Device for preparing thin-strip resilience body and application thereof

A technology for preparing devices and projectiles, which is applied in the field of testing, can solve the problems that manufacturers and users have no way to test, and achieve the effect of fast measurement work, easy mastery, and simple measurement technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

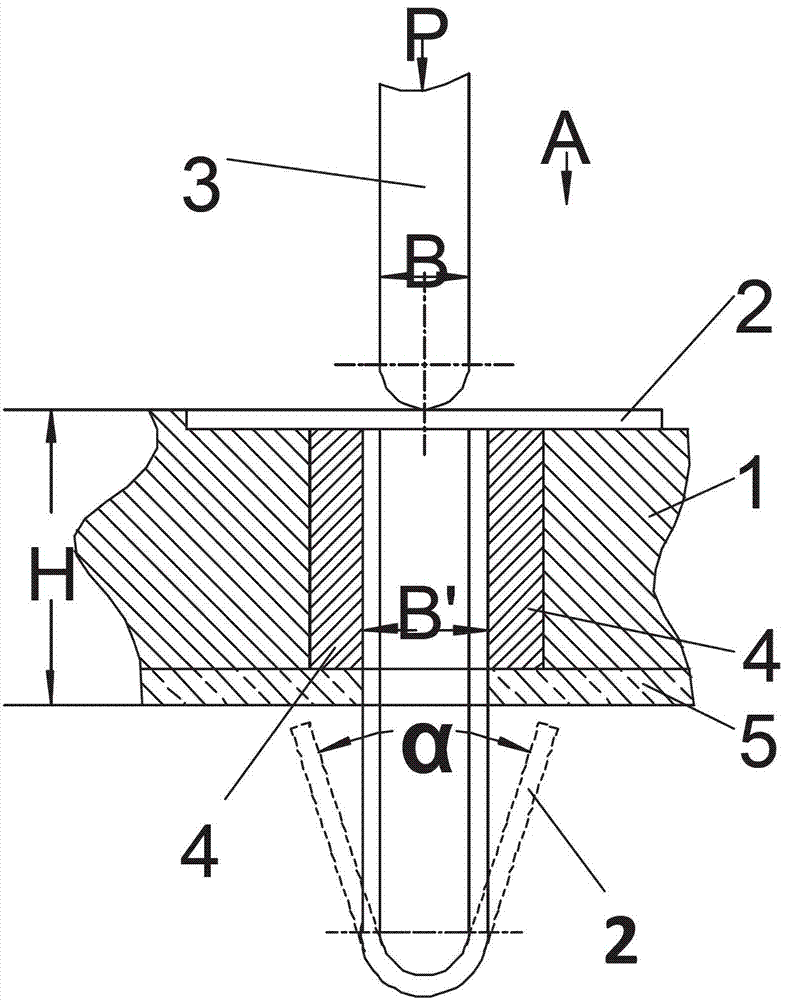

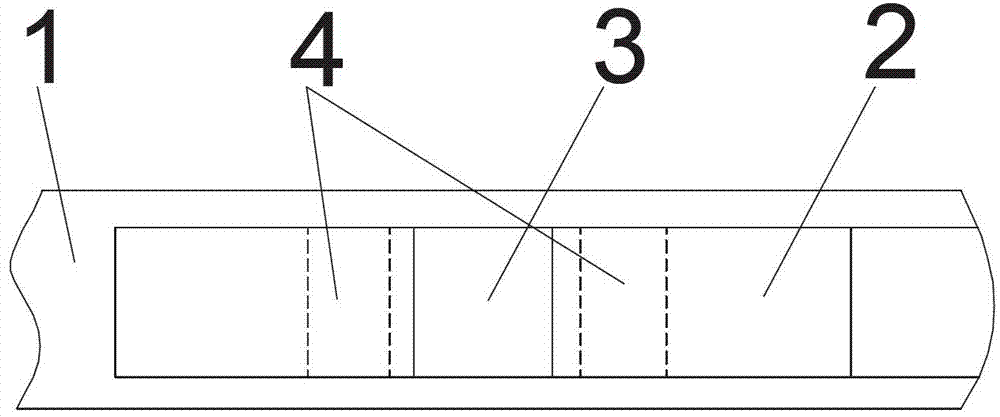

[0015] Such as figure 1 , 2 As shown, 1 in the figure is an integral female mold, 2 is a tinned copper strip with a specification of 0.2×1.6mm, the copper substrate is T1Cu, 99.95% pure, and the thickness is 0.153mm. Both surfaces of the thin strip are plated with Sn alloy solder. After being cut into 50mm lengths, put it into the upper groove of the female mold 1, and push the left end to the step. 3 is punch, and 4 is elastic sheet, selects the thick vacuum rubber of 5mm for use, wide 15mm, glues on the cavity wall of female mold with glue, and the thickness of B is 8mm. B' is also 8mm wide, with an interference of 0.306mm, and H is 68mm; 5 is the supporting plate, which is located at the lower end of the female mold.

[0016] Use a punch press to press down the punch and move in the direction of the P arrow at a speed of 16mm / min. The α angle of the punched formed part to be tested is 15o. 30 pieces were punched under the same conditions, and the measured α angles were a...

Embodiment 2

[0018] The situation is basically the same as in Example 1, except that the copper substrate is annealed more fully, and the punch is pressed manually. Other conditions remain unchanged, the measured rebound angle α is 10o.

Embodiment 3

[0020] The situation is basically the same as that of Example 1, except that the grade of the copper substrate is T2 (999% purity), the annealing conditions of copper are the same as T1, and other conditions are also the same as Example 1. 20o.

[0021] Two conclusions are illustrated through the above examples: one is that as the purity of the copper substrate increases, the α angle will become smaller under the same annealing conditions; the other is that the purity of the copper substrate can be changed from 99.95% to 99.99%. It is reflected in the value of α.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com