Large power transformer oil tank welding flip frame

A technology for power transformers and reversing frames, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low turnover rate of equipment and production efficiency, troublesome adjustment of welding seam position, and occupation of cranes, etc., to achieve Improve efficiency, reduce the occupation of lifting equipment, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

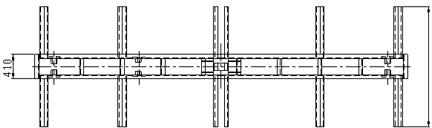

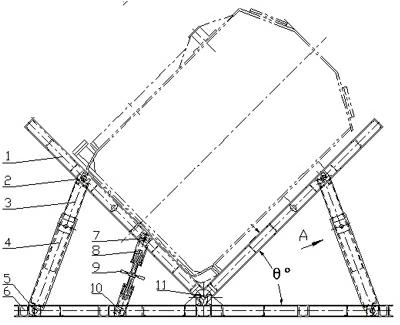

[0016] Large power transformer oil tank welding overturn frame, including frame body 1, base 6, adjustable length support shaft, adjustment shaft 8, adjustment screw 9, the middle part of the frame body is hinged on the base, and the two ends of the frame body are respectively equipped with The adjustable length support shaft on the base is also provided with an adjustment shaft and an adjustment screw between the frame and the base; the rotation of the adjustment screw is converted into the angle required by the working surface of the frame, and the required angle is fixed. Then put the fuel tank on the working surface of the frame body, and carry out the welding on the flat welding position.

[0017] In the embodiment, two sets of the present invention support the two ends of the fuel tank. The frame body 1 is a fixed bracket welded by channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com