Digital-control oil and water pressurizing measuring tank

A metering box, oil-water technology, applied in the field of oil transfer stations, can solve the problems of large floor space, long construction period, poor adaptability, etc., and achieve the effect of small floor space, fewer operators, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

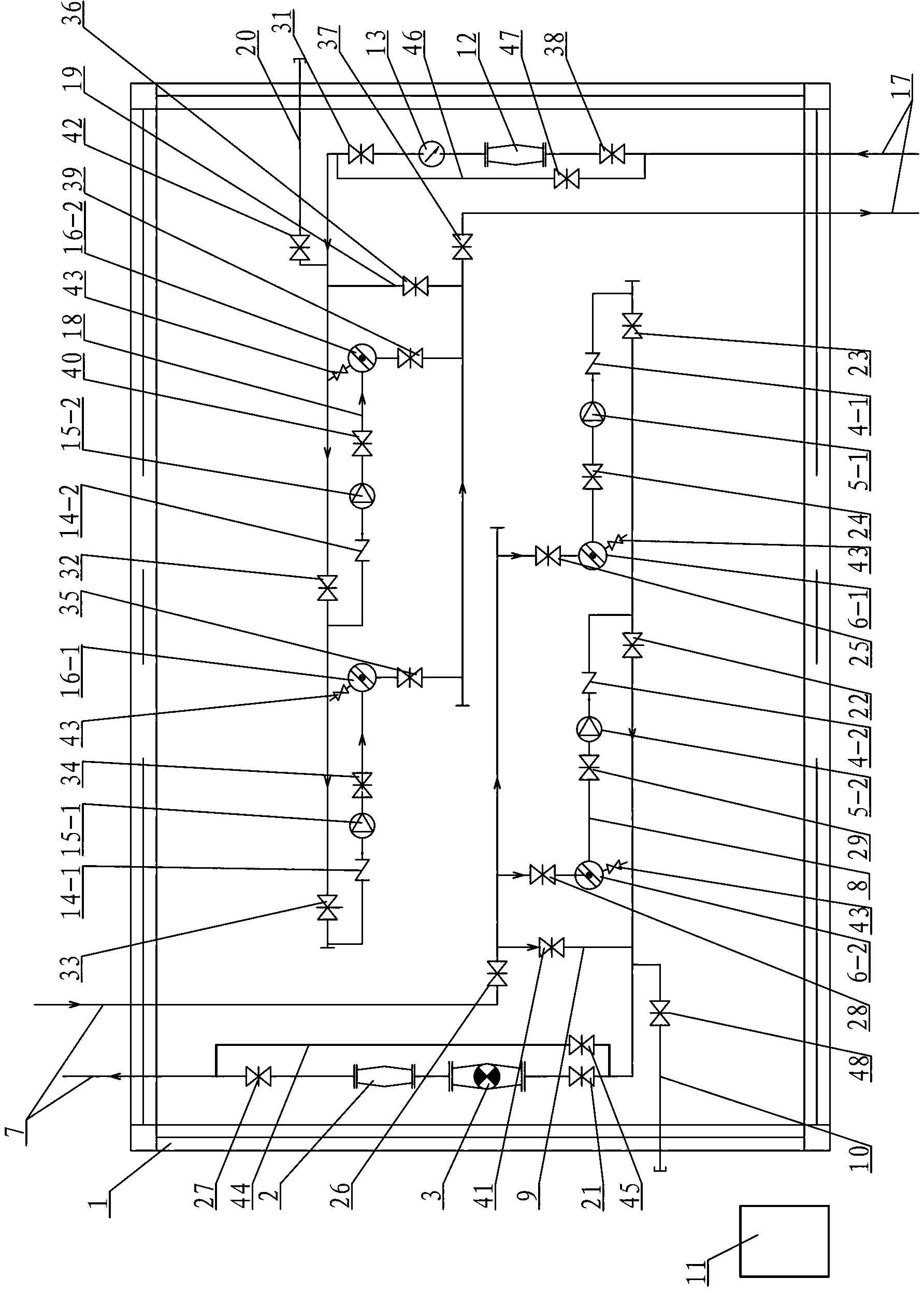

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment includes a box body 1, a first flow stabilizer 2, an oil flow meter 3, a first check valve 4-1, a second check valve 4-2, and a first oil delivery pump 5- 1. The second oil delivery pump 5-2, the first filter 6-1, the second filter 6-2, the oil pipe 7, the first connecting pipe 8, the second connecting pipe 9, the digital frequency conversion equipment 11, the second flow stabilizer 12 , water mixed flowmeter 13, the third one-way valve 14-1, the fourth one-way valve 14-2, the first water delivery pump 15-1, the second water delivery pump 15-2, the third filter 16-1, the first Four filters 16-2, water pipe 17, the third connecting pipe 18, the fourth connecting pipe 19, the first valve 21, the second valve 22, the third valve 23, the fourth valve 24, the fifth valve 25, the sixth valve 26, The seventh valve 27, the eighth valve 28, the ninth valve 29, the tenth valve 30, the el...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that it also adds an external oil pipe 10 and a twenty-third valve 48, and one end of the external oil pipe 10 is connected between the second connecting pipe 9 and the first valve 21 On the oil pipe 7 , the other end of the external oil pipe 10 is arranged outside the casing 1 , and the twenty-third valve 48 is installed on the external oil pipe 10 . The external oil pipe 10 plays the role of emptying the sewage pipeline and cleaning the pipeline. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment. The difference between this embodiment and the first embodiment is that it also adds an external water pipe 20 and a twenty-second valve 42. One end of the external water pipe 20 is connected between the fourth connecting pipe 19 and the eleventh valve 31. On the water pipe 17, the other end of the external water pipe 20 is arranged outside the casing 1, and the twenty-second valve 42 is installed on the external water pipe 20. The external water pipe 20 plays the role of emptying the sewage pipe and cleaning the pipeline. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com