Method for designing vibrator structure of bell-shaped vibrator type angular rate gyro

A technology of angular rate gyroscope and bell-shaped vibrator, which is applied in the direction of speed measurement, calculation, steering sensing equipment, etc. of the gyro effect, and can solve the high cost of research and development of the bell-shaped vibrator angular rate gyro vibrator and the shortening of the bell-shaped vibrator angular rate gyroscope. Problems such as development time and shortening the design cycle of the bell-shaped vibrator can be achieved to improve the ability and accuracy of verification analysis, optimize the design scheme, and increase the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

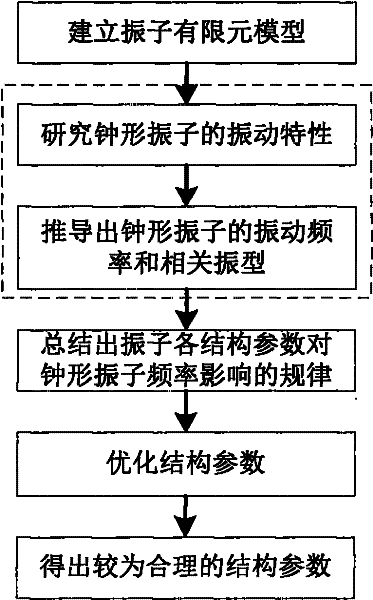

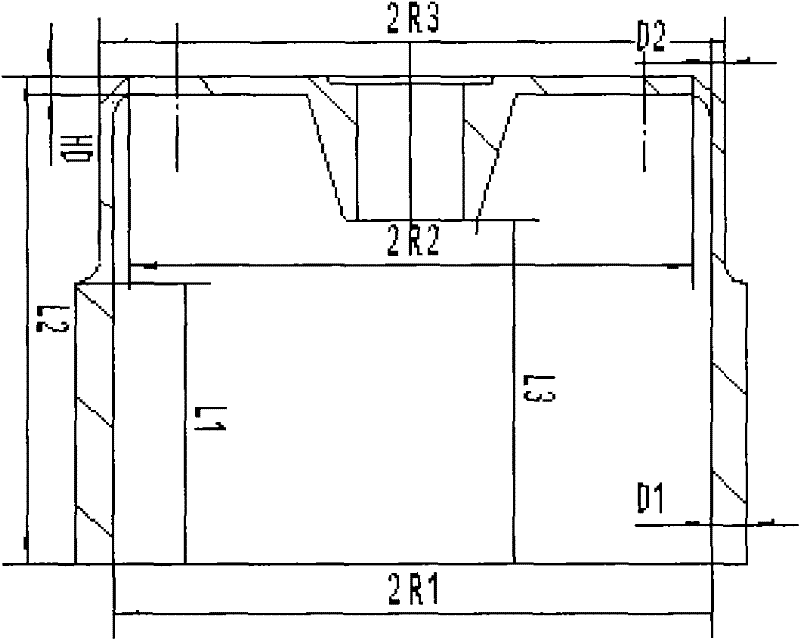

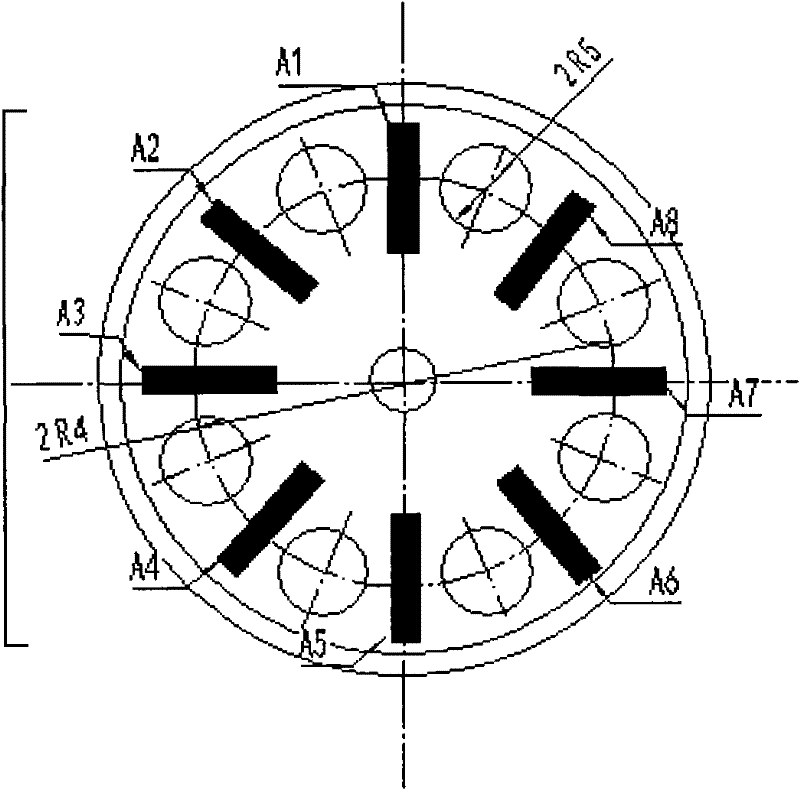

[0034] The principle of the bell-shaped oscillator type angular rate gyro is to use the precession of the mode shape angle caused by the rotation of the resonant bell-shaped oscillator to determine the rotation angle of the gyro base around the inertial space. In order for the bell-shaped vibrator to produce an ideal mode shape with a circular wavenumber n=2, the excitation frequency of the bell-shaped vibrator must be accurately controlled, and this frequency is exactly the natural frequency of the bell-shaped vibrator under this mode shape, so we It is necessary to rationally design the structure of the bell-shaped vibrator so that the obtained bell-shaped vibrator can produce an ideal mode shape.

[0035] According to the vibration theory, the natural frequency and mode shape of the bell-shaped vibrator are only related to the stiffness characteristics and mass distribution of the bell-shaped vibrator. Therefore, the natural frequency and mode shape of the bell-shaped vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com