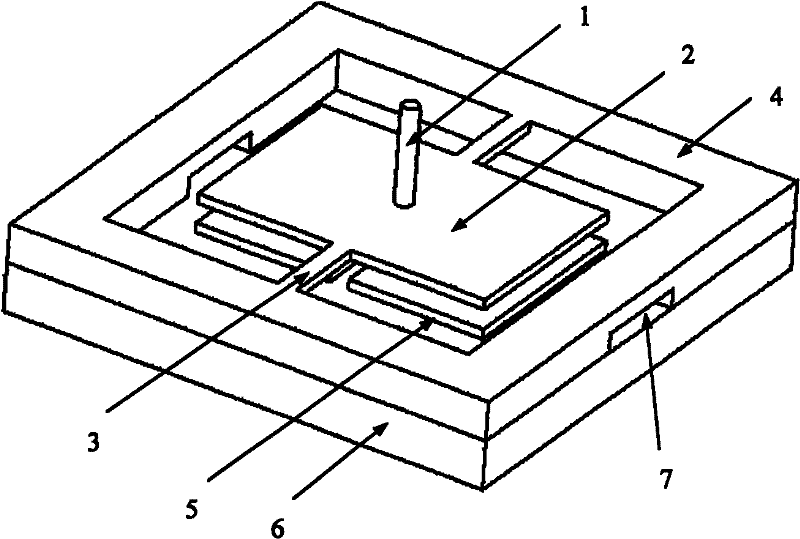

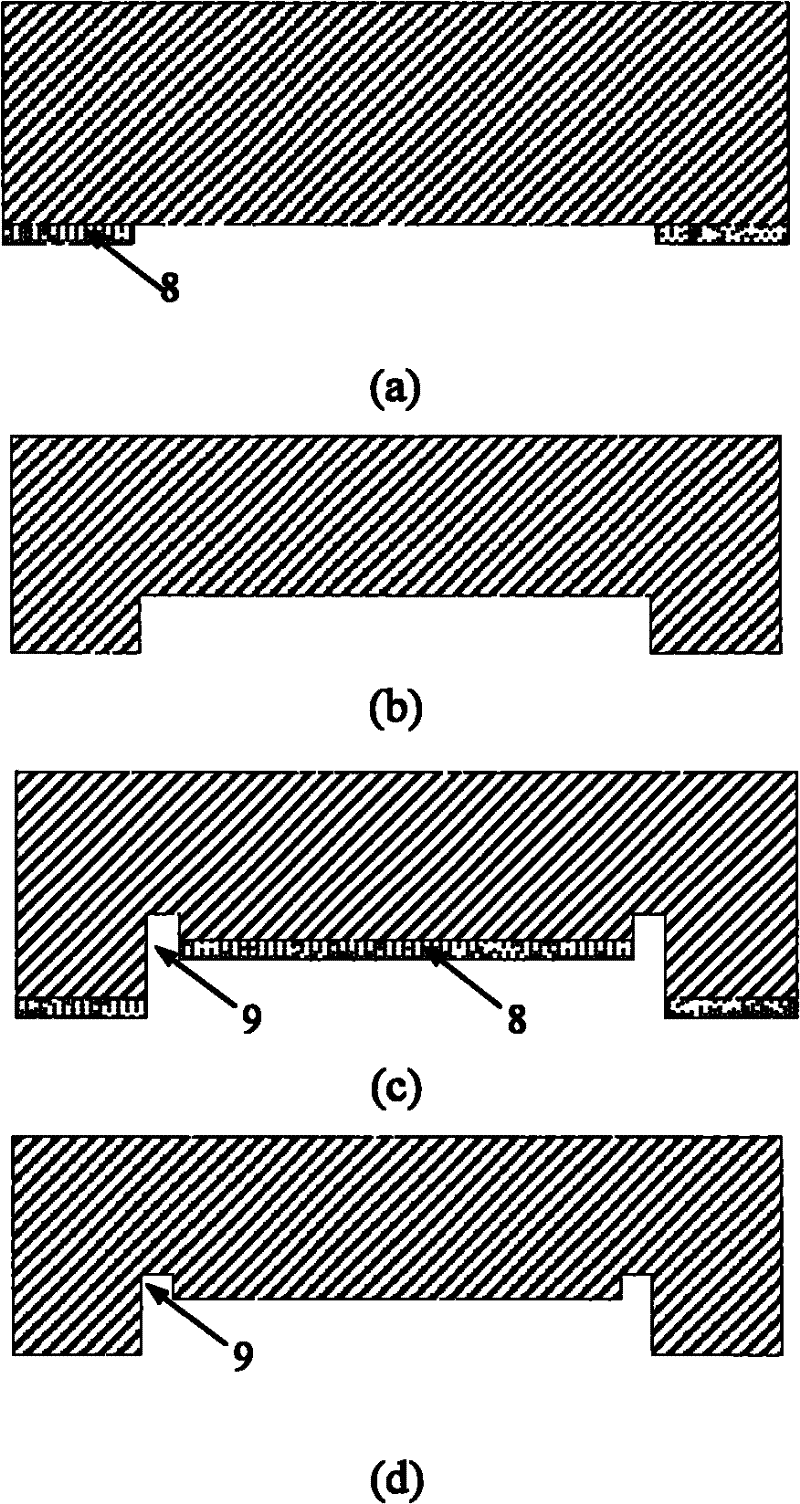

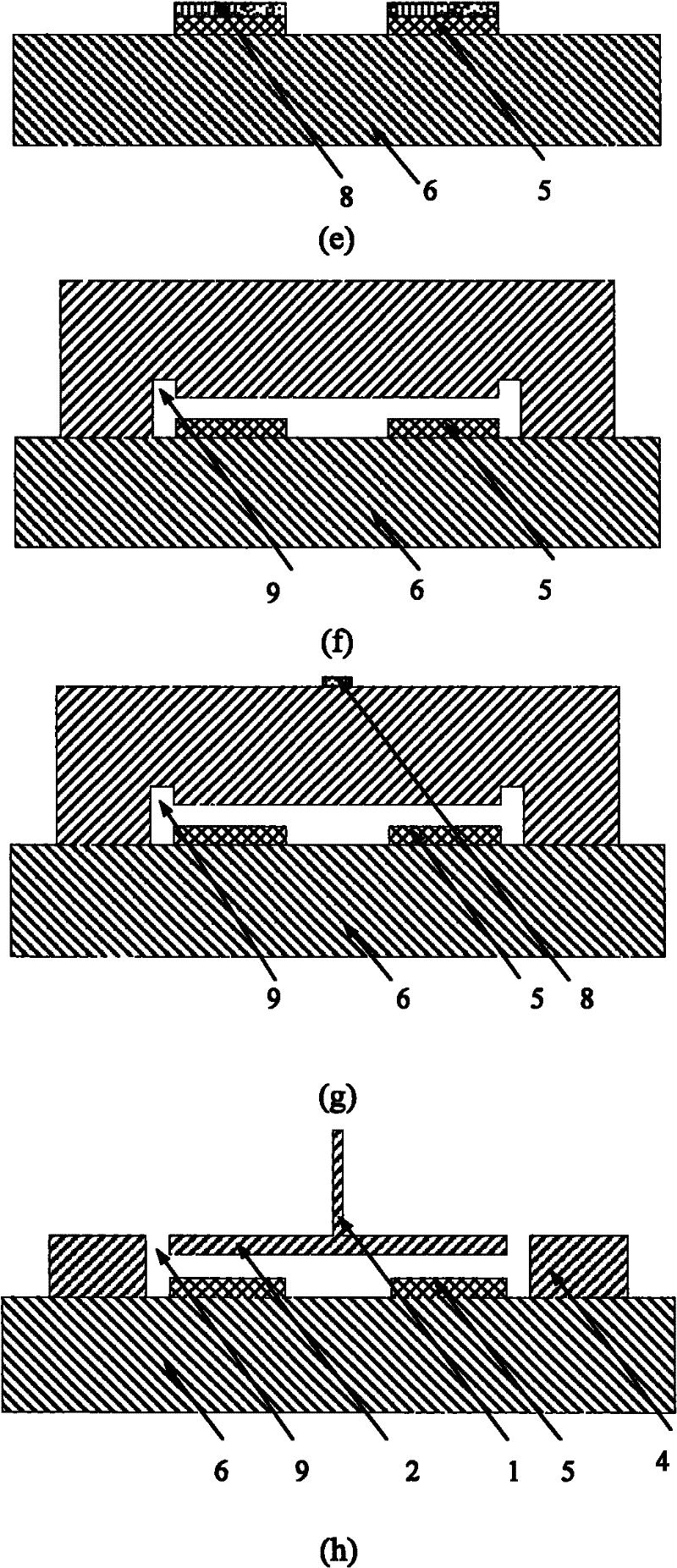

[0021] Refer to figure 1 The miniature cricket-like cilia structure sound pressure sensor in this embodiment includes a cricket-like cilia structure 1, a sensitive diaphragm 2, a supporting beam 3, a fixing structure 4, two detection electrodes 5, and a glass substrate 6; a cricket-like cilia structure 1 Located above the sensitive diaphragm 2 and connected to it as a whole, the cricket cilia structure 1 has a diameter of 500nm and a length of 10μm; the sensitive diaphragm 2 is connected to the annular fixed structure 4 through two supporting beams 3, and the sensitive diaphragm There is a 20μm gap 9 between 2 and the ring-shaped fixed structure 4; the ring-shaped fixed structure 4 is anodically bonded to the glass substrate 6 sputtered with two detection electrodes 5, so that a certain gap is passed between the sensitive diaphragm 2 and the two detection electrodes 5 A flat capacitor structure is formed to detect the vibration displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com