Multi-coil electromagnetic heating system and method

A heating system and heating method technology, applied in the field of multi-coil electromagnetic heating systems, can solve the problems of inability to change the output power distribution ratio and fixed power ratio, and achieve the effects of low production cost, small interference and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

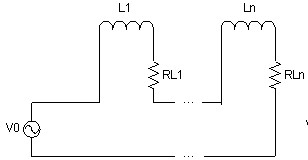

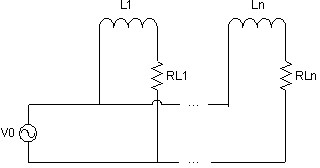

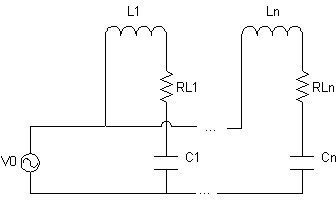

[0043] This example provides a multi-coil electromagnetic heating system, including: a power supply for selecting alternating currents of different frequencies, and at least two parallel working circuits; the working circuits are respectively connected to the power supply, including electromagnetic heating coils, capacitors and resistors; the power supply is capable of outputting an alternating current covering the resonant frequency range of the operating circuit.

[0044] This example includes at least two working circuits connected in parallel and connected to the power supply. The working circuit is formed by using an electromagnetic heating coil, a capacitor and a resistor in series. Wherein, the working circuit adopts working circuit 1...working circuit n, n is a natural number greater than or equal to 2, working circuit 1...working circuit n adopts electromagnetic heating coils, capacitors and resistors in series, and uses L1...Ln respectively Represents an electromagne...

Embodiment 2

[0052] Different from Embodiment 1, the multi-coil electromagnetic heating system described in this embodiment includes two working circuits connected in parallel and connected to the power supply.

[0053] On the basis of using the power supply to provide alternating currents of different frequencies, the two parallel working circuits are divided into a working circuit 1 and a working circuit 2, and the working circuit 1 is composed of an electromagnetic heating coil L1, a capacitor C1 and a resistor RL1 connected in series , the working circuit 2 is composed of an electromagnetic heating coil L2, a capacitor C2 and a resistor RL2 connected in series. When the power frequency is f1, the output power of the electromagnetic heating coil L1 is PL1L, and the output power of the electromagnetic heating coil L2 is PL2L , PL1L / PL2L>>1; when the power frequency is f2, the output power of the electromagnetic heating coil L1 is PL1H, the output power of the electromagnetic heating coil ...

Embodiment 3

[0056] The difference from Embodiment 2 is that the power source described in this embodiment adopts a high-frequency heating power source.

[0057] In this example, on the basis of utilizing the characteristics of the LC series resonant circuit, by changing the frequency of the power supply, high-frequency heating power supplies of different frequencies are provided, and high-frequency alternating currents of different frequencies are provided. Even if no relay is used, the power supply can be changed The high-frequency alternating current is provided, thereby changing the output power distribution ratio of the electromagnetic heating coil, and controlling different working circuits for multi-coil electromagnetic heating. The interference between the working circuits is small, the production cost is low, and the operation is simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com