Brake-generator device

A technology for power generation devices and automobiles, which is applied in the directions of electromechanical devices, electrical components, and electric components, and can solve problems such as unfavorable energy conservation and environmental protection, easy wear and tear, and cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 ,,: and 、、 and other 。, and ,,,。、 and 。,,,,,。, approach , Embodiment approach :,,,, to 。 Embodiment 2

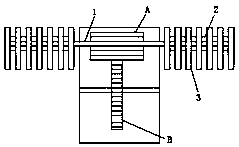

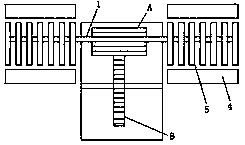

[0006] The main structure of the novel braking power generation device of the present invention uses the principle of magnetic induction to realize the braking of the automobile and converts kinetic energy into electric energy during the braking process, such as figure 1 As shown, it includes a transmission shaft 1 arranged horizontally, and the transmission shaft 1 is meshed with the output transmission gear B in the automobile gearbox through the transmission gear A located in the middle, and the two ends of the transmission shaft 1 are respectively equipped with The rotating rotor assembly 2, the outer periphery of the rotor assembly 2 is correspondingly provided with a stator assembly 3, the stator assembly 3 and the rotor assembly 2 constitute a generator device, so that when the generator device is working, the The kinetic energy output by the rotation of the transmission shaft is converted into electric energy. In the process of power generation, the transmission mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com