Thin Absorbent Articles

An absorbent and article technology, applied in the fields of absorbent pads, medical science, clothing, etc., can solve the problems of easy distortion and high cost, and achieve the effect of not easy to distort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

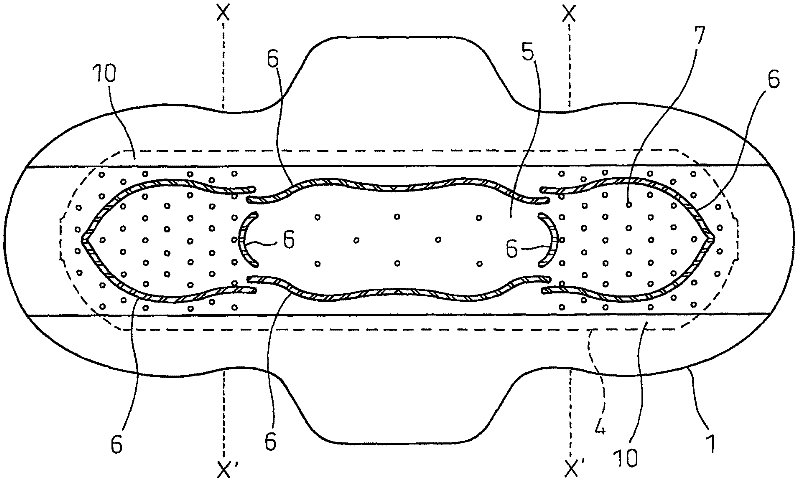

[0053] figure 2 It is a plan view and A-A' line sectional view showing one embodiment of the sanitary napkin of the present invention. exist figure 2 Among them, the extruded grooves 6 are continuously arranged on the central region 5 of the absorber, and are arranged in the front and rear of the central region in a manner of being continuous with the central region in the longitudinal direction, and the point-like extruded parts 7 are arranged at the same interval It is arranged on substantially the entire surface of the absorber 4 . figure 2 The sanitary napkin of is manufactured as follows.

[0054] First, prepare the following parts.

[0055] (1) Absorber 4

[0056] Crushed pulp (basis weight 180g / m 2 ) and superabsorbent polymer (basis weight 30g / m 2 ) roughly evenly dispersed, with a paper towel (basis weight 15g / m 2 ) wrapping, and then punching so that the thickness of almost the entire surface becomes about 2mm. The length of the absorbent body after punchi...

Embodiment 2

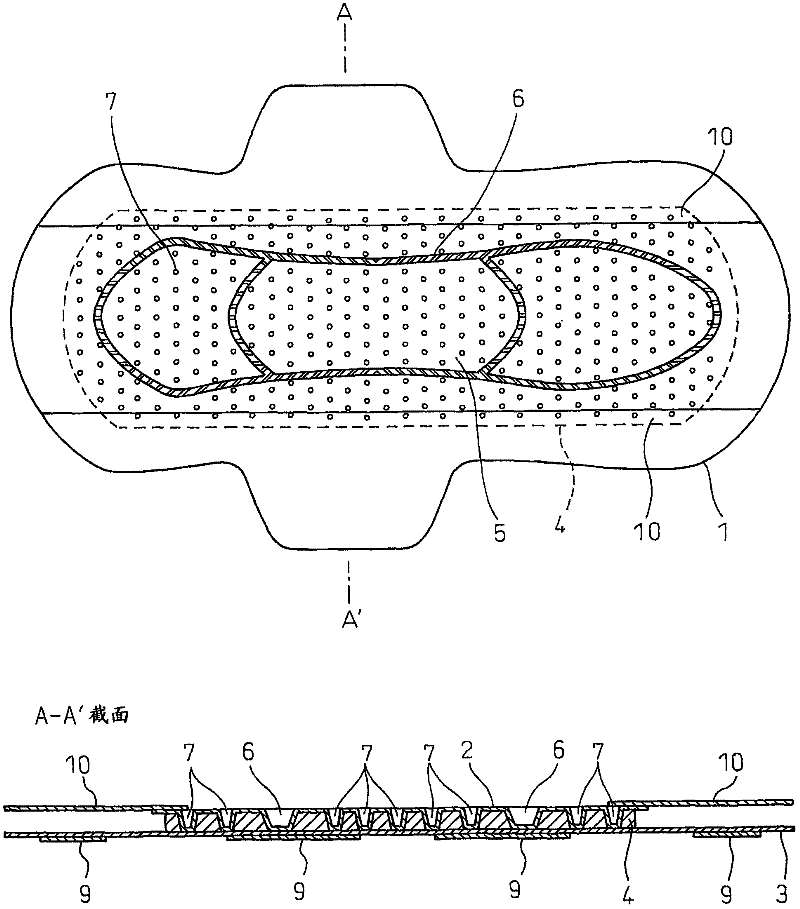

[0068] image 3 It is a plan view and A-A' line sectional view showing one embodiment of the sanitary napkin of the present invention. exist image 3 Among them, the extruded grooves 6 are continuously arranged in the central region 5 of the absorber, and are arranged in the front and back of the central region so as to be continuous with the central region in the longitudinal direction. In addition, the dot-shaped pressed portions 7 are arranged on the substantially entire surface of the absorber 4 at intervals that are sparse in the vicinity of the center of the absorber and dense in the front and back regions of the vicinity of the center. exist Figure 4 shown in image 3 An example of a partially enlarged view of the A-A' line section of . exist Figure 4 In this case, the thickness (i.e., distance b) of the part having the point-like pressing part 7 near the center of the absorber is the same as the thickness (i.e., distance b') of the part having the point-like pre...

Embodiment 3

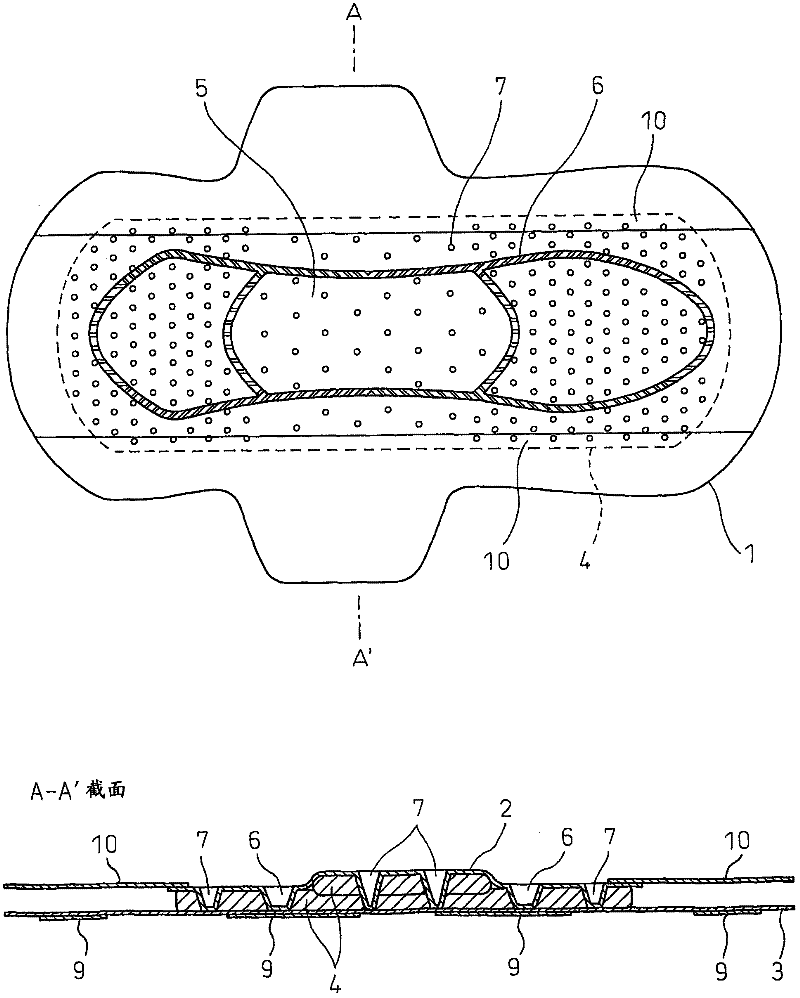

[0073] Figure 5 A top view showing one embodiment of the sanitary napkin of the present invention is shown. exist Figure 5 Among them, the extruded grooves 6 are continuously arranged on the central region 5 of the absorber, and are arranged in the front and rear of the central region in a continuous manner with the central region in the longitudinal direction, and the dot-shaped extruded parts 7 are arranged at the same intervals only It is arrange|positioned in the area|region of the front and rear near the center of an absorber.

[0074] The components used to manufacture the sanitary napkin shown in this embodiment are all the same as those in Embodiment 2.

[0075] Carry out heat embossing processing identically with embodiment 1, in such as Figure 5 Extruded grooves 6 and point-shaped extruded portions 7 are formed at the positions shown. The dotted squeezed portion is formed by compressing 50% to 99% of the thickness of the absorber. The width of the extruded gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com