Tread with improved drainage space

A drainage volume, tread technology, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] For ease of reading, the same reference number is used for all alternatives described below when the reference number indicates an element having the same structure and performing the same function.

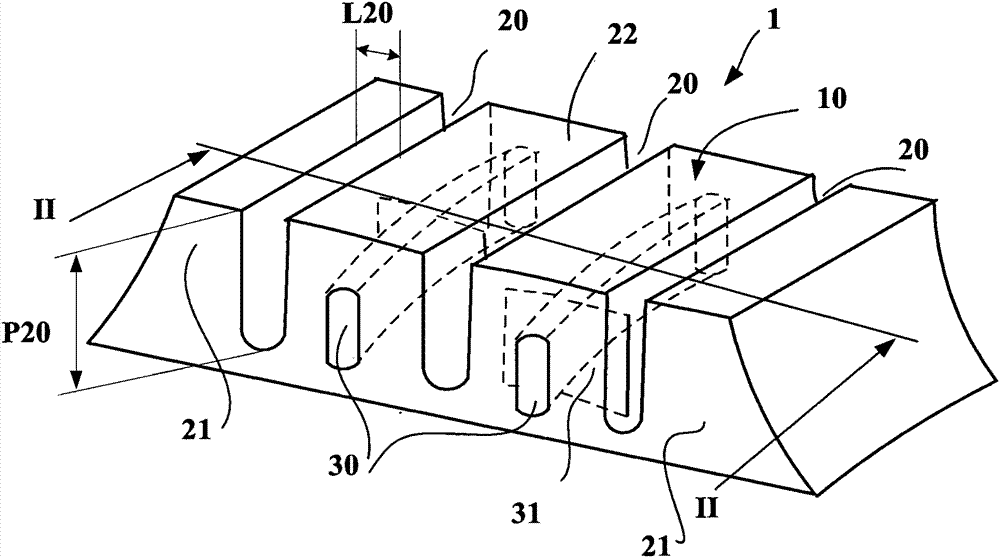

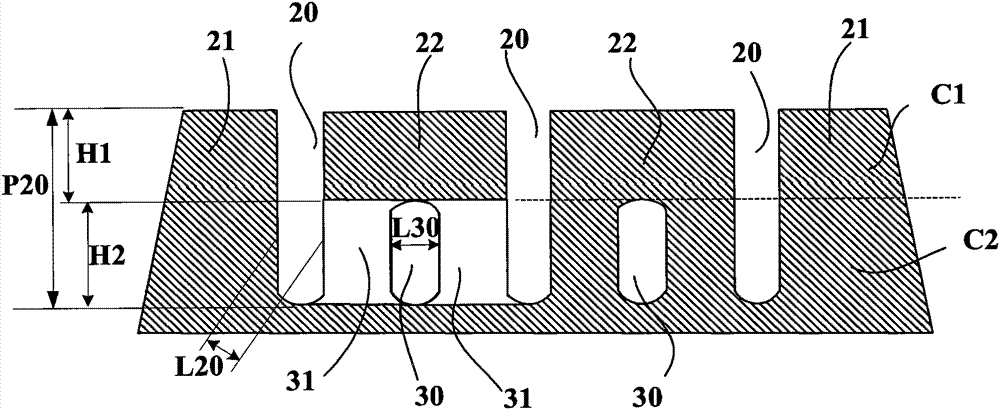

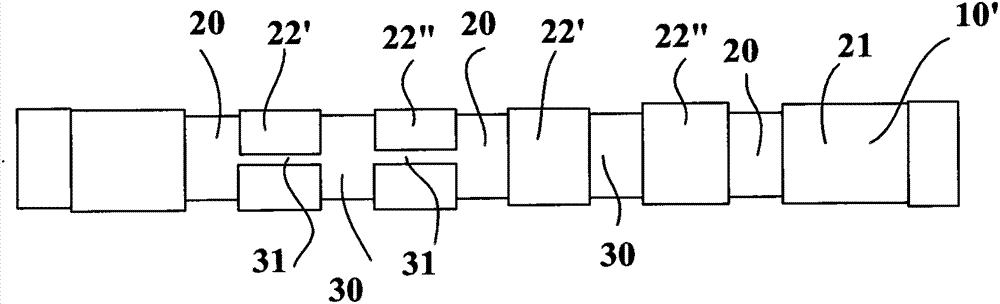

[0033] figure 1 A partial view of a tread band 1 constructed according to the invention is shown. This tread 1 comprises a tread pattern formed by three main grooves 20 oriented circumferentially and delimiting intermediate ribs 22 and edge ribs located axially on each side of these intermediate ribs These grooves open to the tread surface 10 intended to come into contact with the road surface during running. The tread 1 described here corresponds to the tread in new, unworn condition. In this condition, all grooves have the same depth P20 and width L20, which is particularly useful for water present on the road surface in rainy conditions. It can also be seen in this first figure that there are circumferentially oriented channels 30 in the two intermediate ribs 22 ; mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com