Hollow light-emitting diode (LED) display screen

A hollow-out LED display technology, which is applied in the field of hollow-out LED displays, can solve problems such as loud noise and resonance of fans or air conditioners, building damage, and dust accumulation, so as to improve assembly efficiency, reduce the number of uses, and prolong the use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

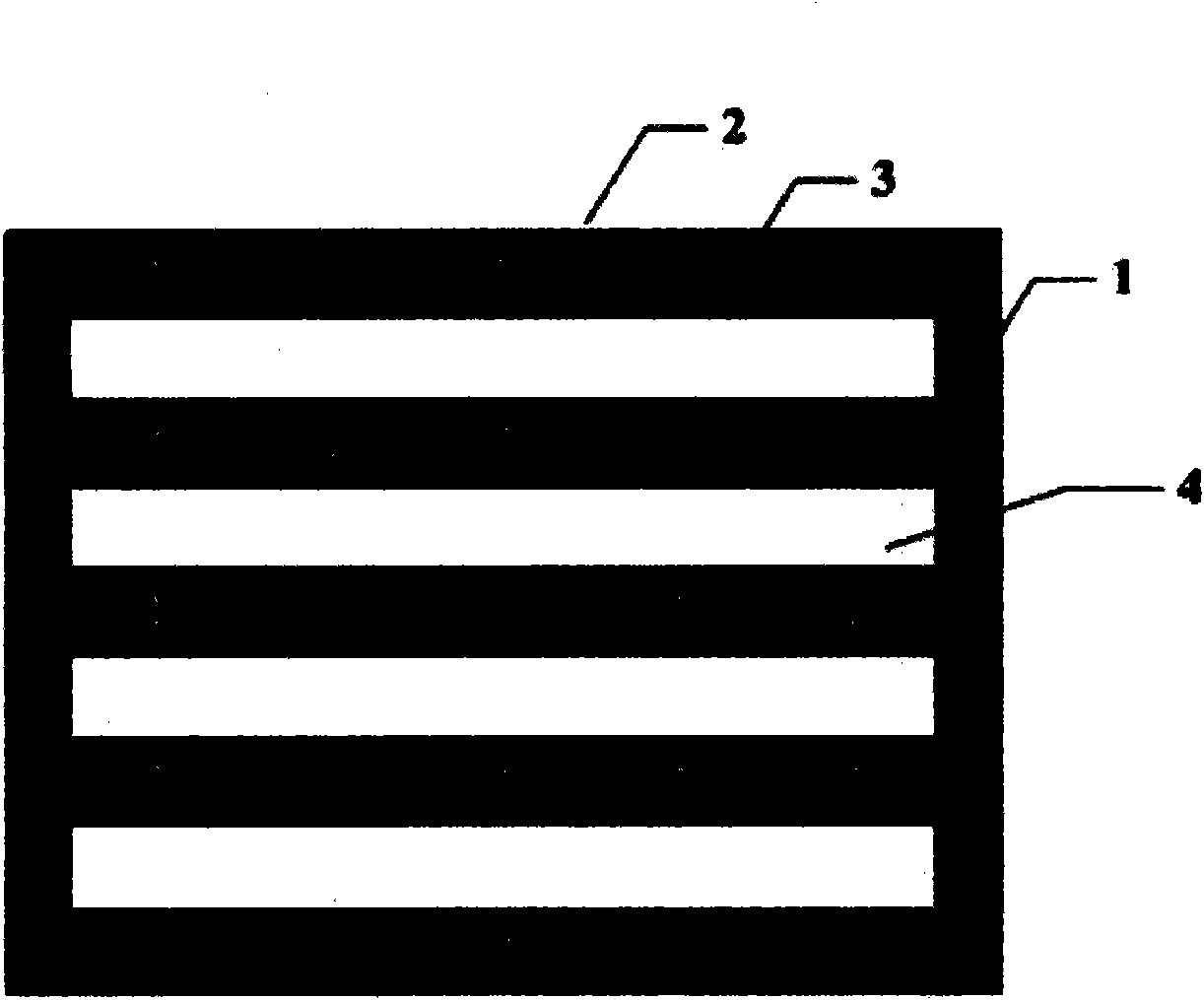

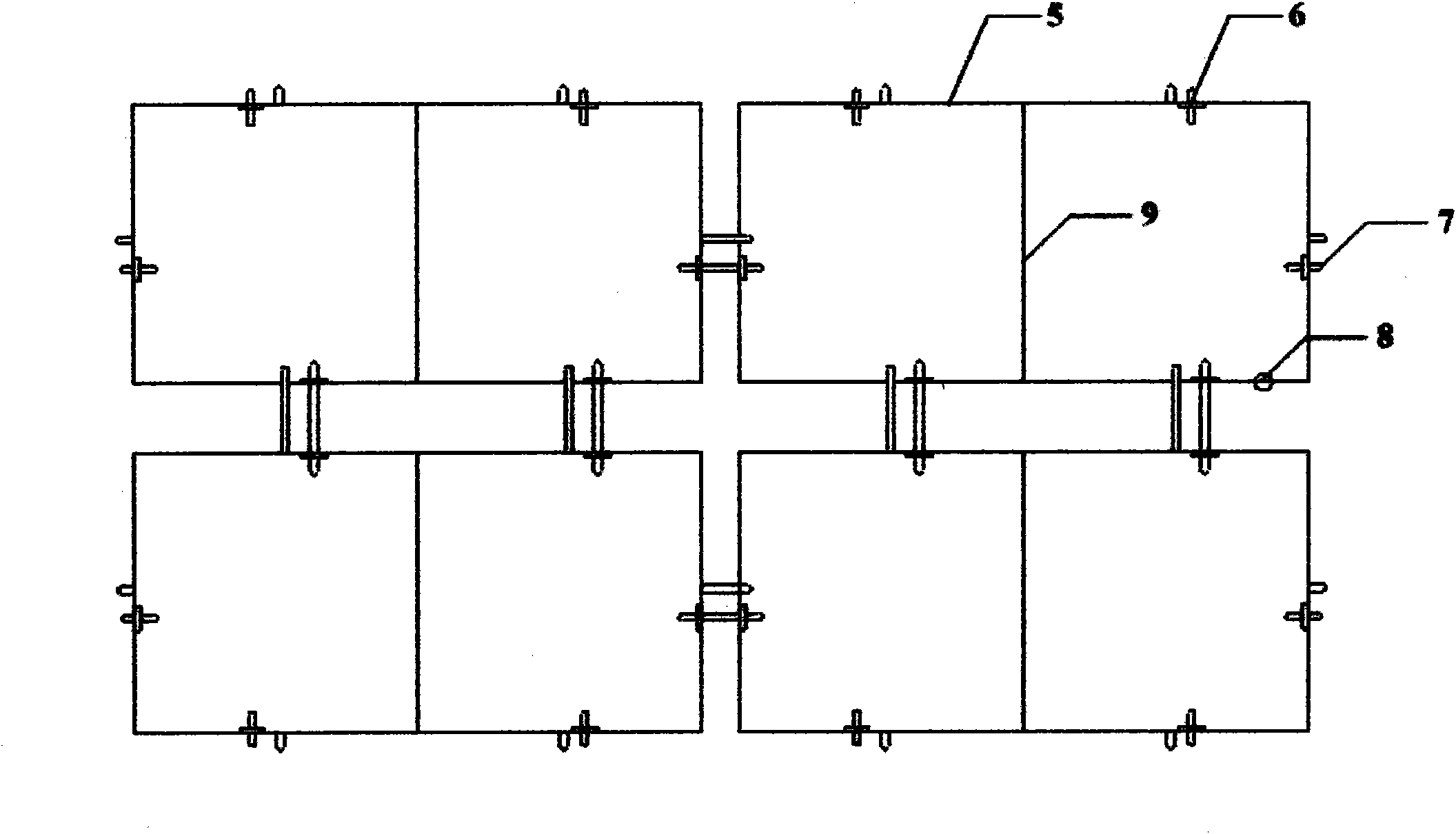

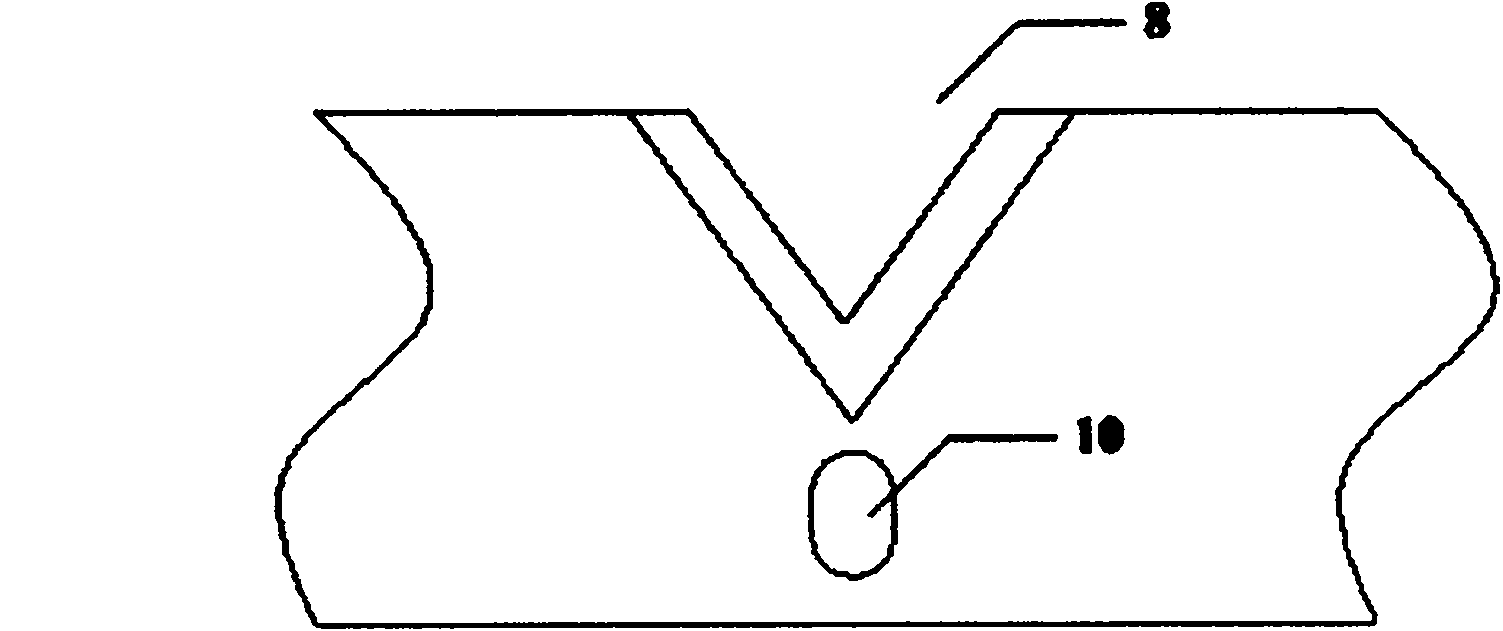

[0030] Such as Figure 1 to Figure 4 As shown, the hollow-out LED display screen provided by the present invention is composed of a fixed frame 1, a control box (not described in the figure) and a display part 2. The display part 2 and the control box are installed on the fixed frame 1, and the display part 1 and the control box The display part 2 is composed of a plurality of light strips 3, the light strips 3 are connected with the control box through the end cover 13, the end cover 13 is connected with the insertion slot in the control box through the connection line, and the end cover and the connection line One-piece structure. The end caps are respectively arranged at both ends of the light bar 3 , a concave V-shaped groove b11 is provided at the bottom of the light bar 3 , and a protruding lock 12 is provided on the side wall of the V-shaped groove b11 . Hollow gaps 4 are provided between two adjacent vertical light bars 3 , and the hollow ratio between two vertical li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com