Tightening device communicated with multiple osmometers

A technology of fastening device and osmometer, applied in measuring device, using stable tension/pressure test material strength, instrument and other directions, can solve the problems of low work efficiency, large compression ratio, difficult exhaust, etc. The effect of working efficiency, preventing oil leakage and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

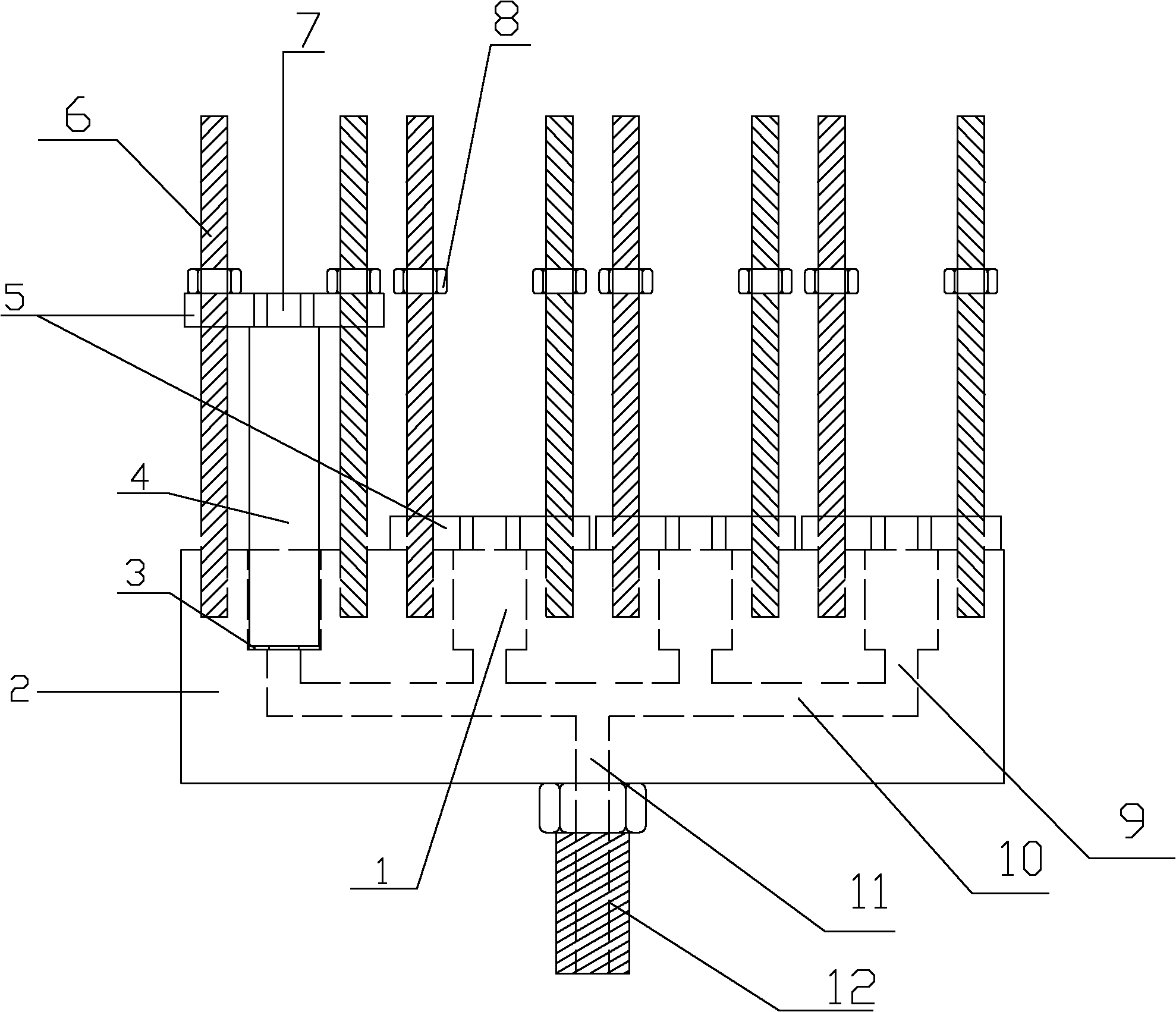

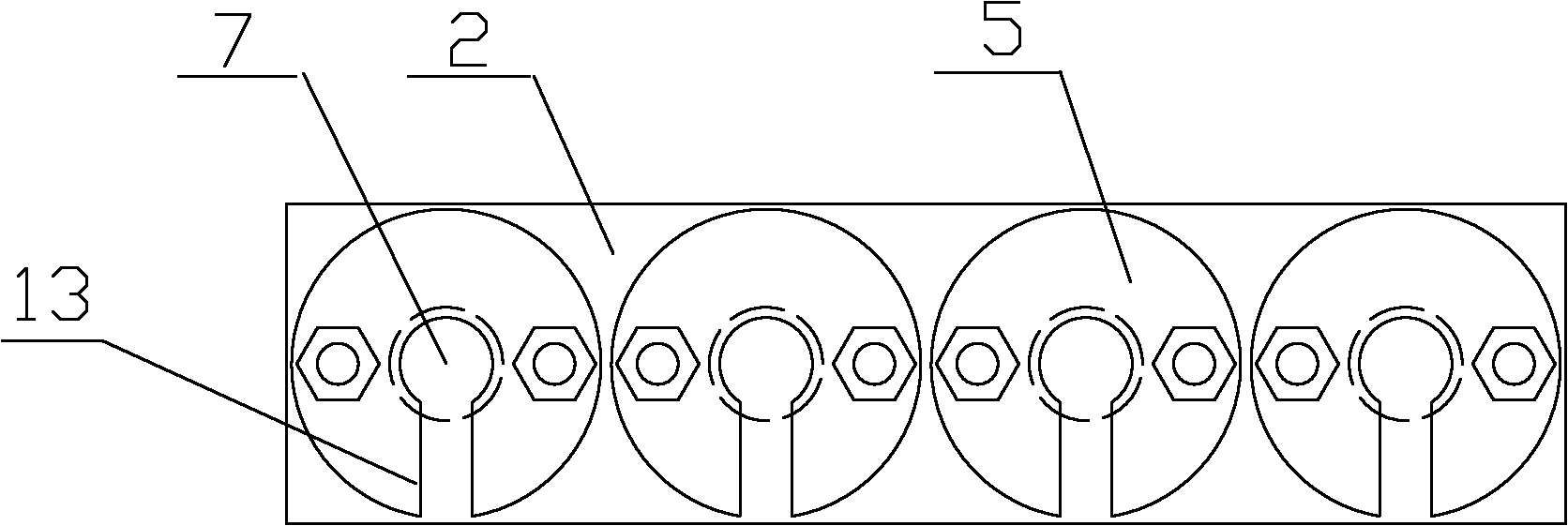

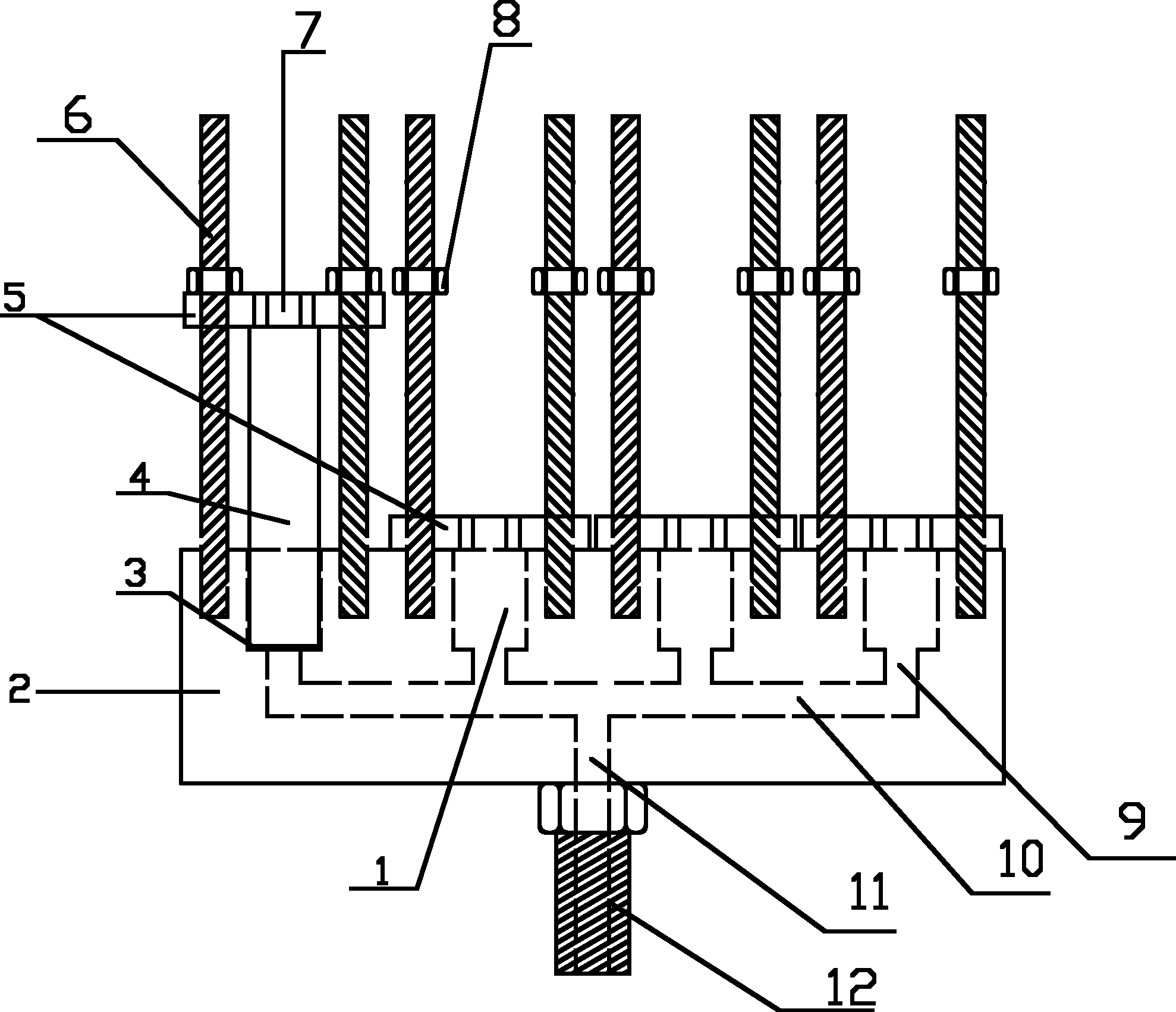

[0015] See figure 1 , figure 2 , The present invention has a base 2, on which a piezometer hole 1 is opened, the lower part of the base 2 is connected with a pressure device, and the pressure device has a pressure pipe 11 leading into the piezometer hole 1. The key technology is that there is more than one piezometer hole 1 on the base 2, a polyurethane gasket 3 is provided at the bottom of the piezometer hole 1, and a hole is provided in the middle of the polyurethane gasket 3 to pressurize the piezometer. A pressurized pipe 11 is opened in the base 2, and the pressurized pipe 11 is connected to a connecting pipe 10. On the connecting pipe 10, there are branch pipes 9 which respectively lead to each piezometer hole 1. A cover plate 5 is provided above the piezometer hole 1. In the middle of the cover plate 5, there is an orifice 7 corresponding to the piezometer hole 1. On both sides of the orifice 7, there are screw holes, and the base 2 is located on both sides of the piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com