Shock device and safety cap shock test machine

An impact device and impact testing technology, applied in the field of impact devices, can solve problems such as unsatisfactory objects falling and impacting, worker injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

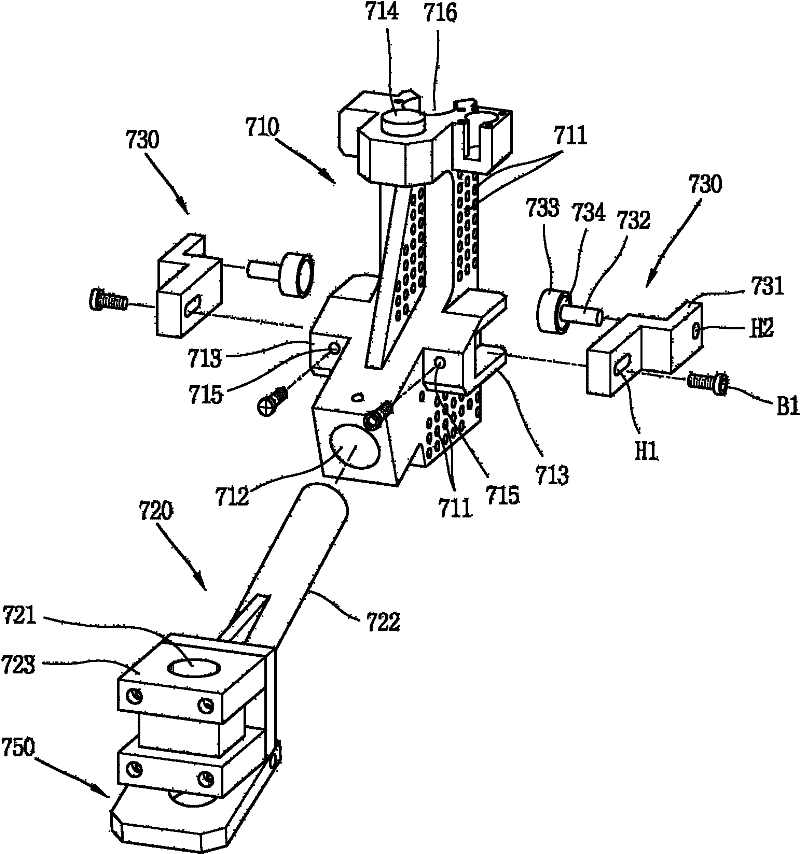

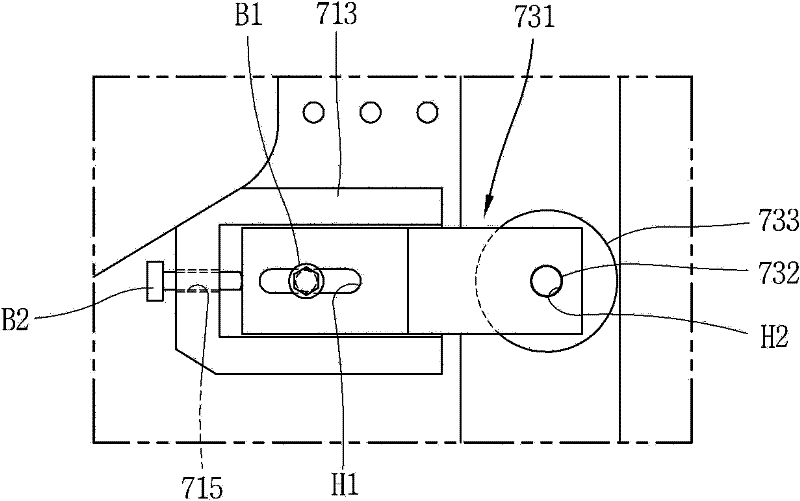

[0019] Referring to the accompanying drawings, embodiments of an impact device according to the present invention and a helmet impact testing apparatus having the same will now be described.

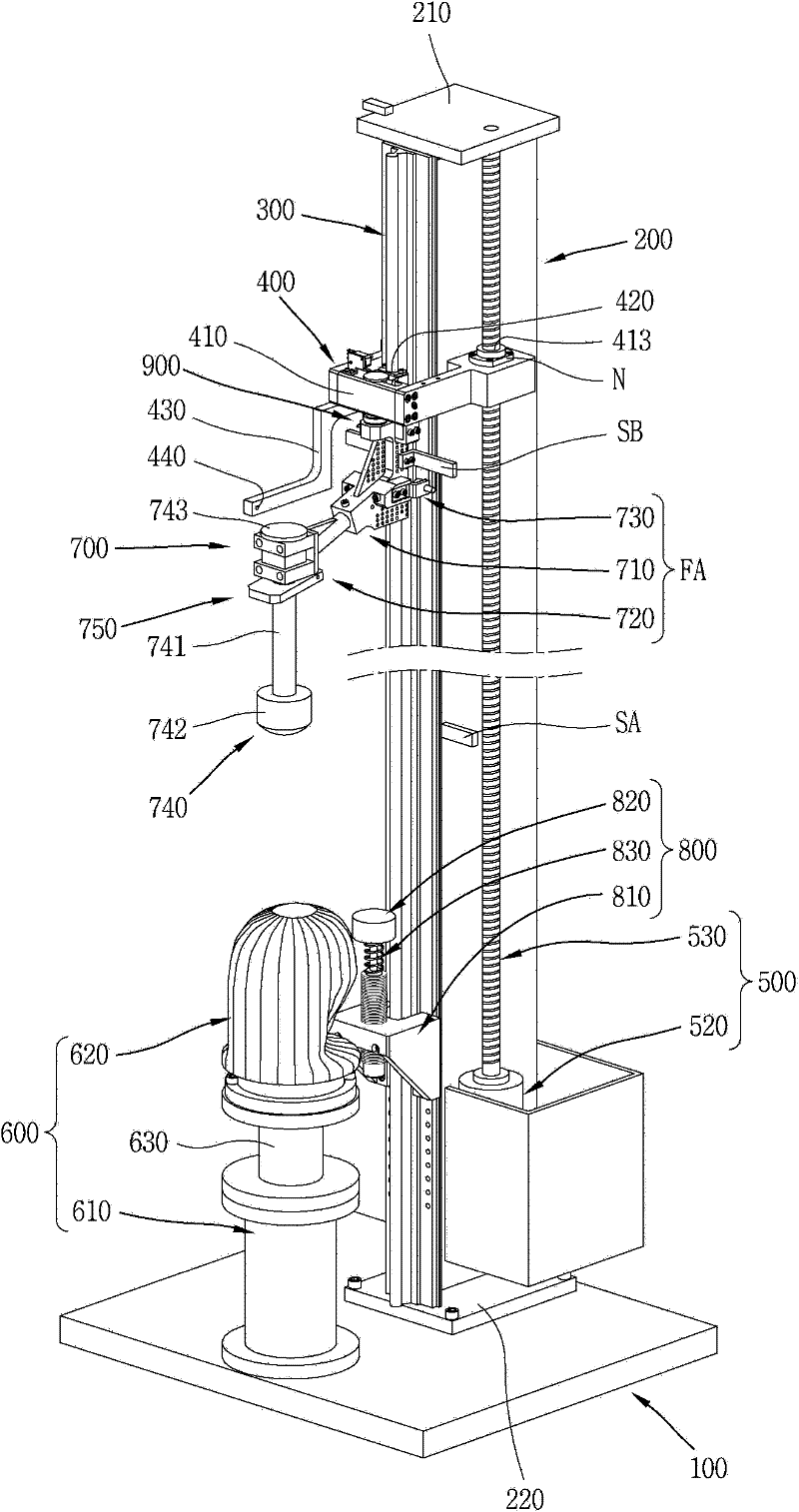

[0020] figure 1 is a perspective view of one embodiment of an impact device according to the present invention and a helmet impact testing apparatus having the same.

[0021] Such as figure 1 As shown, the safety helmet impact testing equipment according to an example of the present invention includes a base 100, a guide frame 200, a moving part 400, a drive unit 500, a test object support unit 600, an impact device 700, a position-fixed buffer 800, connectable / The detachable unit 900 and the sensing unit.

[0022] The base 100 has a constant thickness and a predetermined area. The base 100 may be formed in a square shape in a plan view of the base 100 .

[0023] The guide frame 200 has a predetermined length, and may be formed in a shape of 'I' in a cross-sectional view of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com