Method and device for counting bar materials

A counting device and bar technology, applied in counting objects, counting of stacked items, counting mechanism/items, etc., can solve problems such as reliability decline, influence on alignment, deviation, etc., to reduce labor intensity and improve production efficiency , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

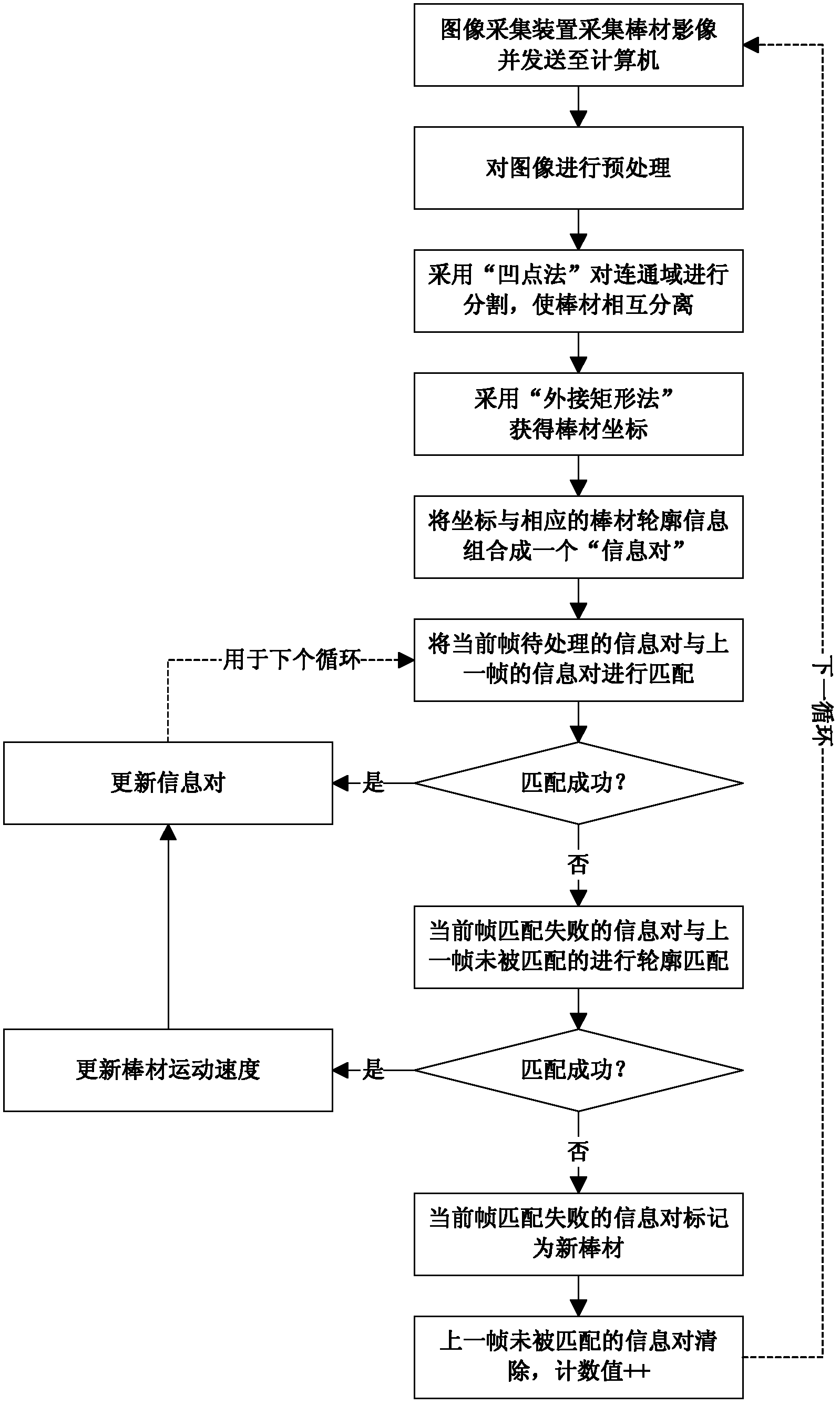

[0042] A method for counting rods, comprising the steps of:

[0043] The image acquisition device collects the image of the end face of the bar and sends it to the computer;

[0044] Preprocess the image;

[0045]The "concave point method" is used to segment the connected domain so that the rods are separated from each other. The connected domain refers to a collection composed of several pixels. The pixels in this collection have the following characteristics: the gray levels of all pixels are less than or equal to The level of the connected domain; the pixels in the same connected domain are connected in pairs, that is, there is a path completely composed of the elements of this set between any two pixels. Use the "concave point method" to accurately separate the end face image of the adjacent bar into individual bars, with high reliability; use the "circumscribed rectangle method" to obtain the bar coordinates, that is, the connected domain that has been cut into a single ...

Embodiment 2

[0059] A bar material counting device includes an illumination light source, an industrial camera, a computer and auxiliary parts.

[0060] The illumination light source 10 and the industrial camera 20 are arranged in the incident and reflection directions with the end face 40 of the bar to be processed as the reflecting surface, and the industrial camera 20 adopts an area array industrial camera with a frame rate of more than 30 frames;

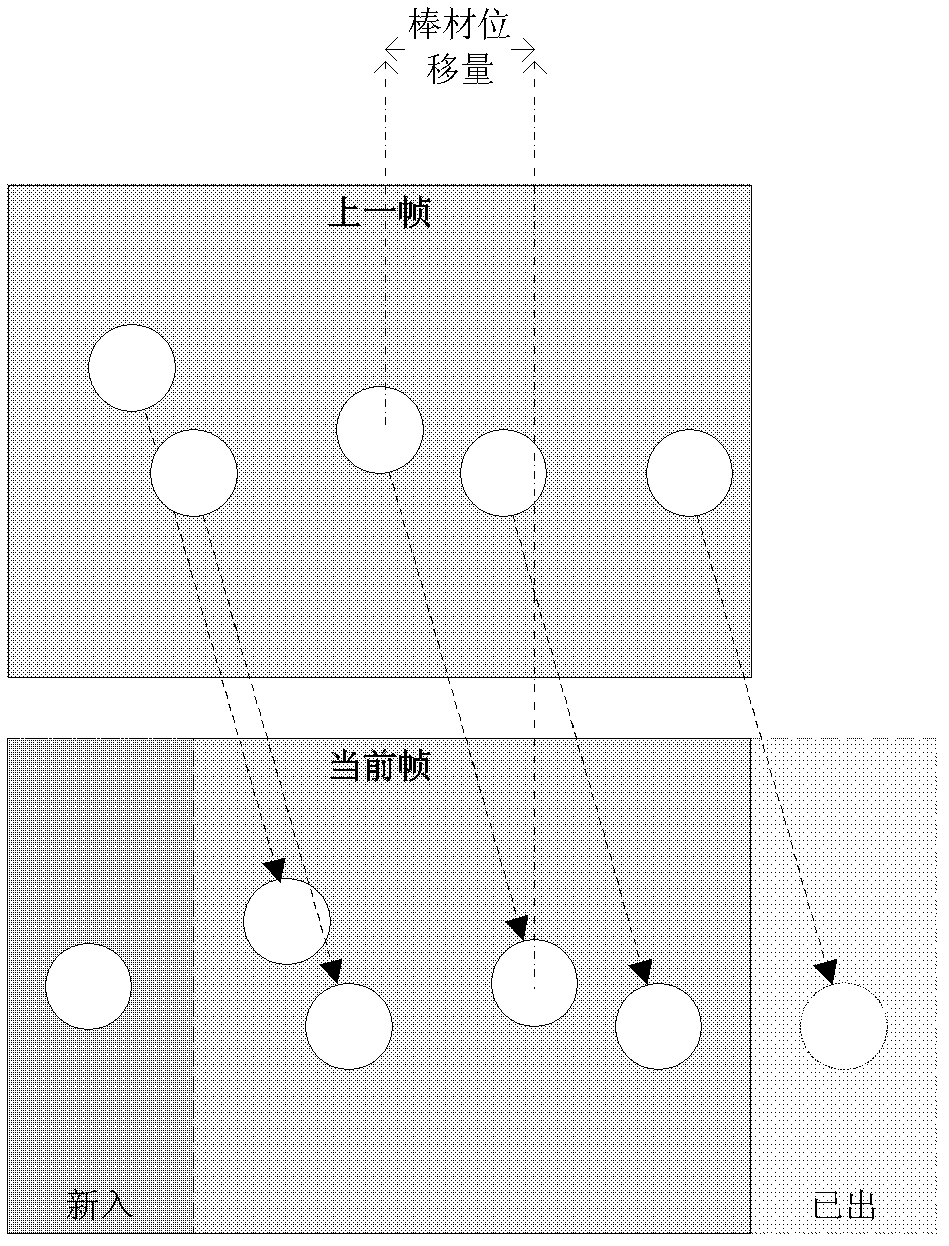

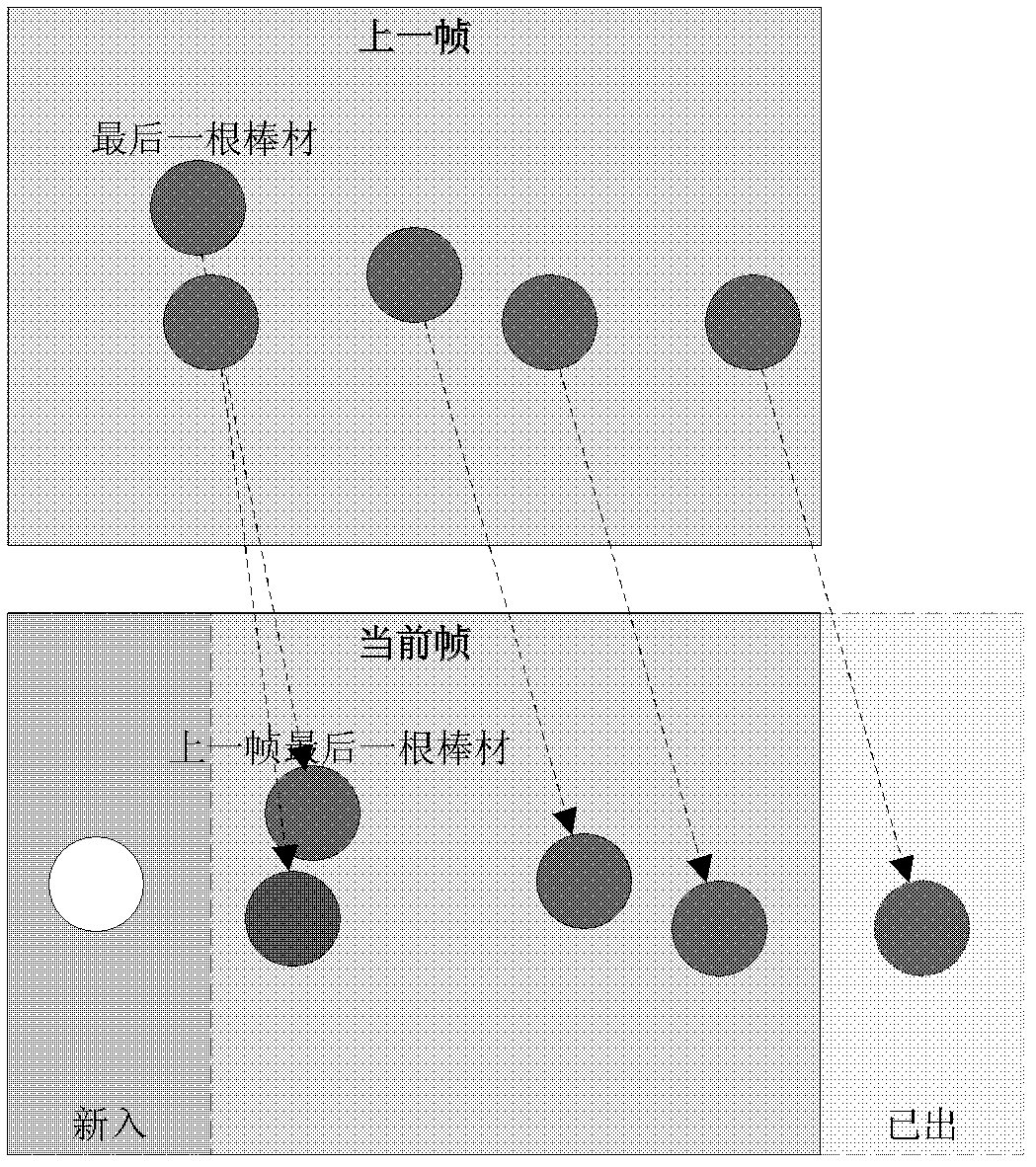

[0061] The computer 30 receives the image information collected by the industrial camera 20 and performs the following processing: preprocessing the image; using the "concave point method" to segment the connected domain so that the bars are separated from each other; using the "circumscribed rectangle method" to obtain the bar Material coordinates; combine the coordinates and the corresponding bar profile information into an "information pair"; match and count the information pairs to be processed in the current frame with the information pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com