Large diameter double wall corrugated water pipe

A large-diameter, water pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high production cost, inconvenient use, unfavorable installation, etc., achieve low production cost, convenient installation and use, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

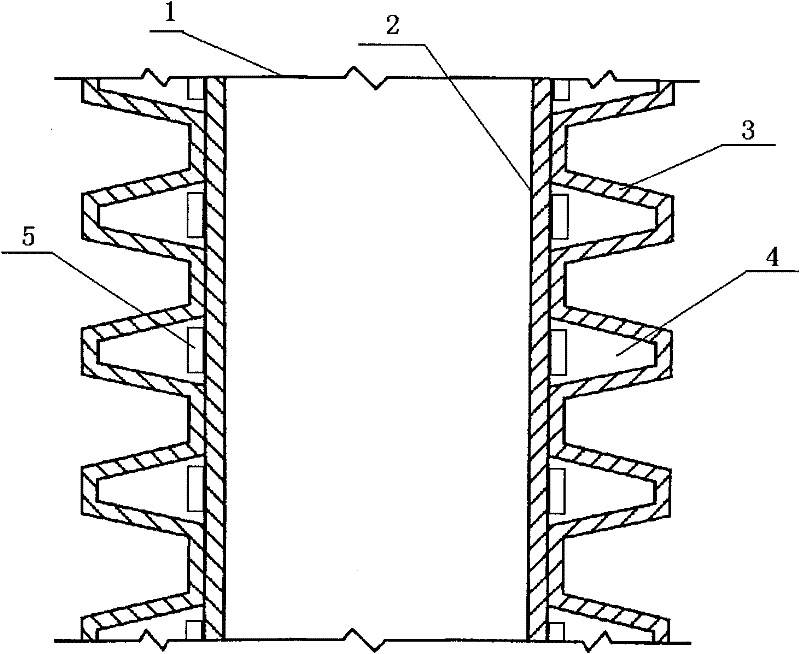

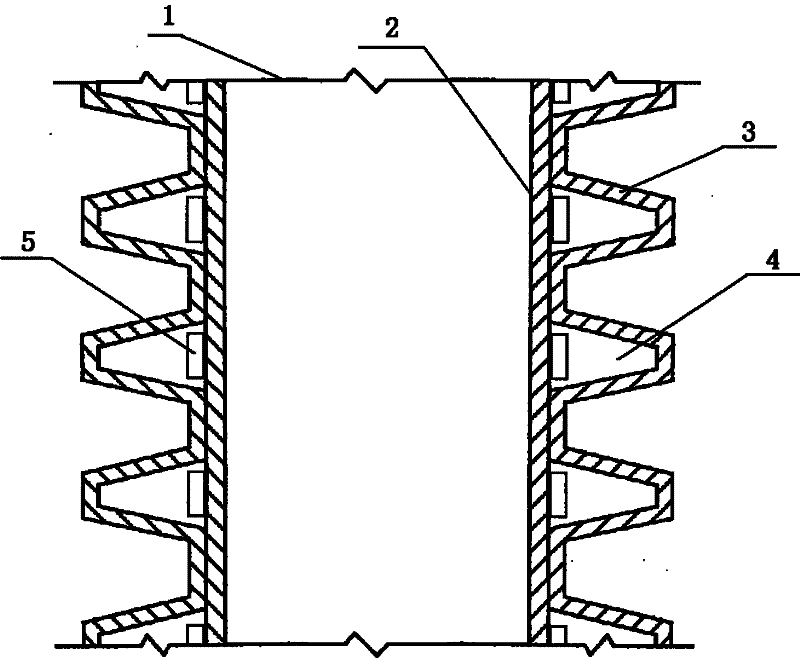

[0010] Example according to figure 1 It can be seen that a large-diameter double-wall corrugated polyvinyl chloride water pipe 1 has a pipe wall composed of two layers inside and outside, the inner pipe wall 2 is smooth, the outer pipe wall 3 is trapezoidal corrugated, and the cavity 4 between the inner and outer walls A steel hoop 5 is provided, and the trapezoidal bottom groove of the outer wall is connected with the inner wall as a whole.

[0011] The embodiment is only for the convenience of understanding the technical solution of the present invention, and does not constitute a limitation to the protection scope of the present invention. Any simple modification, equivalent change and Modifications still fall within the protection scope of the present invention.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap