Methods and systems for induction motor control

A technology for induction motors and control signals, applied in control systems, vector control systems, AC motor control, etc., can solve problems such as difficult decoupling, loss of torque linearity, and inability to properly maintain machine flux levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background or the following detailed description.

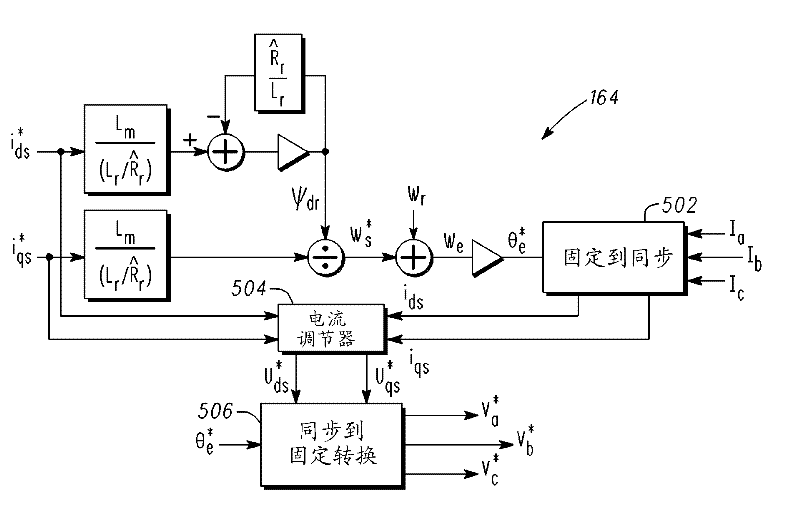

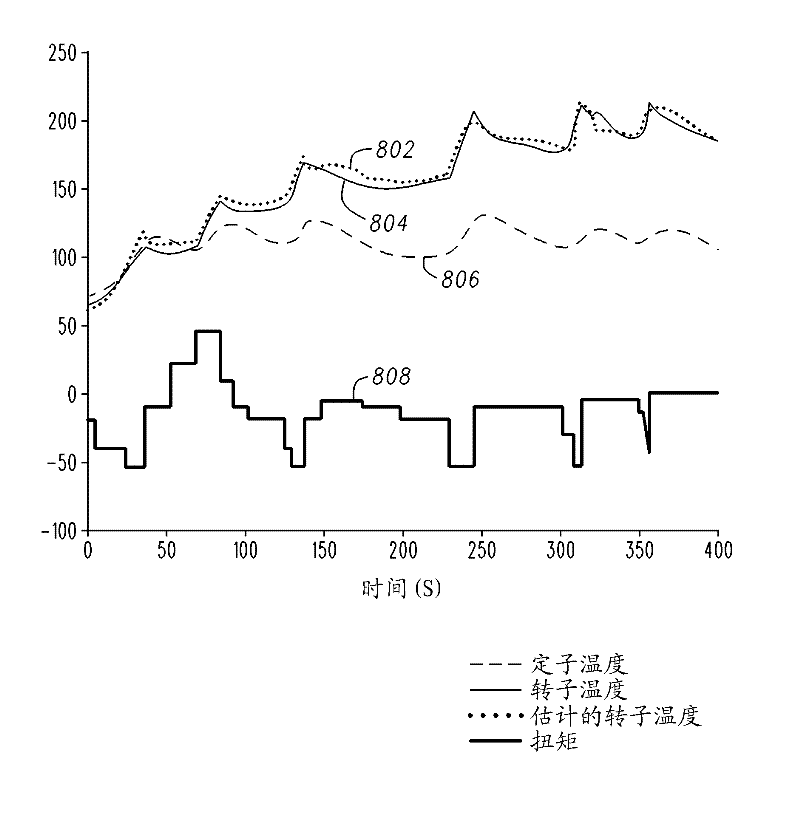

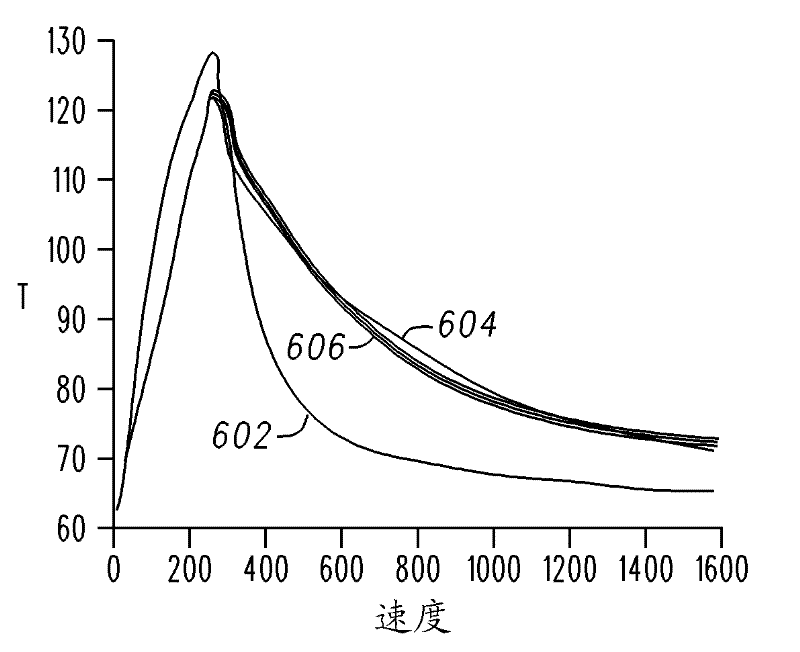

[0069] Broadly, the exemplary embodiments disclosed herein provide improved induction motor control. Specifically, the example systems and methods provide an improved estimate of rotor temperature, which in turn provides an improved estimate of rotor resistance. For example, the rotor temperature can be generated by a thermal model using the estimated rotor current and the temperature of the coolant or stator to provide a more accurate estimate, especially at low torque conditions. The estimated rotor resistance is then used as input to the IFOC module to provide improved operation of the induction motor.

[0070] figure 1 is a functional block diagram of an induction motor syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com